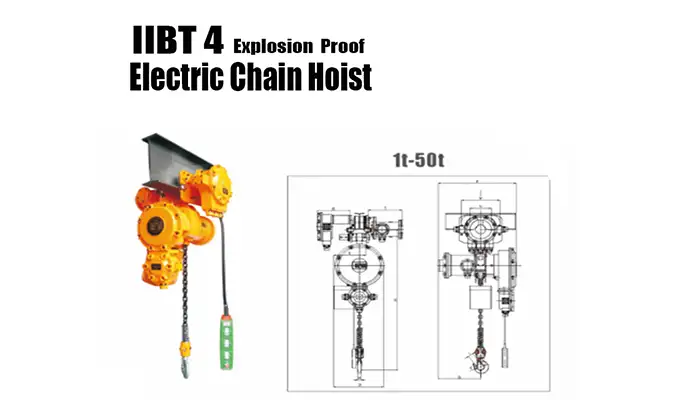

Durable explosion-proof electric chain hoists from 1 to 50 tons, certified for hazardous gas zones, ideal for safe lifting. Get ur explosion proof hoist!

Why You Need the Right Hoist for Hazardous Environments

Some workplaces have more than just heavy loads—they have gas risks too. In places like oil refineries, chemical plants, or gas stations, even a small spark can lead to serious danger.

That’s why using a regular electric hoist isn't enough.

What Makes Explosion Protection So Important

In areas with flammable gases, safety is everything. Electrical equipment, including hoists, must be built to stop sparks from escaping.

If gas is present and a normal motor sparks, it could cause an explosion. That’s the risk we help you avoid.

Explosion-proof electric hoists are specially made for this. They are built to work safely in explosive gas zones—Zone 1 and Zone 2.

Meet the Gas Explosion-Proof Electric Chain Hoist

We offer a hoist designed just for these tough situations. It’s called a gas explosion-proof electric chain hoist.

- It's an electric chain hoist, meaning it lifts loads using a motor and strong load chain.

- It’s also an explosion proof hoist, meaning it’s made to work safely where gas might be in the air.

This hoist is not just about lifting—it’s about lifting safely, even in the most dangerous conditions.

If you work in a gas-prone area, this hoist could be the right tool for your team.

Application of Explosion Proof Electric Chain Hoist for Explosive Gas Working Environments

Where Explosion-Proof Electric Chain Hoists Are Essential

Not all environments are safe for standard lifting equipment. Some workplaces constantly deal with flammable gases, vapors, or chemical mists. In these places, a regular hoist could become a serious hazard.That’s why a gas explosion-proof electric chain hoist is the preferred choice in hazardous areas. It’s not just about lifting heavy loads — it’s about lifting them safely where explosions could occur.

Key Industries That Use Explosion-Proof Hoists

These are the industries where using explosion-proof lifting equipment is not optional — it's required for safety compliance and operational protection:

- Petrochemical Plants

These facilities handle raw petroleum and convert it into products like gasoline, diesel, and plastics. During production, flammable gases such as propane, butane, and ethylene are released. These gases can accumulate in enclosed or poorly ventilated spaces.

Explosion-proof hoists are required in maintenance areas, pump rooms, and filling zones.

- Oil & Gas Refineries

Refineries process crude oil, and many stages release explosive gases or vapors. Frequent lifting is needed for heavy valves, pipelines, or maintenance tools.

Safe lifting is critical in tank farms, distillation towers, and storage areas.

- Gas Storage Terminals and Filling Stations

Large-scale or even local gas stations involve bulk transfer of fuel. A small spark from a regular hoist motor could ignite vapors.

Explosion-proof hoists are used for tanker maintenance and parts handling.

- Paint Workshops and Coating Lines

Paints, solvents, and thinners contain volatile organic compounds (VOCs) that can ignite easily. Spray booths and mixing rooms are high-risk zones.

Certified hoists ensure no electrical sparks occur during lifting or positioning equipment.

- Chemical Manufacturing Plants

Facilities that produce or store industrial chemicals are filled with airborne risks like ammonia, acetone, or hydrogen.

Explosion-proof hoists are used for loading reactors, transferring drums, or servicing machinery.

- Pharmaceutical Plants

Some active pharmaceutical ingredients involve flammable solvents during processing.

Cleanroom-safe and explosion-proof lifting systems are often required.

