We have compiled a comprehensive guide on how to choose a powered chain hoist, here are some key points:

Engineers and workers can choose an electric hoist that meets their lifting needs by considering factors like the rated capacity, working load limit, and duty cycles.

Rated Capacity-What weight will you be lifting, and what capacity is required?

The rated capacity of an electric chain hoist is the maximum weight it can support before buckling. It is determined by the motor's capacity, the rigidity of the electric hoist assembly, and the strength of the load chain or wire rope.

If you're looking for an electric hoist for your plant, the first thing you need to know is how much weight you'll be lifting. This is the first and most important requirement. Safety is an important consideration in your choice, and it is best to err on the side of caution when determining the safe working load of your hoist. For 'light' loads, standard adjustments in lifting machinery and chain hoists are 125kg, 250kg, 500kg, 1000kg, and 2000kg. So, for example, if your constant load is 500kg and you are likely to exceed that weight, don't risk it.Choose the 1000kg electric chain hoist to optimize your production while also ensuring the safety of your workers and cargo.

Working Load Limit

The maximum allowable weight that an electric chain hoist can safely carry is defined as the working load limit. It is calculated by multiplying the minimum breaking load by a safety factor. The factor of safety is determined by the hoist's construction, potential threats to workers, and the environment.

What is the height of lift?

The lift height of required for your lifting task is also an important consideration. Your proposed building is the most significant constraint in this regard. Don't assume that just because your building is a certain height, you'll be able to reach the same height in lift. Before making any decisions, determine the size of both your lifting structure and your chain hoist or electric wire rope hoist. If you are unsure about any terms, consult with a lifting professional. Errors at this stage of your progress can be very costly and can be avoided with a simple phone call.

Duty Cycle

Wear becomes more likely as the worker uses the hoist more frequently. The duty cycle of a hoist is the amount of time it can operate under normal conditions and parameters. For example, an electric hoist should only be used for one minute and then turned off for 99 minutes; thus, the duty cycle is 1/100 or 1%. Using a hoist outside of its duty cycle can accelerate wear and reduce service life.

Lifting and travel speeds have an impact on production and turnaround times. Here are a few details to consider when purchasing an electric hoist:

Lifting Speed -What lifting speed do you require?

Lifting speed refers to how quickly a load is lifted or lowered from its original position. An electric hoist can have a fixed or variable lifting speed that is controlled by the hoist controller. Slower speeds are used when the load is fragile, heavy, or requires precise positioning. Faster speeds are used in manufacturing and transportation. Loading and unloading of products are done at moderate speeds.

High speed and low speed

If high efficiency is your goal, you'll need a faster lifting speed to get the best return on investment on your chain hoist purchase. Consider a slower speed if all you're doing is sporadically shifting the delivered goods off the truck. Several factors influence hoist speed, including motor power, gearbox ratio, and chain reeving.

Single speed and dual speed

Another deciding factor in electric chain hoist selection is whether to go with single or dual speed operation. Single speed operation is the most common and used in normal lifting and lowering applications such as goods offloading. When more precise movements are required, dual speed hoists are ideal. Electric chain hoists have clear advantages over manual chain hoists (chain blocks); they are safer, faster, and far more convenient.

Travel Speed

The travel speed of a trolley refers to how quickly it traverses a specific distance to move the load. An electric chain hoist can have a fixed travel speed or an adjustable travel speed that is controlled by the hoist controller.

Voltage supply of electric chain hoists

An understanding of supply voltage is critical in choosing the right one. At yuantai Crane, we provide customized voltage design for your applications.

What voltage can we use? 110, 220 or 440? According to the type of electric hoist and capacity, the higher the capacity, the more likely you will require a higher voltage hoist. The higher the voltage, the lower the amps required, but it's critical to ask yourself wha you have available on site to ensure the product is running and working to its full potential. So you want to make sure that the motorized chain hoists you're using has a consistent electrical supply.

Yuantai Crane stocks a wide range of electric chain hoist models with capacities ranging from 1 to 35 tons, voltages ranging from 115V to 220V, 380V to 460V, and are intended for general material-handling operations. Prior to rental, each powered chain hoist is tested and certified to ensure maximum safety, efficiency, durability, and economy.

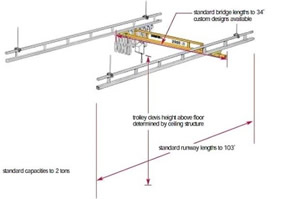

Beams

Beams make up the bridge on which the trolley is mounted and traverses. The bridge and its structural frame must be rigid and long-lasting enough to withstand the combined weight of the electric hoist and the object to be lifted. For the electric chain hoist to travel smoothly, the specifications and dimensions of the beam and the electric chain hoist trolley must be compatible. I-Beams, wide-flange beams, and patented track beams are the most common types of beams used in hoisting applications.

Take your future needs into consideration

While a 4-tonne electric chain hoist could be adequate to handle your products right now, what about your needs in the future? Do you expect to be able to lift things that are heavier than they are now in the future? Every time you needed to move heavier objects, it wouldn't be economical to upgrade. Make a wise choice and choose the electric hoist that can meet your needs now and in the future.CHAIN HOIST FACT

What kind of material will the electric chain hoist be lifting ?

Everyday objects that need to be moved from one location to another can be lifted with ease, but what if your load is a little unusual, like an asymmetrical load? What impact will it have on the specifications of your electric hoist and lifting machinery? Are there any risky environmental issues to take into account, too? Be as upfront and honest with your service provider as possible in this regard. Failure to communicate potential risks can waste productivity, money, and time, as well as endanger the safety of individuals using the lifting equipment.

How often will the electric chain hoist be in operation ?

You must ascertain how frequently the electric chain hoist will operate each day before purchasing . Also take into account the length of each cycle. Your elecric chain hoist's function must be prominently marked. The level of safety and effectiveness of your electric chain hoist will be determined by the ISO (International Organization for Standardization) or FEM (European Materials Handling Federation), which are recognized authorities in this respect.

What is your budget?

When purchasing an electrical chain hoist, a budget is always a consideration. Don't simply choose the cheapest option and hope for the best. In the event that something goes wrong, you must be confident that your service provider has extensive support in terms of expertise and spare parts. Ascertain that your supplier is the original equipment manufacturer or official distributor of a well-known product. Examine your supplier's facilities as thoroughly as possible to ensure that they can meet both your immediate and future needs.

Ensure you choose wisely and look for a long lasting warranty

Any reasonable electric chain hoist will come with a warranty to protect the buyer from any malfunctions or losses caused by manufacturer flaws. This term is usually one year, but it can vary. Obtain this warranty in writing from your electric chain hoist service provider, and as previously stated, ensure that the electric hoist supplier is capable of honoring the warranty through trained personnel and spares backup.