Explosion Proof Wire Rope Hoists 1 to 20 Ton for Single Girder Cranes, 3 to 18 Ton for Double Girder Cranes. Custom explosion proof electric hoist for sale.

Explosion Proof Wire Rope Hoists 1-80 Ton for Hazardous Workshops

European style explosion-proof wire rope hoists are specialized lifting devices designed for hazardous environments where there is a risk of explosion due to the presence of flammable gases, vapors, dust, or combustible materials. These hoists adhere to strict safety standards and regulations to prevent ignition sources that could trigger an explosion.

Features of Explosion Proof Electric Hoists

Key features of European style explosion-proof wire rope hoists may include:

- Explosion-proof construction: These hoists are constructed using materials and designs that minimize the risk of sparks or heat generation. They often have enclosed motors, flameproof enclosures, and spark-resistant components.

- Certifications and compliance: They adhere to stringent European Union (EU) safety standards and may comply with ATEX directives (ATmosphères EXplosibles) which define the requirements for equipment used in potentially explosive atmospheres.

- Specialized controls: These hoists are equipped with specialized controls that prevent sparking or overheating. They may include explosion-proof pendant control stations or remote controls.

- Robust build: Designed for durability and reliability in demanding environments, they often feature sturdy and corrosion-resistant materials.

- Safety mechanisms: Built-in safety features such as overload protection, emergency braking systems, and limit switches ensure safe operations.

- Customizable options: These hoists can often be customized to suit specific application requirements, including varying lifting capacities, speeds, and mounting options.

- Usage in hazardous environments: They are suitable for use in industries such as oil and gas, chemical processing, pharmaceuticals, mining, and other settings where explosive atmospheres pose a risk.

It's important to consult with experts or professionals familiar with the specific safety requirements and regulations in your region or industry to ensure the appropriate selection, installation, and usage of explosion-proof wire rope hoists.

Application of Explosion Proof Electric Hoists

- National Standards Compliance: The explosion-proof electric hoist complies with national standards such as JB/T 10222, GB3831, and GB383 These standards outline the general requirements for equipment in explosive environments and the specifications for equipment protected by flameproof enclosure "d."

- Work Level and Working Environment: The hoist has a work level of M5, indicating its suitability for heavy-duty operations. The specified working environment temperature for the crane is between -20 ℃ to +40 ℃, ensuring its functionality within this temperature range.

- Suitability for Explosive Gas Environments: This hoist is designed to operate in environments where explosive gases might be present. It's suitable for areas where the explosion-proof level is not higher than level B or C, or where the environment is formed by combustible gas, steam, and air, with an ignition temperature group not lower than T4 (135 ℃). This ensures that the hoist is safe to use in environments where there's a risk of explosion due to the presence of certain gases.

- Applicable Hazardous Areas: The hoist is suitable for use in Zone 1 or Zone 2 hazardous areas. Zone 1 refers to an area where an explosive atmosphere is likely to occur occasionally during normal operation, while Zone 2 is where an explosive atmosphere is not likely to occur frequently and, if it does, it will exist for a short period.

- Exclusion from Zone 0: Zone 0 refers to an area where an explosive atmosphere is present continuously or for long periods. This particular hoist is not designed for use in Zone 0 environments.

Overall, this detailed description highlights the precise conditions and environments in which the explosion-proof electric hoist can be safely and effectively used, ensuring compliance with specific national standards and safety regulations related to explosive atmospheres.

Note:

- Zone 0: A site that explosive gas mixture appears continuously, frequently for a short time or exists for a long time under normal conditions.

- Zone 1: A site that explosive gas mixture possibly occur under normal conditions.

- Zone 2: A site that explosive gas mixture can not appear under normal conditions but equipment failure or mis-operation may occur occasionally and shortly.