Hazardous Zones (Gas Atmospheres)

Electrical equipment is classified by the zone it is designed to operate in. When it comes to gas explosion hazards, two main zones apply:

- Zone 1 – High Risk

A place where explosive gas atmospheres are likely to occur during normal operations. For example, near gas release valves or open processing equipment.

- Zone 2 – Moderate Risk

A place where explosive gases are not normally present, but if they are, they occur infrequently and for short periods. For example, in areas close to processing rooms or emergency vents.

Our explosion proof electric chain hoists are certified for both Zone 1 and Zone 2, giving you safe and compliant lifting options no matter the risk level.

Typical Hazardous Environment Conditions

Here’s what these environments usually look like:

- Air contains flammable gases or chemical vapors during normal or unexpected operations

- Limited ventilation, so gases may build up over time

- High temperatures, increasing the risk of spontaneous ignition

- Electrical sparks are dangerous, so all equipment must be sealed and explosion-proof

- Strict compliance requirements (ATEX, IECEx, etc.) — violations can shut down production

Explosion Protection Standards

Built for Dangerous Environments

In hazardous workplaces, safety starts with certified equipment. A gas explosion-proof electric chain hoist must meet strict safety standards. These standards are designed to prevent the hoist from becoming a source of ignition.

Explosion-Proof Classification: What “Ex d IIB T4 Gb” Means

This code tells you exactly how the hoist handles explosive gas risks:

- Ex – Explosion-proof equipment

- d – Type of protection: "Flameproof enclosure." If an explosion happens inside, it won't escape.

- IIB – Gas group. Suitable for most industrial gases, including ethylene.

- T4 – Temperature class. The maximum surface temperature of the equipment will not exceed 135°C.

- Gb – Equipment protection level. “Gb” means high protection for Zone 1 gas areas.

In simple terms: this hoist is safe to use in areas with flammable gases and vapors. It’s made to avoid causing sparks or overheating.

Compliance with International Safety Standards

Our explosion-proof electric chain hoists meet global safety requirements. That includes:

- ATEX Certification (Europe)

Required for equipment used in potentially explosive atmospheres within the EU.

- IECEx Certification (International)

A globally recognized system for verifying that explosion-proof equipment meets strict standards.

- Chinese GB Standards (for domestic markets)

Follows national safety codes for explosion-proof equipment used in Zone 1 and Zone 2.

Using a certified hoist means peace of mind for buyers, workers, and regulators.

Safe Surface Temperature: T ≤ 135°C

When the hoist runs, parts like the motor or control box can get hot. But in explosive gas environments, the surface must stay below the ignition point of surrounding gases.

This hoist is rated T4, meaning:

- It will never exceed a surface temperature of 135°C, even under load.

- This prevents surrounding gases or vapors from igniting due to contact with hot surfaces.

This safety level is suitable for most gases found in industrial workplaces.

Key Features

Built for Hazardous Work, Down to Every Detail

Explosion-proof electric chain hoists are not just standard hoists with labels — they’re specially designed from the inside out for use in gas-prone environments. Below are the critical components that make these hoists safe and reliable.

Explosion-Proof Components

Every part that could produce a spark or heat is sealed, reinforced, or certified for safety.

Explosion-Proof Hoist Motor

- Fully enclosed to keep out flammable gases and dust

- Made from thick, cast iron for better flame resistance and heat control

- Designed to operate continuously without overheating

Explosion-Proof Control Pendant

- Certified for use in hazardous areas

- Features a sealed, ergonomic design

- Clear button layout, easy to operate even with gloves

Explosion-Proof Electrical Box

- Uses flameproof thickened cast iron housing

- Internal wiring is shielded and routed to prevent sparks

- External screws and joints are sealed tightly

Stainless Steel Fasteners

- All bolts, screws, and hardware are stainless steel

- Corrosion-resistant, especially important in chemical or offshore sites

- Non-sparking to further reduce ignition risk

Lifting Components

The lifting mechanism is equally robust, made to perform safely and efficiently in explosive environments.

