Auxiliary Hoist Overhead Cranes for sale. Custom Double Girder Overhead Crane with Main Hoists & Auxiliary Hoists for heavy duty material handling up 5 to 80 ton

Auxiliary Hoist Overhead Cranes, Double Girder Overhead Crane with Main & Auxiliary Hoists

Auxiliary Hoist Overhead Cranes stand at the forefront of industrial lifting, redefining the landscape with a fusion of power and precision. In this journey, we unveil the essentials that make these cranes indispensable and explore the seamless fusion of raw power and meticulous precision that sets them apart.

Essentials of Auxiliary Hoist Overhead Cranes: Unveiling the Core Functionality and Significance

At the heart of every Auxiliary Hoist Overhead Crane lies a sophisticated mechanism designed to lift operations to new heights. These cranes feature an auxiliary hoist, a powerhouse that complements the main hoist, amplifying lifting capabilities. The intricacies of cable systems, drums, and motors harmonize to create a symphony of strength, making these cranes ideal for handling heavy loads with precision.

The significance of Auxiliary Hoist Overhead Cranes extends beyond mere lifting; it's about control. Whether delicately handling materials in manufacturing or tackling the robust demands of construction projects, these cranes adapt to diverse scenarios with finesse. They optimize lifting operations, making the seemingly impossible, possible.

The Fusion of Power and Precision: How Auxiliary Hoist Overhead Cranes Redefine Lifting Capabilities

Imagine a lifting solution that seamlessly combines raw power with surgical precision. That's the essence of Auxiliary Hoist Overhead Cranes. By integrating auxiliary hoists into overhead crane systems, the lifting capabilities are not just increased; they are redefined. The fusion of power and precision creates a lifting experience that goes beyond the ordinary.

These cranes excel in handling heavier loads with efficiency and versatility. The auxiliary hoist, working in harmony with the main hoist, transforms lifting operations into a synchronized dance, ensuring materials are positioned with accuracy. The result is not just lifting; it's a performance where power meets precision.

As we embark on this exploration, the spotlight will shift to the types of Auxiliary Hoist Overhead Cranes, each offering tailored solutions for specific lifting needs. Stay tuned to discover the marvels of Single Girder and Double Girder cranes, each with its unique features and applications. The journey with Auxiliary Hoist Overhead Cranes has just begun, promising to elevate lifting solutions to new dimensions.

Types of Auxiliary Hoist Overhead Cranes

Tailored Solutions for Every Task

As we delve deeper into the realm of Auxiliary Hoist Overhead Cranes, the stage is set to explore the distinct types that bring tailored solutions for various lifting tasks. Let's unravel the marvels of Single Girder and Double Girder cranes, each with its unique benefits and versatile applications.

There are several main types of Auxiliary Hoist Overhead Cranes, each with its unique design features and typical applications. Here are some of the main types:

Economical Auxiliary Hoist

Economical Auxiliary Hoist Crane

CD/MD Main and Auxiliary Hoist Crane:

Design Features:

CD (single speed) or MD (dual speed) hoists for main lifting operations.

Auxiliary hoist for additional lifting tasks.

Typical Applications:

Commonly used in general industrial settings.

Suitable for tasks requiring both main and auxiliary lifting operations.

Low Headroom Auxiliary Hoist

Low Headroom Auxiliary Hoist Crane

Low Headroom Main and Auxiliary Hoist Crane:

Design Features:

Specifically designed for applications with limited headroom.

Compact design with a reduced distance between the beam and the hook.

Utilizes low headroom trolleys for efficient use of vertical space.

Typical Applications:

Ideal for facilities with limited space or low ceiling clearance.

Commonly used in workshops, warehouses, and manufacturing plants.

