Wire Rope Hoist, Cable Hoist & Wire Hoist

Electric Wire Rope Hoist 0.5 -32 Ton

Electric wire rope hoists for sale. Types of electric cable hoists, ie. 1 /2 speed, low headroom, explosion-proof rope hoist for sale, good hoist price.

Electric wire rope hoists for sale. Types of electric cable hoists, ie. 1 /2 speed, low headroom, explosion-proof rope hoist for sale, good hoist price.

CD/MD wire rope hoist is the economical electric wire rope hoist, with single or double lifting speed. Need a single or double speed hoist? Check now.

Stationary electric cable hoist used for hoisting or pulling as winch or on double girder hoist trolley . Check stationary electric cable hoist now.

Motorized trolley electric wire rope hoist can be used on single girder crane, I beam or monorails, hot sale electric rope hoist at very good rope hoist price.

CD/MD wire rope hoist is the economical electric wire rope hoist, with single or double lifting speed. Need a single or double speed hoist? Check now.

Low headroom & Low profile electric wire rope hoist, affordable wire rope hoist for low ceiling / low clearance workshop for heigher lifting. Check now.

1 ton, 3ton, 5 ton, 10 ton, 16 ton electric low profile trolley hoist for sale, good price. Wire rope low profile hoist to save your workshop space.

Electric wire rope hoist with low profile design increase your lifting height at space limited worshop. Low headroom or low profile hoist for sale, Good hoist price.

10 ton wire rope low headroom hoist for sale good price. Electric hoist with low headroom design save your working space & for better hook height. Check now.

Explosion proof wire rope hoist, explosion proof parts & components to ensue safety in explosive & combustible conditions. Explosion proof hoist for sale.

Yuantai explosion proof hoist, flame proof hoist modular parts, convenient to use, maintain and repair; high standard, reliable & safe hoist. Check now!

Wire rope explosion proof electric hoist with lifting height of 12 to 20 meters. Customized explosion proof electric hoist available. Get your wire rope hoist design!

Explosion proof wire rope hoist 10 ton for sale. Safer wire rope hoist, Higher explosion proof protection, Better rope hoist price. Check bettercrane.com.

Wire rope hoists are very popular material handling equipment that are used in a variety of industries today. We have summarized exactly what they are, the main types of wire rope hoists available, the basic structure and components, as well as the various advantages they have over other electric hoist systems for your reference. If you have any need of electric wire rope hoist, please feel free to contact us. All is for your reference to get your preferred electric hoists.

An electric wire rope hoist is a lifting equipment that is commonly used in environments where heavy duty lifting occurs, such as heavy foundries, factories, and manufacturing plants. There electic wire rope hoists are just like the general use electric chain hoist, which are both very frequently to seen for material handling. However, because wire ropes have greater SWLs (safe working loads), they are frequently better suited for heavy lifting than conventional electric chain hoists.

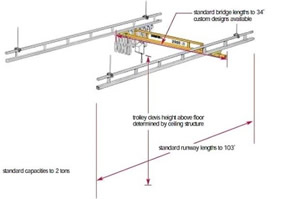

In today's industry, a variety of wire rope hoist systems are used. There are double girder crab hoisting systems, single girder /monorail rope hoist, foot or base mounted, and standard headroom/monorail hoisting systems and low headroom type, general use one & explosion proof use one. Although they are all adopted for loads and material handling, they differ slightly in their application.

They are typically used on single girder overhead crane systems which they are suspended under the botton flange of main girder. They are very economical and are the best choice for applications where there is no working height restriction under the beam. The wire rope hoists are equpped with their own trolley systems, to meet all your lifting requirement in 4 direction movements.The single girder wire rope hoists are usually used for loads handling with capacity of 20 tonnes and also Single speed and dual speed are optional .

This is the most versatile wire rope hoisting equipment available, with plenty of maneuverability. It is especially useful in environments that necessitate cross-movement. It can easily navigate through twists and turns and change its course when necessary. They are essential in large warehouses and manufacturing plants.

This kind of wire rope hoist is employed when the application just needs a hoist to manage vertical movement. The wire rope hoist is situated on the building's roof, and the material is raised at various floor levels. It is foot mounted in the case of a wire rope hoist and top hook mounted in the case of a chain hoist.

