Single Girder Gantry Crane

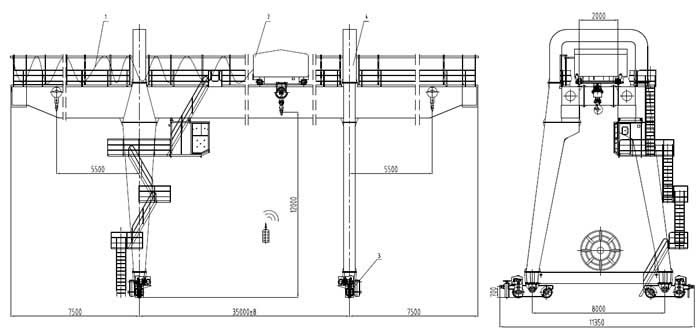

Double Girder Gantry Crane

Portable Gantry Crane

Rubber Tyred Crane

Tonnages & Specifications

Uses & Applications

Philippines

Pakistan

Saudi Arabia

Bangladesh

UAE

Bahrain

Morocco

Australia

Malaysia

Indonesia

Singapore

Thailand

Crane for Sale Qatar

Overhead Crane Nigeria

Crane Uzbekistan

Algeria

Kenya

Crane for Sale Zambia

Cranes & Hoist for Sale Uganda

South Africa

Ghana

Congo

Vietnam

Serbia

Kazakhstan

Bolivia

Russia

Brazil

Jordan

Egypt

UK

Oman

Spain

Jamaica

Guinea

Dominica

Laos

Portugal

Kuwait

Ethiopia

Mongolia

Azerbaijan

Trinidad and Tobago

Poland

Box girder gantry crane for outdoor application

Box girder gantry crane for outdoor application Box girder gantry crane for indoor application

Box girder gantry crane for indoor application Main girder - main part of box beam double girder gantry crane

Main girder - main part of box beam double girder gantry crane Supporting leg - main part of box beam double girder gantry crane

Supporting leg - main part of box beam double girder gantry crane Gantry trolley - main part of box beam double girder gantry crane

Gantry trolley - main part of box beam double girder gantry crane Crane wheel - main part of box beam double girder gantry crane

Crane wheel - main part of box beam double girder gantry crane Crane driving - main part of box beam double girder gantry crane

Crane driving - main part of box beam double girder gantry crane Gantry cable reel - main part of box beam double girder gantry crane

Gantry cable reel - main part of box beam double girder gantry crane