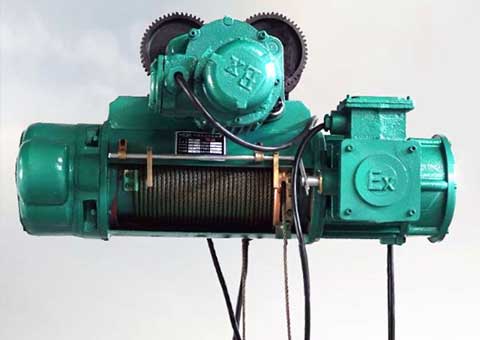

Explosion proof, Flameproof, Safe Hoist

Exploison Proof Wire Rope Electric Hoist 0.5 -32 Ton

Explosion proof wire rope hoist for sale. High safety explosion-proof rope hoist for chemical, mining, oil and gas and other industrial applications.

Explosion proof wire rope hoist for sale. High safety explosion-proof rope hoist for chemical, mining, oil and gas and other industrial applications.

An explosion proof electric hoist is a type of compact and light material lifting equipment. The explosion proof hoist is lightweight, compact, and has a high lifting capacity. When the workshop is filled with explosive air , substances or combination, it is a useful hoisting equipment for improving working conditions and labor productivity while assuring safety.

The "flameproof" is the explosion proof type of electric wire rope hoist equipment designed and built in accordance with the explosion proof standard. The exposed explosion proof constructions and parts and components of the electric hoist are built of unique non-sparking materials, ensuring safe and reliable explosion proof performance.

Yuantai Crane' explosion-proof electric hoist has the following benefits:

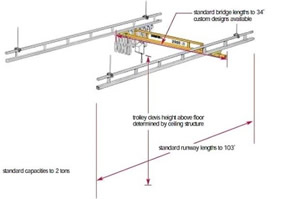

Explosion proof electric hoists can be equipped with electric travelling trolley on i-beam tracks for linear or curve operation, based on the application conditions and lifting requirements, equipped on explosive proof single girder suspension cranes or explosion proof single, double girder bridge cranes or other types of overhead crane It can also be used for just for vertical hoisting which are mounted on the bracket or supporting structure.

The explosion proof hoists passed the explosion proof performance test of the Ministry of Mechanical Industry's explosion proof electrical product quality supervision and inspection center, and the explosion proof certificate are provided.

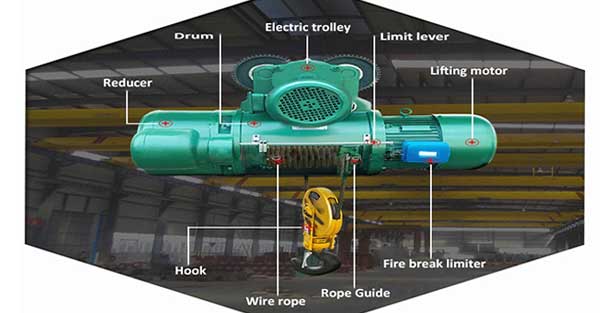

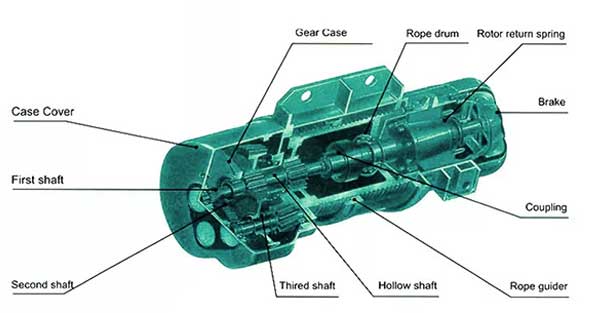

The explosion proof grade of explosion proof electric hoist is DIIBT4 and DIICT4, the exposed explosion proof parts and components of the wire rope hoist are made of special sparkless materials to ensure safety. The electric hoist are mainly consisted of the motor, electrical appliances, electric travelling wheels or not included in stationary design, rope guide, hook, operation handle, etc. All of the electric hoists and components used are for the hazardous application with explosion proof features to ensure safe and reliable performance.