They are also extremely useful because they can be used as either a static or mobile lifting hoist, giving them a wide range of applications in industrial settings. This is due to the fact that the hoists can be attached to a gantry system or mounted to trolley systems like crab unit trolleys.

These double girder wire rope hoist systems are ideal for tasks that require heavy lifting. On double-girder cranes, crab unit systems run along the top edge of both girders. The crab hoist units enable the greatest possible height of lift under the beam. The disadvantage of these wire rope crab hoists is that because the system runs along the top edge of the girders on which they are installed, more height is required above the girder.

Explosion proof and flame proof wire rope hoist

The name accurately describes its utility, which is useful in high-risk, fire-prone environments. Chemical plants and oil refineries are two common applications for this explosion proof Hoist. Besides, they are also widely used in food processing workshop, painting workshops and other hahazardous applications. It functions similarly to a standard wire rope hoist and can be electrically operated via a handheld pendant.

Check with your team to see what weight has to be lifted on the job site. Choose an electric wire rope hoist with a capacity greater than what you need on a daily basis. This lowers the possibility of mishaps while also enhancing the electric hoist's longevity. You can improve the safety, quality, and durability of your work site with this straightforward maintenance. By selecting the appropriate product, you can speed up your job and be prepared should you later need to lift additional weight.

The quantity of lift anticipated each day must also be taken into account. As important as other parameters, tensile strength is needed for various weights and turn counts. The required tensile strength varies depending on the material. Therefore, before purchasing a wire rope hoist , it is important to consider the anticipated number of lifts and select the appropriate hoist type.

A company's success depends on its ability to expand and advance. For improved profits over time, one must broaden their perspective, which calls for better investing. So you consider buying a hoist as an investment for your company. Make sure to factor future needs into your investment to ensure that it pays out in the long run.

When purchasing a wire rope hoist, the most frequent concept that people have is that it must be strong, durable, and robust enough. However, this is not the best course of action. Instead, you should determine what are the features that needed to be added to your hoists based on your lifting height and the working site conditons, and if there are any realistic options, you should place a strong emphasis on those. Electric wire rope hoists with expert control and reinforced ropes are more suitable than those that are merely hardy and rugged. Different needs call for different levels of flexibility, grip, and features . Prioritize your needs, then buy the hoist that best meets them.

Electric wire rope hoists are made up of electric motors, gearboxes, a rope drum with rope guides, an electric panel, and a large wire rope attached to a hook. Electric wire rope hoists are used to transport large objects weighing 500 kg to 20 tons in a variety of conditions such as extreme heat while welding, over burners and furnaces, or in an acidic atmosphere.

Here are some things to keep in mind when using an electric wire rope hoist in your industrial sectors.

Dongqi was founded in 1984, and since then, we have built a reputation for producing high-quality heavy duty material handling equipment. We have been manufacturing and supplying equipment such as electric hoists and overhead cranes throughout the world wide market.

Dongqi Crane Factory has more than 30 years of manufacturing experience and is the top crane manufacturer and supplier in China.

Here, we can provide you with the best quality and the most competitive price.

we have over 30 years of experience engineering, manufacturing, and installing overhead crane systems.

Yuantai Crane can provide overall services for all types of industries cranes, and the main services are as follow:

|

Crane project design Cranes designed by Yuantai Crane will solve any of your crane problems and material handling problems without spending any unnecessary expenditures. |

|

Crane Installation EASAY installation, wonderful working performance. Yuantai Crane can provide on-site crane installation services and our crane engineers will be at your services when necessary. |

|

Lifetime Maintenance Crane maintenance from Yuantai Crane ensures your safety and working efficiency. |

|

Crane operator Training Yuantai Crane training includes crane operation, maintenance and inspection, and crane spare parts, etc. |

|

Technical support The powerful technical support of Yuantai Crane will solve your crane technical problems. |

|

Crane parts Yuantai Crane parts will renew your cranes. |

Need Latest Crane Price? Please leave us the required Crane's Capacity, Lifting Height, Span, Travelling Length & Voltage for Quick Quotation.