Grab overhead cranes & bridge cranes, equipped with clamshell grab bucket, orange peal grab or tailored crane grab for different bulk loads handling. Check now.

Grab overhead cranes & bridge cranes, equipped with clamshell grab bucket, orange peal grab or tailored crane crane grab for different bulk loads handling. For your particular loads handling, there tailored grab overhead crane and grab bridge cranes are available. In the following, the main types of grab bucket overhead cranes are presented for your reference to most cost-effective grab bucket crane for your application.

Single Girder Grab bucket Overhead Crane with Hoist Trolley

Grab cranes come in a range of capacities and sizes to handle large amount of bulk materials efficiently and safely. With wealth of experience in crane manufacturing industry, we can provide customers with superior quality overhead cranes custom designed to meet all kinds of lifting requirements. These cranes come in two basic configurations, single girder and double girder overhead cranes.

The single girder overhead crane are used for light loads handling with capacity no more than 10 ton. Compared with double girder grab overhead crane, the single girder designed one is much less expensive. It mainly uses the suspension electric wire rope hoist as the lifting system, with the grab bucket attached down below for loads handling. For light bulk material handling, it will be a very economical solution.

Single girder grab bucket crane parameters:

- Load capacity: 1-10t

- Span: 10.5-31.5m

- Lifting height: 6-26m

- Lifting speed: 30.7-39.3m/min

- Trolley running speed: 31.1-44.6m/min

- Crane running speed: 76.9-93.6m/min

- Work duty: A5-A7

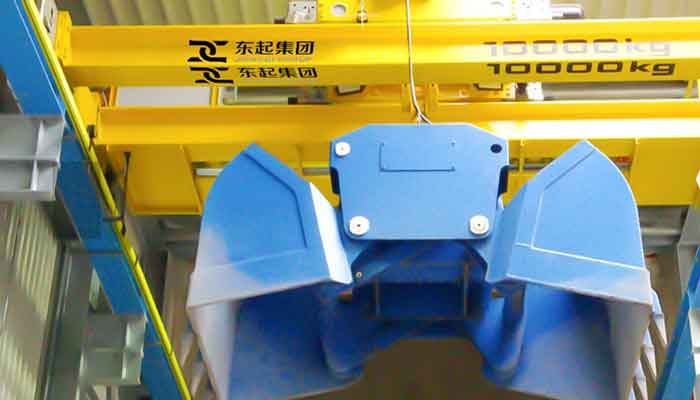

Double girder grab overhead crane

The development and evolution of the double girder bridge crane resulted in the development of the grab overhead crane, which may be used for lifting and handling granular materials, minerals, steel scrap, wine tanks, slag, coke, coal, sand, and other, etc. The bridge crane can be used indoor applications and outdoor uses, where a rain-proof system is installed. Its rated crane capacity of grab bucket overhead crane should include the dead weight of the grab bucket devices and with weight of the loads that needs to handle at a time.

Grab Bridge Cranes With Open Winch Trolley

Grab bridge cranes with double girder design can be equipped with the hoist trolley for loads handling with capacity from 5 ton -25 ton.

If you would like one grab crane a higher level performance, we would like to recommend to you this one. Because, the overhead crane grab is widely used in loading goods in port, factory, workshop, and power plant. Such a multi-functional grab crane can meet the work requirements. It mainly because that the work classification is heavy. At the same time, the lifting capacity includes the weight of the grab. And this one may be your reasonable choice.

The double girder grab overhead crane is used when heavy duty material handling is required . Because it is frequently used to load items at ports, factories, workshops, and power plants, etc. The multi-functional grab bucket overhead cranes can well meet your material handling needs.

Double girder grab bucket crane parameters:

- Load capacity: 5-25t

- Span: 10.5-31.5m

- Lifting height: 6-26m

- Lifting speed: 30.7-39.3m/min

- Trolley running speed: 31.1-44.6m/min

- Crane running speed: 76.9-93.6m/min

- Work duty: A5-A7

double girder overhead crane with orange peal grab

And also for sspecial application, the double girder overhead cranes can be equipped with special designed grab such as hydraulic grab and rope grabs to handling different loads and used in different applications. And also ton ensure a constant flow of material handling in busy production line or processing line, such as waste handling center or steel scrap handling steel mill, the grab bucekt overhea crane can be designed with full and semi-automated control system to remove operator fatigue, increase positioning accuracy, productivity, and safety, and at the same time reducing operating costs, etc.

Open winch trolley for double girder grab bridge crane

Main features of Refuse & Waste Grab Cranes:

- Full Or Semi-Automated Control System

- Orange Peel Or Clamshell Hydraulic Grabs

- Sway Control

- Anti-Collision

- Process Management System

- Web-Based Remote Maintenance And Diagnostic Systems

Clamshell grab bucket overhead crane & Orange peal grab bucket overhead crane

According to the driving method of crane grab, grab overhead cranes can be can be divided into two types: hydraulic grab and mechanical grab. And also according the types of crane grab buckts, the grab overhead cranes can be grouped into clamshell grab crane & orange peal grab crane, etc.

Overhead c rane grabs are classified into two types: orange grabs and clamshell grabs. Yuantai Crane 's clashell buckets offerings are as follows:

Clamshell Buckets are used to load and unload materials such as sands, coal, mineral powder, and bulk chemical fertilizer. The Clamshell Bucket is designed to allow the overhead crane to grab bulk materials efficiently .

