Jib cranes that stand alone are also referred to as pillar or floor-mounted jib cranes. All of these names relate to the same kind of crane, which is an independent crane that is not fixed to a building or other structure. It can be used both inside and outside to raise and move heavy loads.

The floor mounted freestanding jib crane, also known as new generation light lifting equipment, is designed and made with a reasonable structure, making it simple to install and use. The freestanding floor mounted freestanding jib crane is widely used for material lifting and moving on modern industrial production lines and assembly lines of machinery manufacturing, car, ship building, etc. This is due to its smart features, including energy saving, high efficiency, taking up less space, and large operating range. It is also used in warehouses, piers, laboratories, and other working places to lift and move various types of materials and goods. This jib crane is the perfect lifting tool for businesses looking to boost productivity and working circumstances.

Floor mounted freestanding Jib cranes are vital to any production process requiring speed, accuracy, and minimal downtime. They are adaptable, strong, and can be used for almost any type of workstation, supporting overhead cranes on production lines and ensuring the seamless operation of terminals, machining cells, and warehouses.The free standing workstation jib cranes, which are smaller and more maneuverable than overhead cranes, boost output through simple boom rotation and trolley movement, accelerating tasks and delivering a quick return on investment.

Specifications of freestanding jib cranes

The features of a freestanding jib crane are determined by the style of crane and the application for which it is used.A freestanding jib crane's lifting capacity can vary from 0.25 ton to 16 ton with different designs. The main specifications of standing freestanding jib cranes are as following for your reference. If a customized freestanding jib crane is required , please feel free to contact us.

- Lifting Capacity: 0.5t-20t

- Valid Radius: 3-15m

- Lifting Height: 3-8m

- Slewing Angle: 0-360°

- Lifting Speed: 0.33-8m/min

- Traveling Speed: 10/min

- Slewing Speed: 0.4-1r/min

- Work Duty: A3, A4

To ensure the safe operation of the freestanding cantilever crane when it is controlled and operated remotely, it is important to give attention to the following advice: not to simultaneously push the speed and motor switch buttons; not to stand underneath the crane's working arm while it is in operation; not to drag heavy objects; not to operate the speed and motor switch buttons simultaneously; The use of a floor mounted freestanding jib crane to lift or move dangerous goods, such as explosive or flammable materials, is prohibited. Overloading is also prohibited, and the crane cannot be used to lift or move goods without understanding their weights.

Types of freestanding jib cranes

Freestanding jib cranes based on foundation design

A freestanding jib crane is a jib system that does not have many placement constraints. Businesses can install this machinery indoors or outdoors, in an open area, or under other crane systems. However, freestanding jib crane requires a floor foundation.

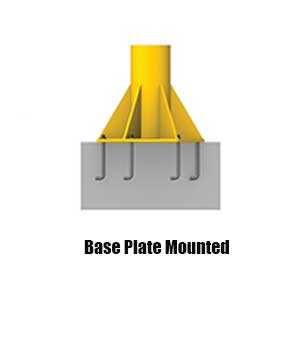

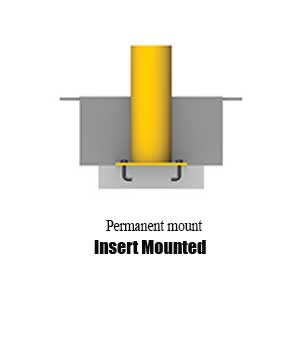

In terms of how they can be mounted and installed, there are three primary designs for freestanding jib cranes: base plate mounted, foundation mounted, and sleeve insert mounted.

Each design has its own set of foundation construction needs.A base plate mounted jib crane, for example, is secured by bolting a base plate to a reinforced concrete substructure and reinforcing the mast with gussets. A welded steel plate at the bottom of the mast of a foundation mounted jib crane is put on the first layer of concrete.A second pour of concrete strengthens the pole and eliminates the need for gussets.

The foundation requirements for free standing jib cranes vary from using existing concrete floors as thin as 6 inches to large foundations up to 5 feet deep and 11 feet square1.There are several techniques for leveling the base plate, including using shims and grout as needed to plumb the mast on an irregular concrete surface.

