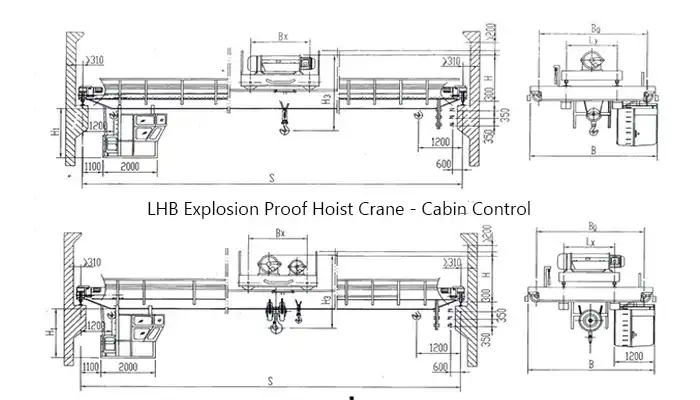

Double Girder Explosion-Proof Crane with Electric Hoist (LHB)

Heavy-duty explosion-proof crane designed for hazardous environments, featuring dual girders and electric hoist for safe, reliable material handling.

The LHB Explosion-Proof Bridge Crane is a heavy-duty, double girder overhead crane specially designed for hazardous industrial environments where explosive gases, vapors, or dust may be present. This crane is engineered to ensure safety, reliability, and durability while handling loads ranging from 1 to 63 tons.

Key Features

- Hoisting Capacity:

Ranges from 1 ton up to 63 tons, suitable for a wide variety of heavy lifting tasks in explosive environments.

- Operating Temperature Range:

Designed to operate safely in temperatures from -25°C to +40°C, allowing use in cold storage, chemical plants, and other temperature-sensitive areas.

- Explosion-Proof Compliance:

Fully compliant with GB3836.1-2000 and GB3836.2-2000 standards, which govern explosion-proof electrical equipment in China.

The electrical components and motors are certified explosion-proof to:

Exd II BT4 level (for general explosive atmospheres)

Exd II CT4 level (for more stringent environments requiring additional spark-proof protection)

- Explosion-Proof Electric Hoists:

Equipped with the HB and BCD series explosion-proof electric hoists, designed for safe and reliable lifting in hazardous areas.

These hoists meet the same explosion-proof classifications as the crane itself, ensuring system-wide protection.

- Spark-Proof Travelling Mechanism:

For cranes classified as Exd II CT4, the travelling mechanisms (trolley and bridge movements) include special spark-proof treatments to prevent ignition sources caused by friction or sparks during operation.

- Double Girder Structure:

Provides superior strength, stability, and lifting performance compared to single girder cranes, making it suitable for heavier loads and longer spans.

- Adaptability to Hazardous Environments:

Ideal for use in factories and plants where the atmosphere contains flammable gases or vapors classified as explosion group B or C, with ignition temperatures above 135°C (T4 group).

![Economical explosion proof overhead crane with economical BCD explosion proof wire rope hoist]()

LHB Explosion-Proof Double Girder Bridge Crane – Main Specifications

| Item |

Specification |

| Crane Model |

LHB Explosion-Proof Bridge Crane |

| Lifting Capacity |

1t, 2t, 3t, 5t, 10t, 16t, 20t, 32t, 50t, 63t |

| Span Range |

7.5m to 31.5m (customizable) |

| Lifting Height |

6m, 9m, 12m, 18m, or customized |

| Lifting Speed |

3.5 – 8 m/min (varies by hoist model and capacity) |

| Trolley Travelling Speed |

20 m/min (standard; variable frequency optional) |

| Crane Travelling Speed |

20 – 30 m/min (standard; variable frequency optional) |

| Working Class (Duty Group) |

A3 – A5 (light to medium duty per GB/T 3811) |

| Working Environment |

Indoor; Explosive gas mixture environment (Zone 1 or 2) |

| Explosion-Proof Grade |

Exd II BT4 / Exd II CT4 |

| Ignition Temperature Group |

T4 (≤135°C) |

| Power Supply |

3-Phase, 380V 50Hz (custom voltage on request) |

| Control Mode |

Pendant Control / Remote Control / Cabin (optional) |

| Ambient Temperature |

-25°C to +40°C |

| Relative Humidity |

≤85% (non-condensing) |

| Hoist Type |

HB or BCD Explosion-Proof Electric Wire Rope Hoist |

| Motor Protection Grade |

IP54 / IP55 |

| Insulation Class |

F or H Class (depending on model) |

| Limit Protection |

Lifting limit switch, travel limit switch, overload limiter |

| Optional Features |

Anti-collision, inverter control, flameproof lighting |

Note: The above specifications are for your reference only. Customized designs are available to meet your specific application requirements. Please feel free to contact us for a tailored solution or a free quotation.

Technical and Safety Highlights

- Explosion-Proof Motor & Electrical Components:

Motors, control panels, wiring, and electrical parts are all designed and sealed to prevent ignition of surrounding explosive atmospheres.

- Spark-Proof Design:

The travelling mechanisms are specially treated or equipped with anti-spark devices when operating under Exd II CT4 conditions.

- Robust Structural Design:

Double girder frame made of high-quality steel ensures mechanical rigidity and durability under continuous industrial operation.

- Certifications:

The crane system adheres strictly to relevant Chinese national standards (GB3836 series) for explosion protection, ensuring compliance with industrial safety regulations.

![Economical explosion proof overhead crane with economical BCD explosion proof wire rope hoist]()

Applications

This explosion-proof double girder bridge crane is commonly used in:

- Chemical and petrochemical plants

- Oil refineries

- Pharmaceutical manufacturing

- Mining and metal processing plants

- Any industrial environment with flammable gas or dust hazards classified under Group B or C and temperature class T4.

Case Study: 4 Sets of Customized LHB Explosion-Proof Hoist Cranes Delivered to Yemen

A client in Yemen specializing in hazardous material processing required explosion-proof lifting solutions for a high-risk industrial zone. To meet their operational and safety demands, we provided 4 sets of customized LHB Double Girder Explosion-Proof Hoist Cranes equipped with traditional wire rope hoist trolleys.

![5 ton explosion proof hoist crane for sale]()

Delivered Configuration:

- 2 sets of LHB 5t-3.75m explosion-proof hoist cranes

- 2 sets of LHB 5t-5.75m explosion-proof hoist cranes

Each crane was built to Exd II BT4/CT4 standards, ensuring full compliance with international explosion-proof safety requirements. The compact span designs (3.75m and 5.75m) were tailored to fit the client's limited workshop layout while maintaining optimal lifting performance.

These cranes are now operating reliably in Yemen, providing safe and efficient material handling in a high-risk zone involving flammable gases and vapors.

Need a similar solution? Contact us for customized explosion-proof crane systems that meet your exact safety and operational requirements.