Crane Selection for Military Facilities: Key Defense Operation Factors

Explore essential crane selection factors—capacity, durability, mobility, compliance, and support—for reliable performance in demanding military environments.

Introduction

Overview of Crane Importance in Military Operations

Cranes play a quiet but critical role in military environments. They’re used behind the scenes — but the impact is huge.

In defense facilities, cranes support everything from routine equipment transfers to emergency response setups. They help move tanks, engines, shelters, missile containers, and even radar systems.

They’re not just about lifting heavy items. Cranes also contribute to:

- Secure and precise handling of sensitive gear

- Quick deployment during field operations

- Maintenance and assembly of large-scale military hardware

- Safe logistics in armories, airbases, and naval docks

In short, cranes help keep operations organized, efficient, and safe — even under pressure.

Purpose of the Guide

This guide is for military engineers, procurement officers, and anyone responsible for handling equipment in defense facilities.

It’s not just about picking a strong crane. It’s about choosing one that works reliably in extreme conditions — dust, heat, salt air, or low visibility — and still gets the job done.

Here’s what this guide aims to do:

- Highlight practical crane features that matter in defense settings

- Help you think beyond just lifting capacity — such as mobility, control systems, and compliance

- Give you a clear idea of what questions to ask when choosing a crane for military use

At the end of the day, the goal is simple: make sure the crane supports the mission, not slows it down.

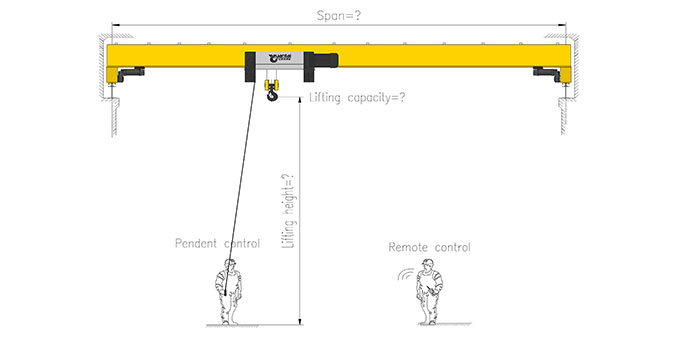

single girder overhead crane main specification for quotation

Key Considerations for Crane Selection in Military Facilities

Load Capacity

Getting the right lifting capacity is one of the first decisions to make. Military operations deal with a wide range of loads — from compact gear crates to massive armored vehicles.

Too small, and the crane can’t do the jo Too large, and you might be wasting space and budget.

Common lifting needs in defense operations include:

- Vehicle maintenance and recovery: lifting tanks, trucks, and mobile artillery

- Equipment transportation: loading and unloading containers, tools, and heavy electronics

- Weapon system support: positioning missile systems, radars, and launch platforms

- Base construction: handling steel beams, shelters, and building modules

The key is knowing the heaviest load and how often you'll lift it — then adding a safety buffer.

Durability and Reliability

Military cranes don’t operate in ideal conditions. Think sand, snow, rain, saltwater, or desert heat.

That’s why durability is non-negotiable. Your crane must keep working where commercial cranes would fail.

Here’s what to look for:

- Weather-resistant designs: sealed motors, rust-proof coatings, and temperature-tolerant parts

- Heavy-duty use: cranes built for long operation cycles, even under load

- Minimal downtime: reliable systems with fewer breakdowns and easy access for repairs

- Military-grade construction: reinforced steel, rugged components, and high-spec materials

You can’t afford delays during a mission or while moving critical supplies.

Mobility and Portability

Not all military tasks happen in fixed locations. Some cranes need to go where the action is — fast.

That’s where mobile or modular cranes come in.

Consider:

- Truck-mounted cranes: ideal for quick movement between zones or camps

- Rough terrain cranes: for off-road or undeveloped sites

- Compact portable cranes: easy to set up inside hangars, workshops, or containers

- Ease of transport: break-down design for air or land shipping, even in remote locations

If you’re relocating often, portability matters as much as strength.

Operational Efficiency

Defense work doesn’t just need power — it needs precision. A good crane should be fast, responsive, and safe to operate under pressure.

Efficient crane systems help complete tasks quicker and reduce manpower requirements.

What to keep in mind:

- Lifting speed: faster operations help during loading or emergency tasks

- Smooth controls: precision movement reduces the risk of damaging sensitive gear

- Automation options: remote control or semi-automatic functions for safety and ease

- Energy efficiency: saves fuel or power during extended use in field bases

Special Features for Military Cranes

Military operations often take place in demanding, high-risk, and unpredictable environments. That’s why cranes used in these settings need to go beyond the basics. They must be equipped with specialized features that improve safety, adaptability, and performance. Let’s break down what those are.