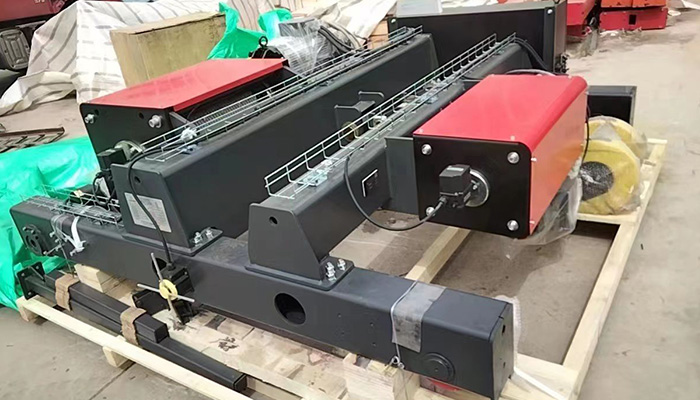

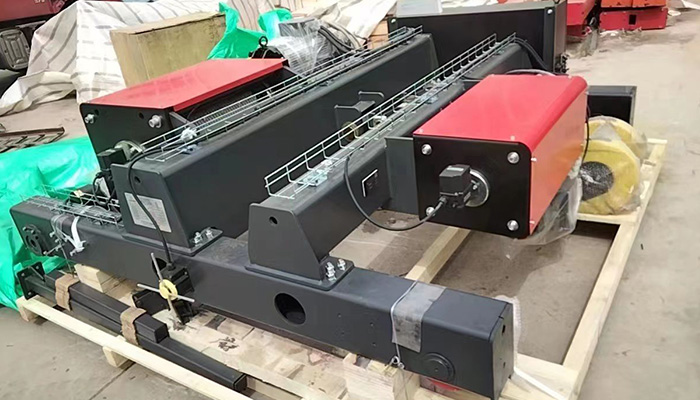

Builtup Auxiliary Hoist

Builtup Auxiliary Hoist Crane

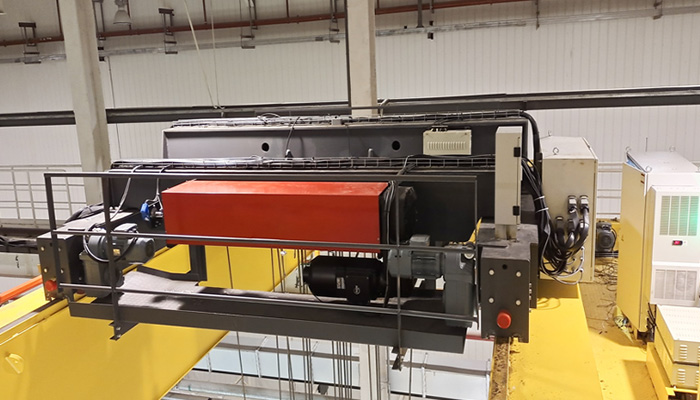

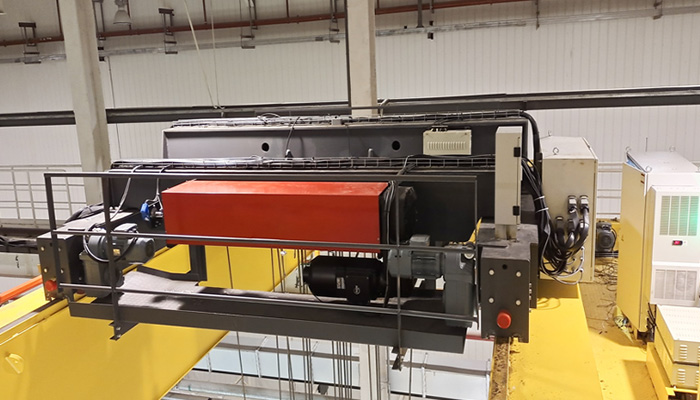

Built-Up Hoist Winch Crane:

Design Features:

Features a built-up hoist system for heavy-duty lifting tasks.

Sturdy construction with high load-bearing capacity.

Typical Applications:

Well-suited for heavy industrial applications such as steel manufacturing and shipbuilding.

Used in scenarios where substantial loads need to be lifted with precision.

Each type of Auxiliary Hoist Overhead Crane is designed to cater to specific industrial needs, offering tailored solutions for lifting operations. The choice of crane depends on factors such as available space, load requirements, and the nature of the lifting tasks in a particular industrial setting.