See the following table for examples of hazardous gases applicable to the crane. For the other hazardous gases not listed in the table, see the appendix of GB383

|

Explosion-proof mark(Category,level) |

Hazardous gas |

|

ExdⅡBT4 |

Ethane, propane, butane, heptane, decane, ethylene, propylene, carbon monoxide, gasoline, acetone, styrene, toluene, benzene, methanol, ethanol, vinyl chloride, acetaldehyde, diethyl ether |

|

ExdⅡCT4 |

Hydrogen, water gas, acetylene and gases other than ExdⅡCT4 |

Ignition group

|

Temperate group |

Allowable maximum surface temperature (º C) |

|

T1

T2

T3

T4

T5

T6 |

450

300

200

135

100

85 |

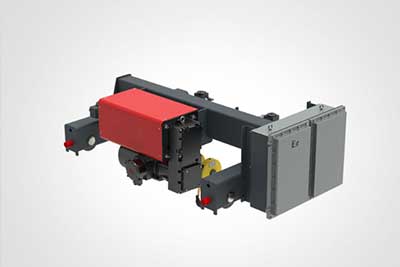

explosion-proof electric hoist is equipped with original spatial rod support structure and hoisting device is arranged in the classic "C" type structure. The hoisting drive device drives the large-diameter drum group and the coaxial three-in-one drive device simultaneously drives the wheel groups on both sides. The rope wedge device and the pulley group are suspended on the support rod, in which the high-strength nylon pulley group and the hook group are used.

![Explosion proof wire rope electric hoist 40 ton project for your reference]()

Explosion proof wire rope electric hoist 40 ton project for your reference

Advantages of Explosion-Proof Wire Rope Hoists:

Independent Core Technology: Collaborating with key universities and research institutions, these hoists develop core parts independently, ensuring controlled product quality and timely delivery. The motor, an explosion-proof three-phase induction motor with variable frequency electromagnetic braking, guarantees stable speed, substantial overload capacity, and high mechanical strength, ideal for intermittent operations with frequent hoisting and braking. Motor features include a standard insulation grade of F and IP65 protection.

Modular Design: Featuring a modular design, these hoists offer versatility. Four hoisting drives and two running drives can match various electric hoists ranging from 1-20t, adaptable to different structures like standard headroom, low headroom, crab running, and fixed type modes.

Compact Structure and Size Limit: Utilizing large-diameter drums across all series increases hoisting height and minimizes lateral limits, resulting in a smaller working blind area for cranes and providing users with more functional space.

Maintenance-Free, Energy-Efficient, and Eco-Friendly: Various design aspects contribute to these benefits:

- a. Reducers with high-precision hardened face gears come pre-filled with top-quality lubricating oil, requiring no replacement within the product's lifecycle.

- b. Employing maintenance-free steel ropes from renowned brands.

- c. Upgrading vulnerable parts to durable ones, like high-strength nylon fairleads.

- d. Electromagnetic disc brakes with automatic brake clearance compensation and no maintenance needs.

- e. Reduced motor power by 30% compared to traditional electric hoists, achieving over 20% increased work efficiency through frequency conversion positioning technology.

- f. Entire machine noise levels below 70 dB, promoting a quieter work environment.

- g. Brake pads designed without asbestos, ensuring safety.

- h. Components, such as nylon fairleads and steel ropes, prevent the generation of metal dust, ensuring a clean operation space for workers.

Intelligent and Remote Maintenance Design: Incorporating smart features for enhanced functionality and convenience:

- a. Security monitoring systems for added safety.

- b. Big data management and cloud platform connectivity for comprehensive data handling.

- c. Real-time monitoring facilitated through a mobile app for ease of access and remote maintenance.

Explosion-proof electric hoist for single girder crane

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Low headroom explosion-proof electric wire rope hoist for single girder crane

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Explosion-proof wire rope hoist for double girder cranes

Lifting capacity: 3t~80 Ton, Customized up to 200 Ton

Lifting height: 6m~30m

Work level: M3~M5

Intelligent Functions of Explosion-Proof Electric Hoists:

- Precision Inching Movement: Ensures meticulous and gradual crane movements as it nears its destination. This feature can be precisely applied to the hoisting mechanism, trolley, and crab, allowing customizable inching movement settings.