Explosion proof rope guide

Explosion proof rope guide Explosion proof travelling wheel

Explosion proof travelling wheelExplosion proof wire rope electric hoist is on the basis of ordinary wire rope electric hoist, motor, electrical appliances and some parts to take explosion proof measures, suitable for containing combustible gas, steam and air combined to form a spark easily flammable and explosive work place (such as coal mine, pharmaceutical factory, chemical plant, etc.).

Explosion proof wire rope electric hoist is developed on the basis of a standard cd/md wire rope electric hoist. The main parts of the explosion proof electric hoist such as motor, electrical appliances, and other parts are designed with explosion proof features, making it suitable for applications with combustible gas, steam, and air combined to form a spark easily flammable and explosive work environment. They are widely used in applications such as such as coal mine, pharmaceutical factory, chemical plant, etc.

BCD explosion proof electric wire rope hoist adapts to the environment in factory that has explosive gas formed by inflammable gas, steam, and air of which explosion proof grade is less than B grade or C grade and ignition group is more than T4(135°C)group. and the explosion proof hoist are applicable to 1 area or 2 area.

The working temperature range is - 25 °C to 40 °C, making it ideal for indoor application; when used outdoors, protection measures should be provided.

Yuantai explosion proof hoist, flame proof hoist modular parts, convenient to use, maintain and repair; high standard, reliable & safe hoist. Check now!

Inquiry Online Leave a MessageWire rope explosion proof electric hoist with lifting height of 12 to 20 meters. Customized explosion proof electric hoist available. Get your wire rope hoist design!

Inquiry Online Leave a MessageExplosion proof wire rope hoist 10 ton for sale. Safer wire rope hoist, Higher explosion proof protection, Better rope hoist price. Check bettercrane.com.

Inquiry Online Leave a MessageWhat is an explosion proof hoist?What is explosion proof equipment?What is explosion proof classification?What is explosion proof rating? Contact us today!

Explosion proof hoist is a kind of electric hoist crane which is easy to use and transport. Working with other types of explosion proof overhead cranes, they are widely use in hazardous applications to ensure safety.

Explosion proof electric hoist can be widely used in oil, petrochemical, oil station, oil depot, gas production, chemical industry, military industry, electric power, mine, electronics, railway, etc. When products clash in the operation, there is no mechanical spark; effective prevention of fire incidents; and ensuring the protection of state property and individuals. It is also a must-have special tool for mechanical manufacturing and maintenance.

Yuantai Crane's explosion-proof electric hoist offers the following features:

On hoisting motor

Lifting reducer

On hook

Operation

|

Specifications, main technical parameters and dimensions of explosion proof electric hoist |