Features, Benefits, and Typical Applications of Auxiliary Hoist Overhead Cranes

Auxiliary Hoist Overhead Cranes are versatile lifting solutions designed to enhance efficiency, provide precise lifting capabilities, and adapt to diverse industrial applications. Here are the key features, benefits, and typical applications of these cranes:

Features:

Main and Auxiliary Hoist Systems:

Versatile Lifting Operations:

The integration of both main and auxiliary hoist systems provides versatility in lifting operations.

Main hoist handles primary lifting tasks, while the auxiliary hoist offers additional lifting capabilities, enhancing overall operational flexibility.

Single and Dual Speed Options:

Customizable Lifting Speeds:

Available in single-speed (CD) or dual-speed (MD) configurations, catering to specific lifting speed requirements.

Single-speed for regular lifting tasks, while dual-speed allows for precision in delicate operations and efficiency in heavier lifts.

Low Headroom Design:

Vertical Space Optimization:

Specifically designed models feature a low headroom design, optimizing vertical space in facilities with limited clearance.

Ideal for applications where maximizing overhead space is crucial, allowing for efficient use of available vertical space.

Built-Up Hoist System:

Heavy-Duty Lifting Capability:

Incorporates a built-up hoist winch system, designed for heavy-duty lifting tasks with a high load-bearing capacity.

Suitable for applications requiring the precise and efficient handling of substantial loads in industries like manufacturing and construction.

Advanced Safety Features:

Ensuring a Safe Working Environment:

Emergency stop systems provide swift response mechanisms in unforeseen emergencies, prioritizing safety.

Load-limiting devices prevent overloading, ensuring that loads are lifted within safe and designated limits.

Collision avoidance systems with advanced sensors prevent collisions, maintaining a secure working environment for operators and equipment.

Compact and Sturdy Construction:

Space-Efficient and Durable:

Compact designs make these cranes suitable for various space constraints in industrial settings.

Sturdy construction ensures durability and reliability, with the ability to withstand the demands of regular and heavy-duty lifting operations.

Adaptable Trolleys:

Efficient Load Movement:

Trolleys are designed for efficient movement of loads along the crane's runway.

Some models feature trolleys specifically designed for low headroom applications, ensuring adaptability to various lifting scenarios.

These features collectively contribute to the efficiency, safety, and adaptability of Auxiliary Hoist Overhead Cranes, making them indispensable tools for a wide range of industrial lifting operations.

Benefits:

Enhanced Lifting Capabilities:

Flexibility in Load Handling:

The integration of both main and auxiliary hoist systems provides a dynamic lifting solution.

Enables the handling of different loads with enhanced capabilities, offering flexibility in various industrial scenarios.

Efficiency and Productivity:

Dual-Speed Options:

Dual-speed configurations (MD) cater to varying operational needs.

The availability of different lifting speeds allows for precise control in delicate operations and efficient performance in heavier lifts, contributing to overall operational efficiency and boosted productivity.

Versatility in Applications:

Adaptability to Various Industries:

Suited for a broad spectrum of industrial applications, ranging from routine lifting tasks to heavy-duty operations.

Finds applications in manufacturing, construction, warehouses, and other industrial settings, showcasing versatility in addressing diverse lifting needs.

Space Optimization:

Ideal for Limited Ceiling Clearance:

Low headroom designs are tailored for facilities with limited ceiling clearance.

Optimizes vertical space utilization, making these cranes ideal for environments where maximizing overhead space is crucial.

Precise and Controlled Movements:

Ensuring Accuracy in Operations:

Advanced safety features, such as emergency stop systems and collision avoidance systems, contribute to precise and controlled movements.

Operators can execute lifting tasks with accuracy, ensuring the safety of both the equipment and the surrounding environment.

Cost-Efficient Performance:

Optimal Performance Without Compromise:

Models with built-up hoist systems offer cost-efficient performance for heavy-duty lifting tasks.

The combination of high load-bearing capacity and efficiency ensures that these cranes provide optimal performance without compromising on quality, resulting in a cost-effective solution for heavy-duty lifting operations.

These benefits collectively make Auxiliary Hoist Overhead Cranes valuable assets in industrial settings, addressing a variety of lifting requirements while enhancing efficiency, safety, and overall operational performance.

Typical Applications:

Manufacturing Plants:

Material Handling in Production:

Auxiliary Hoist Overhead Cranes play a crucial role in manufacturing plants for lifting and moving materials during the production process.