- Dead Slow Control: Maintains control system stability, enabling deliberate, precise movements during crane operations and loading. Applicable to the hoisting mechanism, trolley, and crab for deliberate and meticulous movements.

- Zero Speed Hover: Automatically initiates to prevent slip hook occurrences when the control system detects a trend toward slip hooking (motor non-rotation despite brake release).

- Impact-Proof Features: Equipped with upper pre-limit, upper limit, and top impact-proof functions, meeting diverse customer needs for ensuring crane safety during operations.

- Electric Anti-Sway Capability: Automatically restricts loader sway during handling, ensuring faster and more accurate positioning, enhancing stability throughout the handling process.

- Regional Load Limiting: Implements hazardous area restriction functions, minimizing risky situations during loader movements and safeguarding against damage to the loader, crane, and surrounding facilities.

- Speed Expansion Capability: Offers practical and efficient regulation by introducing sub-low speed and sub-high speed functions, in addition to standard low and high-speed settings, enhancing operational versatility.

- Multi-Hook Coordination: Monitors and controls the position variance of multiple hooks, ensuring synchronized movement at uniform speeds, thereby enhancing crane efficiency and performance.

- Multi-Trolley Synchronization: Monitors and controls the positional differences of multiple cranes operating simultaneously, ensuring synchronized operation at uniform speeds for enhanced efficiency.

- Wireless Integration: Optional wireless module integration allows connectivity to the Crane Industrial Internet Platform, enabling comprehensive crane life cycle management.

![Application of explosion proof electric hoist on the double girder explosion proof overhead crane with European style design]()

Application of explosion proof electric hoist on the double girder explosion proof overhead crane with European style design

Applications of Explosion Proof Electric Hoists

Explosion-proof wire rope hoists find application across various industries and environments where the presence of potentially combustible gases, vapors, or dust requires specialized equipment to ensure safety. Some key applications include:

- Oil and Gas Industry: In oil refineries, drilling rigs, petrochemical plants, and gas processing facilities, where the presence of flammable gases or vapors necessitates explosion-proof equipment. These hoists aid in lifting heavy equipment and materials in hazardous areas.

- Chemical Industry: Chemical manufacturing plants and storage facilities dealing with volatile substances utilize explosion-proof hoists for safe material handling, minimizing the risk of ignition due to sparking or overheating.

- Mining Operations: Mines often have environments containing combustible gases or dust. Explosion-proof hoists are crucial for lifting, transporting, and installing heavy machinery, equipment, or materials in these settings.

- Pharmaceutical Industry: Laboratories and manufacturing facilities handling flammable or hazardous substances require explosion-proof hoists to safely move equipment or materials without the risk of igniting volatile compounds.

- Food Processing Industry: Particularly in areas where there's a potential for the accumulation of dust or flammable particles, explosion-proof hoists ensure safe lifting and movement of materials in food processing and grain-handling facilities.

- Automotive Manufacturing: Areas in automotive plants where there's exposure to solvents, paints, or other flammable materials utilize explosion-proof hoists to ensure safe handling during assembly or material transport.

- Aerospace Industry: Facilities dealing with sensitive aerospace materials or chemicals may employ explosion-proof hoists for lifting and transporting critical components without risking ignition.

- Utilities and Power Plants: Power generation facilities dealing with combustible gases or substances utilize these hoists for maintenance, installations, and repairs within hazardous zones.

- Waste Management and Recycling: Environments where there's a potential presence of combustible materials, gases, or dust, such as recycling plants or waste treatment facilities, utilize explosion-proof hoists for safe material handling.

- Shipbuilding and Ports: Shipyard facilities and port areas dealing with flammable substances utilize explosion-proof hoists for lifting heavy loads and equipment safely in potentially hazardous marine environments.

In essence, these hoists are indispensable in environments where the risk of explosion due to the presence of flammable substances or combustible atmospheres is a concern. Their application ensures not only safety but also efficiency in material handling operations within such sensitive settings. If you have any need of explosion proof electric hoist, please feel free to contact us by leaving a message downbelow.