Explosion-Proof Capabilities

Many military cranes operate near volatile materials — ammunition, fuel, chemicals, or even missile systems. In such areas, even a small spark or heat source could cause a disaster. Explosion-proof cranes are designed to completely eliminate those risks.

They’re not just optional — they’re often mandatory in certain zones.

Where these cranes are commonly used:

- Ammunition storage bunkers

- Missile assembly areas

- Fuel depots and refueling zones

- Chemical warfare equipment storage

- Naval ships and submarine facilities

Key explosion-proof features include:

- Flameproof electrical enclosures: Prevent sparks from escaping

- Non-sparking components: Such as brass wheels, copper hooks, and bronze bushings

- Overheat protection: Temperature sensors to shut down the crane before it becomes unsafe

- Compliance with military and civilian standards: Such as ATEX (Europe), IECEx (global), NEC (U.S.), and various national defense specifications

These cranes help ensure that highly sensitive materials are handled safely and without incident, even during prolonged or repetitive use.

Remote Operation and Automation

Military environments can be dangerous, restricted, or logistically complex. Operators may need to work from a distance to avoid exposure to hazards, combat areas, or contaminated zones. That’s where remote and automated control systems come into play.

Benefits of remote operation in military use:

- Keeps personnel out of danger zones

- Allows operation in limited visibility or enclosed spaces (like hangars, submarines, or silos)

- Reduces manpower needs — one person can control multiple systems

- Offers better positioning accuracy through fine-tuned controls

Automation is increasingly used for:

- Repetitive lifting cycles during logistics and supply chain operations

- Aircraft maintenance, where precise alignment of components is required

- Smart warehouse cranes in base supply centers

- Crane coordination across different sectors using integrated defense software

Common automated features include:

- Pre-programmed lift paths

- Anti-sway technology for steady load movement

- Real-time diagnostics for performance monitoring

- System integration with military logistics platforms (e.g., SAP, ERP-based systems)

In high-stakes environments, automation and remote control help maintain performance without sacrificing safety or speed.

Weatherproof and All-Terrain Capability

Military cranes must perform anywhere — and we mean anywhere. Desert deployments, arctic outposts, jungle bases, and coastal docks all bring unique challenges.

That’s why weatherproofing and terrain adaptability are more than just nice to have — they’re essential.

Environmental factors military cranes must withstand:

- Extreme heat (Middle Eastern bases, African deserts)

- Sub-zero cold (Arctic stations, mountain warfare zones)

- High humidity (tropical and jungle regions)

- Salt air and water spray (naval and coastal operations)

- Dust storms and sand erosion (desert warfare or training areas)

Crane adaptations to meet these challenges:

- Sealed motors and enclosures to keep out dust, water, and ice

- Anti-corrosion coatings for all exposed steel components

- Heavy-duty tires or tracks to move across uneven ground, snow, or mud

- Cold-start hydraulic systems that work even in freezing temperatures

- Sun-shielded electronics to avoid overheating and sensor failure

Additionally, some military cranes are designed to be air-transportable, allowing them to be deployed quickly to forward operating bases using aircraft or helicopters.

If the crane can’t handle the climate or terrain, it could delay an entire mission. That’s not a risk military planners can take.

Crane Maintenance and Long-Term Support

Choosing the right crane for military use doesn’t stop at installation. What happens after deployment is just as critical — especially in defense environments where uptime and operational readiness are non-negotiable.

That’s why maintenance and long-term support should be factored into every crane procurement decision from the start.

Maintenance Requirements

Military facilities often operate far from major cities or technical hubs — in deserts, mountain zones, offshore platforms, or overseas bases. That makes ease of maintenance a top priority.

If a crane breaks down and you can’t fix it quickly, it may stall an entire operation.

Key maintenance considerations include:

- Accessible service points: Cranes should have maintenance-friendly designs — easily reachable grease points, plug-in diagnostics, and tool-free access to components when possible.

- Built-in monitoring systems: Sensors or software that track hoist usage, motor temperature, and wear-and-tear help predict issues before they lead to downtime.

- Simple modular components: Military personnel often perform basic servicing themselves. Modular parts (like plug-and-play motor units, gearbox assemblies, or control boards) allow fast replacement in the field.

- Minimal lubrication requirements: Dry or sealed bearings can reduce service needs in dusty or remote conditions.

Inspection and preventive maintenance matters too:

- Cranes in military zones should be inspected more frequently than standard commercial equipment.

- Monthly or even weekly checks may be needed for cranes used in high-load or hazardous conditions.

- Preventive maintenance schedules should be easy to follow and supported with military-specific documentation and checklists.

In short, the crane should be built not just to perform — but to be repaired quickly and kept running in the field.