It is critical to ensure that the foundation for a freestanding jib crane is structurally sufficient to support the weight of the crane and its load. A welded steel plate at the bottom of the mast of a foundation mounted freestanding jib crane is put on the first layer of concrete.A second pour of concrete strengthens the pole and eliminates the need for gussets.During the planning process, it is critical to confer with a registered professional engineer to establish the foundation requirements based on your specific site.

Depending on the maker and model, the installation procedure for a freestanding cantilever jib crane may differ. The base-plate mounted form is a popular choice for freestanding jib cranes because it is simple to install.The pole is bolted to a reinforced concrete foundation and then reinforced with gussets .To guarantee correct jib crane installation, consult the manufacturer's installation manual or hire a professional.

Freestanding jib cranes types based on cantilever design

For freestanding jib cranes, there are various cantilever configurations. There are complete cantilever cranes and drop cantilever cranes, for example. Each style of crane has advantages and disadvantages.The full cantilever style provides the most lifting capability as well as the most clearance.

Full cantileve freetanding jib crane

Drop cantilever jib crane

Light duty & heavy duty freestanding jib cranes

A freestanding jib crane's working job refers to its ability to perform repetitive and unique lifting tasks within a smaller work cell area. Freestanding jib cranes are highly adaptable and can be combined with overhead bridge cranes to increase output.The boom of a freestanding jib crane can rotate 360° on both freestanding and mast type jib cranes. The operating range is circular, making it ideal for short-distance and densely discharged workplaces.

The lifting capability is the primary distinction between light duty and heavy duty freestanding jib cranes. The lifting capability of light duty freestanding jib cranes is lower than that of heavy duty freestanding jib cranes.Light duty freestanding jib cranes, for example, have capabilities of up to 2 tons, while heavy duty freestanding jib cranes have capacities of up to 15 tons.

lHeavy duty freestanding jib crane

light duty freestanding jib crane

Advantages of floor mounted freestanding jib crane

This kind of floor jib crane is equipped with hoist as its lifting mechanism, and the hoist can be electric wire rope hoist, electric chain hoist or European hoist as required. There are many advantages of crane shown as below:

- The cantilever jib crane is well-suited to short-distance, frequent, and intensive material lifting and moving activities, and it performs efficiently.

- The floor mounted freestanding jib crane has a very compact design, resulting in a light structure with outstanding performance.

- Yuantai floor jib crane is highly efficient, saves energy, is straightforward to operate, and requires minimal maintenance.

- With its stable brake, accurate location, and dependable working performance, the crane guarantees smooth and steady lifting and moving operations, quick positioning, and easier and safer loading.

- The foundation freestanding jib cranes can be designed and manufactured in various kinds based on the needs of the clients, and we can also customize the jib crane to meet specific requirements.

Applications of freestanding jib cranes

Freestanding jib crane can be used for a wide range of tasks. They can be used indoors for machining and assembly, where numerous jibs can be used in tandem for staged operations.They can also be used outside, for example, at marinas or cargo docks.Freestanding jib cranes can be used beneath large bridge crane systems or in open areas where individual work cells can be supported. They are versatile and can be used to lift and move heavy loads in a variety of sectors.

Manufacturing, warehousing, and building are just a few of the industries that use freestanding jib cranes. They can be used to lift and move heavy loads in places where other kinds of cranes cannot.

Floor mounted freestanding jib crane for indoor use

Outdoor floor-mounted freestanding jib crane

What is the difference between a freestanding jib crane and a wall-mounted jib crane?

The main difference between a freestanding jib crane and a wall-mounted jib crane is their range of rotation and placement constraints. There are several advantages to using a freestanding jib crane over a wall-mounted jib crane. Among these advantages are:

- Greater rotation: Because freestanding jib cranes can rotate 360 degrees, they have more range than wall-mounted jib cranes, which can only spin 180 degrees.

- Higher capacities:Freestanding Jib Cranes with capacities of up to 15 tons are offered.

- Greater spans: Depending on capacity, Freestanding Jib Cranes have greater spans than our wall-mounted jib cranes.

- Freestanding jib cranes have fewer placement restrictions and can be placed indoors or outdoors, in a confined space, or beneath other crane systems.

