16 Ton Single Girder Overhead Crane for Belarus

Yuantai Crane's 16-ton single girder overhead crane, designed for Belarus’s industrial needs, offering reliability, strength, and efficiency.

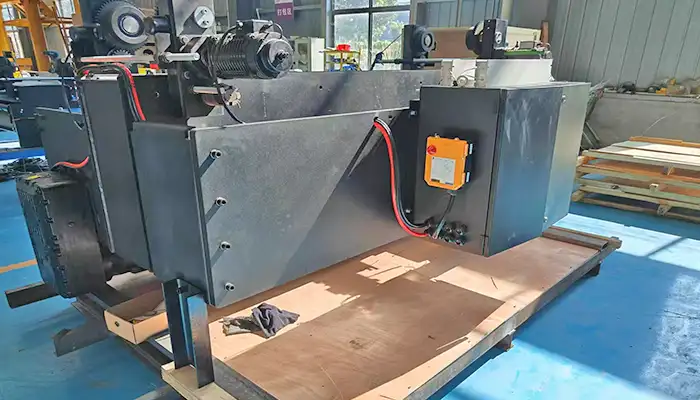

16 Ton Single Girder Overhead Crane Kit Without Main Girder Project Overview

This project is for a manufacturing company based in Belarus. The client placed the order on May 11, 2024, after a few rounds of technical discussions and solution matching.

The customer needed a reliable lifting solution for handling heavy materials in their indoor workshop. They had specific requests for lifting height, power supply compatibility, and equipment quality. We provided two types of cranes—each carefully chosen to match different working zones and tasks in the plant.

HD single girder overhed crane complete system, in the 16 ton overhead crane kit , the main girder is not included.

Products Supplied

HD-Type Single Girder Overhead Cranes (European-style)

- Quantity: 2 sets

- Lifting Capacity: 16 tons

- These cranes are used for general workshop lifting work.

- The client needed high lifting height (30 meters), and our HD model was a perfect fit.

Client Requirements

The client was looking for a complete lifting solution for their indoor manufacturing workshop. Their production process involves moving heavy loads regularly, so they needed equipment they could count on—day in and day out.

We spent time understanding their actual working conditions. Based on that, these were the key requirements they shared:

Main Needs

- High lifting capacity

The cranes needed to handle large, heavy materials safely. A 16-ton capacity was a must. - Compact structure

The workshop had existing steel frames and a limited ceiling height. So, the crane design had to be compact and space-efficient. - Lifting height of 30 meters

They needed enough vertical travel to lift and lower tall components with ease. - European-style hoist system

The client preferred a modern, low-maintenance hoist with smooth movement and low noise. - Power compatibility

Equipment had to match the local standard: 380V, 50Hz, 3-phase. No adjustments on-site. - Cold climate durability

Since Belarus has cold and humid seasons, the crane had to operate well without rust or electrical issues.

We made sure to address each of these points in the design and configuration. No overcomplicated solutions—just what works best for their workshop.

Product Configuration

HD-Type Single Girder Overhead Crane

For the main lifting tasks, we supplied two sets of 16-ton HD-type single girder overhead cranes. These are European-style cranes equipped with low headroom electric wire rope hoists. This model is widely used in modern workshops that need a balance between performance and space-saving design.

The client’s workshop had limited clearance between the crane beam and the roof structure. So, our low headroom design made full use of the available space—without compromising lifting height.

Technical Specs

- Lifting Capacity: 16 tons – Ideal for heavy-duty materials like metal components and assemblies.

- Span: 10.5 meters – Matching the workshop’s bay width for full coverage.

- Lifting Height: 30 meters – A key requirement for lifting tall items from ground to high storage areas.

- Quantity: 2 sets – Installed in two different bays to support continuous workflow.

Key Features and Benefits

Low Headroom Design

- Minimizes the space between the beam and hook.

- Allows for higher lifting range even in workshops with limited ceiling height.