Optimizes efficiency by facilitating the seamless transfer of materials within the manufacturing facility, ensuring a streamlined production workflow.

Warehousing and Logistics:

Precision in Goods Movement:

Ideal for warehouse operations where precision in the movement of goods is paramount.

Enables efficient loading and unloading of inventory, organizing goods with accuracy, and maximizing storage space within the warehouse.

Construction Projects:

Lifting Heavy Materials and Components:

Applied in construction projects for lifting and positioning heavy materials and components.

Contributes to the efficiency of construction tasks by handling substantial loads with precision, ensuring the timely completion of projects.

Steel Manufacturing:

Handling Substantial Loads:

Built-up hoist winch cranes find common employment in steel manufacturing due to their ability to handle substantial loads.

Used for lifting and transporting heavy steel materials within manufacturing facilities, contributing to the production processes in the steel industry.

Shipbuilding:

Precise Positioning of Ship Components:

Integral in shipbuilding processes for the precise positioning of heavy ship components.

The adaptability and lifting capabilities of these cranes ensure the accurate placement of ship parts, contributing to the construction of vessels with precision.

Workshops and Maintenance Facilities:

Reliable Lifting Solution for Various Tasks:

Suited for workshops and maintenance facilities, offering a reliable lifting solution for a variety of tasks.

Whether it's lifting machinery during maintenance or handling materials in a workshop setting, these cranes provide the flexibility needed in diverse industrial applications.

Auxiliary Hoist Overhead Cranes, with their diverse features and benefits, prove to be indispensable tools across a range of industries. From optimizing manufacturing efficiency to facilitating precise movements in logistics and construction, these cranes play a pivotal role in enhancing lifting operations and contributing to the overall productivity of modern industries.

User Concerns and Solutions

As we navigate the realm of Auxiliary Hoist Overhead Cranes, it's crucial to address the concerns that users may have. Operational efficiency and safety are paramount considerations in any industrial setting. Let's explore how these concerns are effectively addressed, ensuring a seamless and secure lifting experience.

Operational Efficiency Challenges: Tailored Efficiency of Single and Double Girder Cranes

a. Challenge: Overcoming Challenges in Operational Efficiency

Operational efficiency is a key concern for users seeking to integrate Auxiliary Hoist Overhead Cranes into their workflow. The challenge lies in ensuring that lifting operations are not just effective but also streamlined for maximum productivity.

b. Solution: The Tailored Efficiency of Single and Double Girder Auxiliary Hoist Overhead Cranes

The efficiency of lifting operations is intricately linked to the design and capabilities of the cranes in use. Single Girder Marvels, with their simplicity and adaptability, provide cost-efficient performance without unnecessary complexities. They are tailored for applications where precision and adaptability are paramount, addressing the challenge of operational efficiency.

Double Girder Dominance, on the other hand, tackles operational challenges in heavy-duty tasks. The structural prowess and enhanced stability make them ideal for scenarios where substantial loads demand efficient handling. These cranes are designed to optimize efficiency in challenging environments, ensuring consistent performance.

Safety Prioritization: Advanced Safety Features Embedded in Auxiliary Hoist Overhead Cranes

a. Challenge: Ensuring a Safe Working Environment

Safety is a non-negotiable aspect of industrial operations. The challenge is to create a working environment where lifting tasks are executed with the utmost safety, protecting both operators and the surrounding infrastructure.

b. Solution: Advanced Safety Features Embedded in Auxiliary Hoist Overhead Cranes

Auxiliary Hoist Overhead Cranes prioritize safety through advanced features embedded in their design. Both Single Girder Marvels and Double Girder Dominance come equipped with emergency stop systems, load-limiting devices, and collision avoidance systems.

Advanced Safety Features:

Emergency Stop Systems: Swift response mechanisms to address unforeseen emergencies.

Load-Limiting Devices: Ensuring that loads are lifted within safe and designated limits.

Collision Avoidance Systems: Advanced sensors preventing collisions, maintaining a safe working environment.