Load Chain

- Made from G80 high-strength alloy steel

- Copper-plated surface to reduce friction and prevent sparking

- Durable enough for daily lifting, yet smooth to reduce wear

Hook

- Crafted from solid stainless steel for strength and spark resistance

- Swiveling design allows easy load rotation

- Comes with a spring-loaded safety latch to prevent accidental slips

Chain Container

- Options include anti-static plastic or metal casing

- Prevents the loose chain from contacting other equipment or materials

- Helps maintain a clean and safe work area

Control Options

- Pendant control with emergency stop

- Optional wireless remote (explosion-proof certified)

- Variable frequency drive (VFD) for smooth operation (optional)

Technical Specifications

Built for Flexibility and Heavy-Duty Use

Our explosion-proof electric chain hoists are designed to handle a wide range of lifting needs in hazardous environments. Below are the core specifications:

| Specification |

Details |

| Lifting Capacity |

0.5 ton to 50 tons (customized per project requirements) |

| Mounting Types |

- Hook Mounted- Electric Trolley Mounted- Manual Trolley Mounted- Low Headroom Design |

| Lifting Height |

Standard: 3 m, 6 m, 9 mCustom heights available upon request |

| Lifting Speed |

Fixed speed or dual speedOptional VFD for smoother control |

| Control Methods |

- Pendant Control (Standard)- Wireless Remote (Optional)- VFD (Optional) |

| Power Supply |

3-phase: 220V / 380V / 415V, 50Hz or 60Hz |

| Duty Cycle |

Medium to heavy-duty, designed for frequent industrial use |

Lifting Capacity

- Standard range: 0.5 ton to 50 tons

- Customized for various applications and load conditions

Mounting Types

Choose the configuration that fits your setup:

- Hook Mounted: For simple hanging use

- Electric Trolley Mounted: Motorized travel along I-beam or track

- Manual Trolley Mounted: Manual push/pull travel, cost-effective

- Low Headroom Design: Ideal for workshops with limited overhead space

Lifting Height

- Common options: 3 m, 6 m, 9 m

- Customized heights available upon request

Lifting Speed & Control Method

- Fixed or dual-speed available

- Optional VFD for smooth acceleration and deceleration

- Control precision helps protect the load and structure

Power Supply

- Voltage options: 220V / 380V / 415V, 3-phase

- Frequency: 50Hz or 60Hz

- Can be adapted to your country’s standards

Duty Cycle

- Suitable for medium to heavy-duty operations

- Built for frequent, reliable lifting in explosive atmospheres

Safety and Reliability

Safety is the top priority when working in hazardous environments. Our explosion-proof electric chain hoists come equipped with multiple features to ensure dependable and safe operation.

Overload Protection

- Prevents the hoist from lifting loads beyond its rated capacity

- Automatically stops lifting to avoid mechanical damage or accidents

Mechanical and Electrical Limiters

- Upper and lower limit switches stop the hoist at the safe travel endpoints

- Protects the hoist from over-travel and reduces wear on components

Heat-Resistant Insulation and Flameproof Cabling

- Special insulation materials withstand high temperatures and prevent ignition

- Flameproof cabling resists sparks and electrical faults that could ignite gas or dust

Long Service Life in Harsh Environments

- Robust design using corrosion-resistant materials like stainless steel fasteners

- Heavy-duty cast iron housings protect internal parts from dust, moisture, and chemicals

- Reliable operation even under frequent use and tough conditions

Why Choose Explosion Proof Hoist

Selecting the right hoist is critical for safety and efficiency. Here’s why our explosion-proof hoists stand out:

Certified and Tested for Hazardous Zones

- Fully compliant with international explosion-proof standards such as ATEX and IECEx

- Tested to perform safely in Zone 1 and Zone 2 gas atmospheres

Heavy-Duty Design with Reliable Performance

- Built to handle heavy loads with smooth, precise control

- Durable components reduce downtime and maintenance costs

Customization Available

- Lifting height, speed, and capacity tailored to your specific needs

- Various control options (pendant, wireless remote, VFD) to fit your operation style

Backed by Expert Support and After-Sales Service

- Technical guidance from experienced engineers

- Prompt spare parts supply and maintenance support

- Training and documentation provided for safe operation

Conclusion

Key Benefits of Gas Explosion-Proof Electric Chain Hoists:

- Provides safe lifting in explosive gas environments

- Offers reliable performance even in harsh conditions

- Features customizable options to suit various industrial needs

- Ensures efficient and smooth material handling

This hoist is the smart choice for any facility needing safety and efficiency where gas hazards exist.

Need Help Selecting the Right Hoist?

- Get free technical consultation from our experts

- Request a customized quotation tailored to your requirements

Contact Us Today

We’re ready to assist you in choosing the perfect explosion-proof electric chain hoist for your hazardous workspace.