Spare Parts and Support Availability

A crane isn’t just a one-time investment — it’s a long-term asset. But without a reliable supply of replacement parts and technical support, that asset can quickly turn into a liability.

In military operations, downtime isn’t just inconvenient — it can be mission-critical.

Key support factors to consider:

- Readily available spare parts: Look for suppliers with proven logistics — parts warehoused locally or within reach of your region.

- Compatibility across models: Cranes with standardized components reduce the need to stock a wide range of spares. This is especially helpful when multiple bases use the same equipment.

- Military logistics coordination: Work with manufacturers that understand export controls, defense compliance, and long-term supply contracts.

- 24/7 remote technical support: Fast answers matter. Look for partners offering remote diagnostics, video troubleshooting, or even on-call field technicians.

Strategic partnerships make the difference.

Military-grade crane suppliers should be prepared for the long haul. That means:

- Multi-year service agreements

- Scheduled performance audits

- Priority parts production in emergencies

- Engineering support for upgrades, retrofits, or relocations

Cranes used in military applications often stay in service for 15–25 years. Without committed, long-term support, even the most advanced crane can fall short when it matters most.

Compliance with Military Standards

Military cranes are subjected to the toughest conditions, demanding not only superior performance but also strict adherence to safety and operational standards. Compliance with these standards ensures that cranes can withstand the rigors of defense environments while ensuring the safety of personnel and assets.

Military Specifications (MIL-SPEC)

MIL-SPEC (Military Specifications) refers to the stringent guidelines established by the Department of Defense (DoD) for equipment used in military operations. These specifications define everything from materials and construction methods to design, performance, and safety standards.

Key aspects of MIL-SPEC compliance for cranes include:

- Durability and Reliability: MIL-SPEC cranes must be able to withstand extreme conditions, including harsh weather, corrosive environments, and high-impact operations. This means components need to be reinforced to resist damage during heavy use or combat conditions.

- Safety Standards: Cranes used in defense operations must meet precise safety requirements to prevent accidents in high-risk environments. This includes features like explosion-proof designs, overloading protection, and systems that reduce the risk of operator error.

- Operational Flexibility: Military cranes often need to be highly adaptable, capable of handling a wide range of loads, operating in tight spaces, and moving across different types of terrain. MIL-SPEC ensures that cranes meet these demands.

- System Integration: MIL-SPEC guidelines may also include requirements for integrating cranes into existing military systems or operational workflows, such as logistics or automated control systems.

Why compliance with MIL-SPEC is critical:

- Safety: Cranes that meet military standards ensure the safety of personnel, sensitive equipment, and expensive materials in often unpredictable and dangerous environments.

- Operational Efficiency: Compliance ensures that the crane performs reliably, even under heavy loads and in extreme conditions, allowing missions to proceed without unexpected delays or failures.

- Mission Readiness: MIL-SPEC cranes are built to withstand long periods of use, requiring minimal downtime and repair, which is essential for keeping military operations running smoothly in the field.

Certification and Testing

Certifications like CE, ISO, and others are often required for military-grade cranes to ensure that they meet both international and national standards for quality, safety, and performance. These certifications are not only proof of a crane’s capabilities but also provide guarantees regarding its reliability in military operations.

Key Certification Requirements:

- CE Certification: For European military operations, CE marking ensures that the crane complies with European Union safety, health, and environmental protection standards. This is crucial when deploying equipment across different countries in NATO or allied operations.

- ISO Certification: ISO certifications (like ISO 9001 for quality management and ISO 14001 for environmental management) confirm that the crane manufacturer adheres to international standards for quality and sustainable practices. These certifications assure military buyers that the cranes are built to the highest standards of performance and safety.

- Defense-Specific Certifications: Some cranes may require specialized certifications based on their specific use in military settings. This could include compliance with standards set by local defense agencies or international defense coalitions.

Routine Testing and Inspections:

Routine testing is critical to ensure that military-grade cranes continue to meet the stringent standards required for safe and efficient operation. Testing ensures the crane performs as expected, even in extreme conditions.

- Load Testing: Cranes should undergo regular load testing to ensure they can lift and carry heavy loads safely. This includes testing the lifting mechanisms, motors, and structures under full operational loads.

- Environmental Testing: Cranes should also be tested for environmental durability — including extreme heat, cold, humidity, saltwater exposure, and dust — to ensure they remain functional in military deployments worldwide.

- Safety Feature Testing: Features like anti-sway systems, overload protection, emergency braking systems, and fire-resistant components need regular inspection to ensure they continue to operate as designed.

- Performance Monitoring: Routine performance checks and diagnostics can help identify issues before they become critical. These checks may involve hydraulic systems, electrical components, and safety protocols.

Why routine testing and certification matter:

- Ensures Consistency: Regular testing ensures that the crane consistently meets military standards and performs reliably under a variety of mission conditions.

