Single Girder Gantry Crane

Double Girder Gantry Crane

Portable Gantry Crane

Rubber Tyred Crane

Tonnages & Specifications

Uses & Applications

Philippines

Pakistan

Saudi Arabia

Bangladesh

UAE

Bahrain

Morocco

Australia

Malaysia

Indonesia

Singapore

Thailand

Crane for Sale Qatar

Overhead Crane Nigeria

Crane Uzbekistan

Algeria

Kenya

Crane for Sale Zambia

Cranes & Hoist for Sale Uganda

South Africa

Ghana

Congo

Vietnam

Serbia

Kazakhstan

Bolivia

Russia

Brazil

Jordan

Egypt

UK

Oman

Spain

Jamaica

Guinea

Dominica

Laos

Portugal

Kuwait

Ethiopia

Mongolia

Azerbaijan

Trinidad and Tobago

Poland

Fixed Monorail Hoist

Fixed Monorail Hoist Straight Monoral Crane

Straight Monoral Crane European Type Hoist

European Type Hoist Annular Monorail Crane

Annular Monorail Crane S Type Monorail Crane

S Type Monorail Crane Freestanding monorails

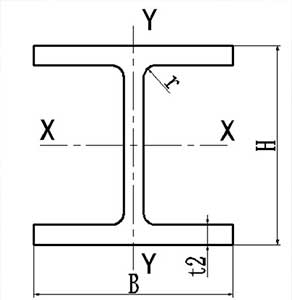

Freestanding monorails H beam

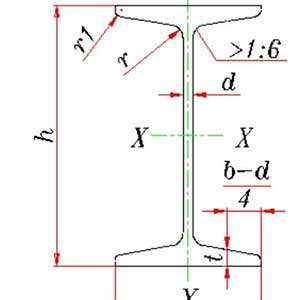

H beam I beam

I beam