|||||||||||

|

model |

BCD ( Single Speed) B MD ( Double Speed) |

||||||||||

|

Lifting capacity |

t |

0.5 ton |

1 ton |

2 ton |

3 ton |

5 ton |

10 ton |

16 ton |

|||

|

Lifting height |

m |

6/9/12 |

6/9/12/18/24 |

6/9/12/18/24 |

6/9/12/18/24 |

6/9/12/18/24 |

6/9/12/18/24 |

6/9/12/18/24 |

|||

|

Lifting speed (fast / slow) |

M / min |

8(0.8) |

8(0.8) |

8(0.8) |

8(0.8) |

8(0.8) |

8(0.8) |

4(0.4) |

|||

|

running speed |

M / min |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

|||

|

a wire rope |

Rope diameter |

mm |

4.8 |

7.4 |

11 |

13 |

15.5 |

15.5 |

17.5 |

||

|

Filament diameter |

mm |

0.22 |

0.34 |

0.5 |

0.6 |

0.7 |

0.7 |

0.7 |

|||

|

|

structural style |

mm |

D-6*37+1 |

D-6*37+1 |

D-6*37+1 |

D-6*37+1 |

D-6*37+1 |

D-6*37+1 |

D-6*37+1 |

||

|

I-beam track model (gb706-65) |

16~28b |

16~28b |

20a~32c |

20a~32c |

25a~63c |

25a~63c |

25a~63c |

||||

|

Minimum radius of circular track (m) |

1.5 |

1.5/2/3/4 |

2/2.5/3/4 |

2/2.5/3/4 |

2.5/3/4/5 |

2.5/3.5/6/7.5 |

2.5/3.5/6/7.5/9 |

||||

|

Lifting motor |

model |

BZD21-4 |

BZD21-4 |

BZD31-4 |

BZD32-4 |

BZD41-4 |

BZD51-4 |

BZD51-4 |

|||

|

capacity |

kw |

0.8 |

1.5 |

3 |

4.5 |

7.5 |

13 |

13-18.5 |

|||

|

speed |

RPM |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

|||

|

Power Supply |

v |

3-380 |

3-380 |

3-380 |

3-380 |

3-380 |

3-380 |

3-380 |

|||

|

Run the motor |

model |

BZDY11-4 |

BZDY11-4 |

BZDY12-4 |

BZDY12-4 |

BZDY21-4 |

BZDY21-4 |

BZDY21-4 |

|||

|

capacity |

kw |

0.2 |

0.2 |

0.4 |

0.4 |

0.8 |

0.8*2 |

0.8*2 |

|||

|

speed |

RPM |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

|||

|

|

Power Supply |

v |

3-380/660 |

3-380/660 |

3-380/660 |

3-380/660 |

3-380/660 |

3-380/660 |

3-380/660 |

||

There are two types of electrical equipments using in prescribed conditions will not cause an explosive burning environment:

|

Table 1 |

|||||||||||

|

T1 |

T2 |

T3 |

T4 |

T5 |

T6 |

||||||

|

450 ℃ |

300 ℃ |

200℃ |

135 ℃ |

100 ℃ |

85℃ |

||||||

|

Table 2 |

|||||||||||

|

temperature group |

T1 |

T2 |

T3 |

T4 |

T5 |

T6 |

|||||

|

class |

|||||||||||

|

Ⅱ A |

methane, toluene, methyl ester, ethane, propane, acetone, acrylic acid, benzene, styrene, carbon monoxide, acetic ether, acetic acid chlorobenzene, methyl acetate, ammonia |

methanol, ethanol, ethyl benzene, propanol, propylene, butanol, butane, butyl acetate, amyl acetate,cyclopentane |

Pentane, amyl alcohol, hexane, hexanol, heptane, octane, ring ethanol , turpentine, naphtha, petroleum, (including gasoline), fuel oil, amyl alcohol tetrachloro |

Acetaldehyde, trimethylamine |

|

ethyl nitrite |

|||||

|

Ⅱ B |

Propylene, dimethyl ether, town gas |

Butadiene, propylene oxide, ethylene |

Dimethyl ether, acrolein, and hydrocarbon |

diethyl etherethyl oxide |

|

|

|||||

|

Ⅱ C |

Hydrogen, water gas |

Acetylene |

|

carbon disulfide |

ethyl nitrate |

|

|||||

Yuantai Crane Factory has more than 30 years of manufacturing experience and is the top crane manufacturer and supplier in China.

Here, we can provide you with the best quality and the most competitive price.

we have over 30 years of experience engineering, manufacturing, and installing overhead crane systems.

Yuantai Crane can provide overall services for all types of industries cranes, and the main services are as follow:

|

Explosion proof crane Design Cranes designed by Yuantai Crane will solve any of your crane problems and material handling problems without spending any unnecessary expenditures. |

|

Explosion proof crane Installation EASAY installation, wonderful working performance. Yuantai Crane can provide on-site crane installation services and our crane engineers will be at your services when necessary. |

|

Lifetime Maintenance Jib crane maintenance from Yuantai Crane ensures your safety and working efficiency. |

|

Crane operator Training Yuantai Crane training includes jib crane operation, maintenance and inspection, and jib crane spare part supply, etc. |

|

Technical support The powerful technical support of Yuantai Crane will solve your jib crane technical problems. |

|

Crane parts Yuantai Jib crane parts will renew your cranes. |

Need Latest Crane Price? Please leave us the required Crane's Capacity, Lifting Height, Span, Travelling Length & Voltage for Quick Quotation.