- Reduces Risk: Continuous certification and testing reduce the risk of equipment failure, which could compromise personnel safety or mission success.

- Compliance with Regulations: Meeting these standards is not just about performance — it’s also about ensuring compliance with defense regulations and international safety laws.

Crane Selection Process for Military Facilities

Choosing the right crane for a military base or defense facility is not just about lifting power. It’s about aligning with the mission. That means understanding the environment, the materials being handled, and the long-term goals of the operation. Below is a clear step-by-step approach to make sure the right crane is selected for the jo

Evaluating Military Needs

Before looking at crane models or brands, start with a clear needs assessment. Every military facility has its own demands, and the crane must match those specifics.

Ask these questions during the evaluation:

- What materials will be lifted?

Is it heavy armored vehicles, aircraft parts, weapon systems, fuel containers, or general supplies? The crane’s design and lifting attachments must suit the load types. - How often will it be used?

Occasional loading at a remote outpost is very different from 24/7 operations in a logistics hu - What’s the lifting environment like?

Indoor, outdoor, in the desert, coastal, arctic, or jungle? The location affects corrosion resistance, insulation, and weatherproofing needs. - What’s the required lifting height and span?

Some operations need high vertical reach or wide bridge spans for moving long military equipment or vehicles. - Are there space or movement limitations?

Tents, shelters, or low-ceiling repair bays might need low-headroom cranes or compact gantries.

Doing this groundwork helps avoid costly misfits and ensures the crane supports actual day-to-day defense operations.

Consulting Experts

Crane selection for military use should never be done in isolation. The best outcomes come when multiple experts work together — each bringing their technical knowledge and operational experience.

Why collaboration matters:

- Crane manufacturers with military experience know the specific certifications, environmental challenges, and load scenarios common in defense settings. They can recommend specialized models or custom modifications.

- Defense engineers understand how the crane will integrate with existing infrastructure or future expansion plans. Their input ensures the crane won’t be a bottleneck later.

- Logistics officers and field personnel know the practical side — how the crane will be used, what’s realistic in day-to-day operations, and how easy it is to maintain.

Involving the right team early on avoids overspending on features you don’t need — or worse, missing essential capabilities that become a problem during deployment.

Cost vs. Performance

Budget is always a concern. But when it comes to military cranes, going for the cheapest option can cost more in the long run.

The goal is value, not just low price.

Here’s how to strike the right balance:

- Compare lifecycle costs

Don’t just look at the purchase price. Consider installation, maintenance, energy use, expected lifespan, and support services. - Focus on mission-critical features

Avoid paying for unnecessary add-ons, but don’t skip on essential features like anti-sway, remote control, explosion-proofing, or extreme climate resistance. - Plan for the long-term

A more durable, efficient crane might cost more upfront but save thousands in downtime, repairs, and replacements over 10–20 years. - Explore flexible procurement options

Some suppliers offer phased upgrades, spare parts packages, or service agreements that reduce the total cost of ownership.

In defense operations, the crane isn’t just a machine — it’s a part of your mission infrastructure. It needs to be tough, efficient, and reliable from day one and for many years to come.

Conclusion

Selecting the right crane for military use isn’t a one-size-fits-all decision. It’s about matching the equipment to real operational demands—safely, efficiently, and for the long haul. Let’s quickly go over the key takeaways.

Summary of Key Factors in Crane Selection

When choosing a crane for a defense facility, several important factors need to come together:

- Load Capacity: Make sure the crane can handle both current and future lifting needs—whether it's small tools or armored vehicles.

- Durability and Reliability: Military cranes must survive tough environments and work continuously with minimal breakdowns.

- Mobility and Flexibility: Cranes should be easy to move, install, or adapt to different field locations and base layouts.

- Special Features: Consider explosion-proof options, weatherproof designs, and remote operation for safer, more efficient use.

- Standards and Compliance: The crane must meet military and international standards like MIL-SPEC, CE, and ISO to ensure safety and performance.

Together, these elements help ensure the crane supports mission readiness—without delays, downtime, or safety risks.

Final Recommendations

- Take the time to evaluate needs properly.

Look at the environment, lifting requirements, frequency of use, and future upgrades. Don’t rush the process. - Work with experts.

Choose manufacturers familiar with defense operations. Get input from engineers, logistics officers, and field staff. - Don’t underestimate long-term support.

Maintenance access, spare parts availability, and responsive technical support are just as important as the crane itself. - Balance cost and performance wisely.

Focus on value, not just price. A well-chosen crane will pay for itself in uptime, safety, and mission success.

In the end, military operations rely on strong infrastructure—and cranes are a vital part of that. Choose carefully, and your crane will serve the mission faithfully for years to come.