Energy-Efficient Operation

- European-style motors and frequency inverters ensure smooth starts and stops.

- Reduces energy usage and wear on components over time.

Modular Structure

- Easier and faster to install on-site.

- Simplifies future maintenance and spare part replacement.

Wire Rope Hoist with Smart Features

- Designed for steady load control.

- Comes with safety limit switches, thermal protection, and overload guard.

This crane setup offers a strong mix of safety, durability, and ease of use—exactly what the client needed to improve efficiency in daily operations. Let me know if you'd like me to expand the jib crane section in the same style.

Single Girder Overhead Crane Kit without Main Girder

Our Single Girder Overhead Crane Kit provides a complete lifting solution that includes all necessary components for assembly and operation. The kit is designed to be easy to install, cost-effective, and adaptable to various workshop requirements. This setup includes a main girder, which is the backbone of the crane, supporting the hoisting system and ensuring smooth operation.

End Beams

- Support the main girder and connect it to the crane runway.

- Ensure smooth movement along the tracks.

- Equipped with bearings for quiet operation and minimal wear.

Hoist System

- Typically includes a wire rope hoist or electric chain hoist, depending on lifting capacity.

- Can be European-style for high efficiency and low maintenance.

- Comes with limit switches and overload protection for safety.

Control System

- Comes with a pendant controller or wireless remote control.

- Allows for precise operation with smooth start/stop functionality.

- Can be equipped with safety features like emergency stop buttons.

Electrical Components

- Includes motors, drives, and electrical panels.

- Configured to suit local power supply (e.g., 380V, 50Hz, 3-phase).

- Ensures energy-efficient operation and long service life.

Features and Benefits

- Customizable Design

The crane kit can be tailored to fit specific workshop dimensions and lifting requirements, offering flexibility in span, capacity, and height. - Space-Efficient

The single girder design ensures that the crane occupies minimal headroom, maximizing available space in low-ceiling workshops. - Easy Assembly

The kit is designed for simple, quick assembly, with all components provided in a modular format. It reduces the need for extensive installation work. - Cost-Effective

Ideal for small to medium-sized workshops where efficiency and cost savings are a priority. - Safety Features

Equipped with safety limit switches, overload protection, and emergency stop functions, ensuring safe operation at all times.

Applications of Single Girder Overhead Crane Kit

- Light to Medium Duty Lifting

Perfect for workshops handling loads up to 10-20 tons, such as materials handling, machine maintenance, and assembly operations. - Ideal for Low-Ceiling Areas

Due to the low headroom design, the crane can operate in spaces where vertical clearance is limited. - Industries Served: Manufacturing, Steel Mills, Machine Workshops, Warehouses and Distribution Centers,

Why Choose Our Crane Kit?

- Reliable and Durable

With high-quality materials and advanced design, this crane kit is built to last and handle frequent, heavy-duty use. - Flexible and Modular

Easy to adjust the crane’s configuration for future expansions or modifications, helping your business grow. - Professional Support

From technical advice to after-sales service, we provide full support throughout the installation and operation stages.

Engineering and Customization Highlights

- Customized Lifting Height: One of the key requirements from the client was a lifting height of 30 meters. Our team worked closely with the client to customize the crane’s lifting height to meet the specific dimensions of their workshop. This ensured that the crane could handle tall materials and lift them to the required storage levels, without any space limitations.

- Matching Belarus’s Industrial Voltage Standards: We designed the cranes to match the standard industrial voltage in Belarus—380V, 50Hz, 3-phase power supply. This meant that no additional electrical adjustments were needed on the client’s end, ensuring smooth installation and reliable operation straight out of the box.

- Compact Structure for Limited Headroom: Given the limited ceiling height in the client’s workshop, we incorporated a low headroom design into the crane configuration. This compact structure maximized the available space, allowing the crane to operate without interfering with the building’s framework while still providing the full lifting height required. This space-saving design was crucial to meet the workshop’s specific layout and keep operations running smoothly.