By integrating these safety features, these cranes not only address the challenge of ensuring a safe working environment but also elevate safety standards in industrial lifting operations. The commitment to safety is woven into the very fabric of Auxiliary Hoist Overhead Cranes, providing users with the confidence to navigate operational challenges securely.

As we delve into the safety measures incorporated into these cranes, the exploration of compliance with industry standards and maintenance protocols awaits. Join us on the next leg of the journey, where we ensure that the use of Auxiliary Hoist Overhead Cranes aligns with the highest industry standards and practices.

Questions and Answers on Auxiliary Hoist Overhead Cranes

Curiosity leads us to delve into the intricacies of Auxiliary Hoist Overhead Cranes. Here are answers to some of the burning questions you might have about how these cranes balance simplicity with high performance, their structural robustness, their impact on warehouse operations, safety considerations, and the advantages offered in heavy industrial applications.

How do Single Girder Auxiliary Hoist Overhead Cranes balance simplicity with high performance?

Answer:

Single Girder Auxiliary Hoist Overhead Cranes achieve a delicate balance by focusing on simplicity without compromising on performance. The streamlined design eliminates unnecessary complexities, allowing for efficient lifting operations. The adaptability of Single Girder Cranes ensures high-performance levels without sacrificing cost-effectiveness, making them ideal for various industrial applications.

What structural features define the robustness of Double Girder Auxiliary Hoist Overhead Cranes?

Answer:

The robustness of Double Girder Auxiliary Hoist Overhead Cranes stems from their structural features. The double girder design provides enhanced stability, crucial for heavy-duty lifting scenarios. This design allows for a higher load-bearing capacity, making them well-suited for applications where substantial loads need to be handled with efficiency. The structural prowess ensures durability and consistent performance in challenging industrial environments.

In what ways do Auxiliary Hoist Overhead Cranes optimize warehouse operations?

Answer:

Auxiliary Hoist Overhead Cranes play a transformative role in optimizing warehouse operations. Single Girder Marvels excel in efficiently handling materials within warehouses, ensuring precise and timely material movements. Their adaptability makes them ideal for tasks such as loading and unloading pallets or rearranging inventory. The streamlined design and versatility enhance warehouse efficiency by maximizing storage capacity without compromising accessibility.

How are safety concerns addressed in the design of these cranes?

Answer:

Safety is a top priority in the design of Auxiliary Hoist Overhead Cranes. Both Single Girder Marvels and Double Girder Dominance are equipped with advanced safety features. These include emergency stop systems for swift response in unforeseen emergencies, load-limiting devices to ensure safe lifting, and collision avoidance systems with sensors preventing collisions. The integration of these safety measures creates a secure working environment, prioritizing the well-being of operators and the surrounding infrastructure.

What advantages do Double Girder Cranes offer in heavy industrial applications?

Answer:

Double Girder Auxiliary Hoist Overhead Cranes offer distinct advantages in heavy industrial applications. Their structural design provides enhanced stability, crucial for heavy-duty lifting scenarios. The higher load-bearing capacity allows them to efficiently handle substantial loads, making them ideal for heavy industries such as steel manufacturing and shipbuilding. The durability and versatility of Double Girder Cranes contribute to their efficiency in demanding industrial environments.

As we uncover the answers to these questions, the journey through the world of Auxiliary Hoist Overhead Cranes continues. The final segment awaits, where we recap the key points, reiterate the significance in industrial operations, and explore the future outlook for these transformative lifting solutions. Stay tuned for the concluding chapter of our exploration.

As we conclude our exploration of Auxiliary Hoist Overhead Cranes, it's time to reflect on the journey through the realms of efficiency, structural prowess, tailored solutions, and answers to your burning questions. Let's recap the key points that define your journey with these transformative lifting solutions.

Economical Auxiliary Hoist

Economical Auxiliary Hoist Economical Auxiliary Hoist Crane

Economical Auxiliary Hoist Crane Low Headroom Auxiliary Hoist

Low Headroom Auxiliary Hoist Low Headroom Auxiliary Hoist Crane

Low Headroom Auxiliary Hoist Crane Builtup Auxiliary Hoist

Builtup Auxiliary Hoist Builtup Auxiliary Hoist Crane

Builtup Auxiliary Hoist Crane