How to select jib cranes

It is critical to select a rotating cantilever jib crane with a lifting capacity appropriate for the weight of the load and to guarantee adequate clearance above the boom throughout its arc. It is also critical to select a reputable provider who has provided freestanding jib cranes for similar uses in the past.

Some of the most common questions and concerns for users of freestanding jib cranes include:

- What is the lifting capacity of the crane?

The lifting capacity of a freestanding jib crane can range from a few pounds up to several tons. It is important to choose a crane with a lifting capacity that is appropriate for the weight of the load.

- What is the height of the lift?

The height of the lift will depend on the intended use of the crane. The boom height can vary, with heights up to 40 feet being possible.

- What is the available space for the crane?

The available space for the crane will depend on the specific location where the crane will be used. It is important to ensure that there is sufficient clearance above the boom throughout its arc.

- How do I select the right type of crane for my needs?

When selecting a freestanding jib crane for a particular use, it is important to consider factors such as the weight of the load, the height of the lift, and the available space for the crane. It is also important to choose a reputable supplier with experience in providing freestanding jib cranes for similar applications.

- What are some common mistakes when selecting a freestanding jib crane?

Some common mistakes when selecting a freestanding jib crane include not considering the weight of the load, not considering the height of the lift, and not considering the available space for the crane.

- What are some safety considerations when using a freestanding jib crane?

Some safety considerations when using a freestanding jib crane include inspecting the crane before general use, looking for common warning signs such as the presence of debris on the runway, structural defects, missing or loosened bolts, and cracked welds. Additionally, you should check if the jib's arm slides smoothly. It is important to ensure that no one is allowed to walk under a loaded jib crane.

- How do I maintain a freestanding jib crane?

To maintain a freestanding jib crane, it is important to conduct regular preventive maintenance and inspections. During inspections, you should look for common warning signs such as the presence of debris on the runway, structural defects, missing or loosened bolts, and cracked welds. Additionally, you should check if the jib's arm slides smoothly.

What affect the cost of freestanding jib crane?

The cost of a freestanding jib crane can vary depending on several factors, including the manufacturer, model, capacity, and any additional features or customizations. It is recommended to contact a manufacturer or supplier for a specific quote based on your needs.

Besides the price of the freestanding jib crane itself, there are several other factors that can affect the overall cost. These include:

- Installation: The cost of installing a freestanding jib crane can vary depending on factors such as the complexity of the installation and the need for any additional equipment or materials.

- Shipping: The cost of shipping the freestanding jib crane to your location can also add to the overall cost.

- Maintenance: Regular maintenance is necessary to ensure the safe and efficient operation of a freestanding jib crane. The cost of maintenance can vary depending on factors such as the frequency of maintenance and the need for any replacement parts.

How to buy a freestanding jib crane at cost-effective price ?

When selecting a freestanding jib crane for a particular use, it is important to consider factors such as the weight of the load, the height of the lift, and the available space for the crane. It is also important to choose a reputable supplier with experience in providing freestanding jib cranes for similar applications

To buy a freestanding jib crane at a cost-effective price, you can consider the following tips:

- Research and compare prices from different suppliers to find the best deal.

- Consider purchasing a used or refurbished crane if it meets your needs and is in good condition.

- Look for promotions or discounts offered by suppliers.

- Consider the total cost of ownership, including installation, maintenance, and operating costs, when comparing prices.

- Work with a reputable supplier who can provide you with a high-quality crane at a fair price.

When selecting a freestanding jib crane manufacturer, it’s better to select a manufacturer who is certified. The jib crane manufacturing certificates and other related testing certificates should be provided. Jib crane price is also one of the decisive factors. That’s to say, the jib crane should be selected based on the consideration on your budget, the lifting capacity of jib crane, jib crane application environment, i.e, the conditions of your factory or workshop, serving life, etc.

Full cantileve freetanding jib crane

Full cantileve freetanding jib crane Drop cantilever jib crane

Drop cantilever jib crane  lHeavy duty freestanding jib crane

lHeavy duty freestanding jib crane  light duty freestanding jib crane

light duty freestanding jib crane  Floor mounted freestanding jib crane for indoor use

Floor mounted freestanding jib crane for indoor use Outdoor floor-mounted freestanding jib crane

Outdoor floor-mounted freestanding jib crane