- Anti-Corrosion Finish for Harsh Climate Conditions: Considering Belarus’s cold and humid climate, we used an anti-corrosion surface treatment on all exposed crane parts. This coating prevents rust and deterioration, ensuring the cranes perform reliably even in the harshest weather conditions. The treatment extends the lifespan of the cranes and reduces maintenance costs, making them ideal for use in cold, industrial environments.

Manufacturing and Quality Control

The cranes were manufactured at Yuantai Crane’s certified factory in Xinxiang, China, where we adhere to the highest standards of production. Our factory is equipped with advanced machinery and experienced technicians who ensure each component is built to last.

Quality Assurance Process

- CE and ISO-compliant production: We follow strict CE and ISO-certified production standards to ensure the cranes meet both international safety and quality requirements.

- Third-party inspection: Before shipment, we arrange for third-party inspection to verify that all components meet the agreed specifications. This helps the client feel confident in the quality and performance of the cranes.

- Comprehensive testing: Every crane and its parts are tested and pre-assembled at our factory to ensure smooth operation. We conduct rigorous tests on hoists, motors, and control systems to guarantee the cranes perform at their best when they reach the client.

Logistics and Delivery

Once production was complete, we organized everything to ensure the cranes would be delivered on time and in perfect condition.

Key Logistics Highlights

- Export logistics: We coordinated sea freight logistics to deliver the cranes to Belarus. Our team handles all customs paperwork and shipping arrangements, so there are no delays in the process.

- Weatherproof packaging: Each crane was carefully packaged for sea transport, using weatherproof protection to ensure the equipment would arrive in excellent condition, no matter the weather during the transit.

- Timely delivery: The cranes were dispatched on schedule and delivered according to the agreed timeline. We made sure the client had everything they needed, right when they needed it.

Client Feedback and Future Outlook

Initial Feedback

While the post-installation review is still pending, the initial feedback from the client has been very positive. They particularly appreciated:

- Technical adaptability: The cranes were custom-designed to meet the client’s specific workshop dimensions and operational needs, and they were happy with how well everything fit together.

- Timely communication: Throughout the project, our team maintained clear, prompt communication. The client felt well-informed at every stage of the process, from initial design discussions to shipping updates.

Future Collaboration

Looking ahead, the client has expressed a strong interest in continuing the partnership for future lifting projects. They are pleased with the performance of the equipment and the support we provided, and they foresee additional opportunities for crane solutions as their operations grow.

We are excited about the possibility of future collaborations and are committed to offering high-quality products and service every step of the way.

Why the Client Chose Yuantai Crane

The client chose Yuantai Crane for several key reasons that aligned perfectly with their needs and expectations:

- European-Standard Quality at Competitive Prices : Yuantai Crane offers European-standard quality cranes, which are built with precision and durability. Our cranes are designed to perform at the highest levels while still being cost-effective. Thanks to our factory-direct pricing, the client received top-tier equipment without the added costs typically associated with middlemen.

- Fully Customizable Lifting Solutions: Every project has its unique requirements. Yuantai Crane is known for providing fully customizable lifting solutions that are tailored to fit the client’s specific needs. Whether it's adjusting the lifting height, span, or hoist configuration, we worked closely with the client to design cranes that perfectly suited their workshop layout and operational demands.

- Dedicated Technical Support: From the very first conversation to the final installation, dedicated technical support was provided every step of the way. Our team offered valuable insights during the design phase, assisted with procurement decisions, and ensured the installation process went smoothly. The client appreciated our proactive approach and constant availability to address any concerns.

- Proven Export Experience: Yuantai Crane has a long history of exporting cranes worldwide, which gave the client confidence in our ability to deliver on time and meet international standards. We’ve worked with businesses across different industries and countries, ensuring reliable equipment and professional service regardless of geographical location.

Send us an inquiry on 16 ton overhead crane or single gider overhead crane kit .