Crane peel grab for sale. Crane peel grabs are available in a variety of tine configurations, including 4 tine peel grabs, 5 tine peel grabs, 6 tine peel grabs, and so on. Yuantai Crane peel grab can handle scrap metal, waste and demolition products, coal, and other materials,etc.

- Hydraulic grab crane - The hydraulic grab has an opening and closing structure that is typically powered by a hydraulic cylinder. A hydraulic claw is another name for a hydraulic grab with multiple jaws. Hydraulic grabs are a common component of hydraulic special equipment.

- Mechanical grab crane -The mechanical grab has no opening and closing structure and is usually powered by a rope or a connecting rod. It is classified as a double rope grab or a single rope grab based on its operation characteristics. A double rope grab is the most frequently used grab bucket.

A support rope and an opening and closing rope are wound around the support mechanism and the reel of the opening and closing mechanism, respectively, in the double rope grab. The double rope grab is dependable, simple to use, productive, and widely used. When two sets of double ropes are used, it becomes a four-rope grab, with the same working process as the double rope grab. The single rope grab uses the same rope for the support rope, as well as the opening and closing rope.

The wire rope rotates to provide support and is opened and closed by a special locking device. The single rope grab's winding mechanism is simple, but its productivity is low, and it is rarely used in a large number of loading and unloading operations.

General Applications Of Grab Cranes

- Main Application

- Widely used for loading, unloading, and transferring bulk materials in power plants, garages, workshops, and docks, among other places.

- The rated capacity includes the weight of the grab.

- Not for use in flammable, explosive, or corrosive media environments.

Applicable Scope & Working Conditions

This crane is used in ambient temperature of -25℃~+40℃,humidity≤85%,elevation is under 1000m,power supply is 3-ph, 380V,50HZ (can change as user demand).

Characteristics of crane grab

|

Grab Type |

Light |

Medium |

Heavy |

extra-heavy duty |

|

Material density /t·m |

0.8~1.2 |

>1.2~2.0 |

>2.0~2.8 |

>2.8 |

|

Weight to material ratio |

0.75~0.8 |

0.9~1.0 |

1.2~1.4 |

1.5~1.6 |

|

Adaptive material |

Medium coal, coke, slag, cement |

Limestone, bulk coal, peat, sand in water, sheet iron oxide |

Iron ore, powdery ore, heavy clay, rod columnar oxide iron sheet |

Bulk ore, bulk manganese ore stone |

Pycnometer of Loose Material Piles

Material name |

Proportion(t/m3) |

Material name |

Proportion(t/m3) |

Material name |

Proportion(t/m3) |

Material name |

Proportion(t/m3) |

|

Anthracite |

0.7-1.0 |

Zinc dust |

0.7-1.5 |

Pyrite (block) |

1.5-1.9 |

Large lime |

1.6-2.0 |

|

Bituminous coal |

0.8 |

Pyrite cinder |

1.7-1.8 |

Manganese |

1.7-1.9 |

Lime blocks

|

1.2-1.5 |

|

Lignite |

0.6-0.8 |

Lead and zinc pellets |

1.3-1.8 |

Magnesia (block) |

2.2-2.5 |

Small lime |

1.2-1.5 |

|

Peat |

0.29-0.5 |

Pyrite pellets |

1.2-1.4 |

Powdered magnesia |

2.1-2.2 |

Quicklime |

1.7-1.8 |

|

Peat (wet)) |

0.55-0.65 |

Flat slag (coarse) |

1.6-1.85 |

Copper |

1.7-2.1 |

Gravel |

1.32-2.0 |

|

Coke |

0.36-0.63 |

Blast furnace slag |

0.6-1.0 |

Copper concentrate |

1.3-1.8 |

Dolomite (block) |

1.2-2.0 |

|

Charcoal |

0.2-0.4 |

Lead and zinc water slag (wet) |

1.5-1.6 |

Lead concentrates |

1.9-2.4 |

Crushed dolomite |

1.8-1.9 |

|

Anthracite powder |

0.84-0.89 |

Dry ash |

0.64-0.72 |

Zinc concentrate |

1.3-1.7 |

Gravelly soil |

1.5-1.9 |

|

Bituminous coal powder |

0.4-0.7 |

Coal ash |

0.70 |

Lead and zinc |

1.3-2.4 |

Clay (small pieces) |

0.7-1.5 |

|

Powdered graphite |

0.45 |

Coarse sand (dry) |

1.4-1.9 |

Iron sinter |

1.7-2.0 |

Clay (wet) |

1.7 |

|

Magnetite |

2.5-3.5 |

Coarse sand (wet) |

1.4-1.65 |

Broken sinter |

1.4-1.6 |

Cement |

0.9-1.7 |

|

hematite |

2.0-2.8 |

Sand (wet) |

1.8-2.1 |

Lead Sintering |

1.8-2.2 |

Hydrated lime (powder) |

0.5 |

|

Limonite |

1.2-2.1 |

Molding sand |

0.8-1.3 |

Lead-zinc sintering block |

1.6-2.0 |

Hydrated lime |

2.0 |

Garbage grab overhead cranes

The Garbage Grab Overhead Crane is the heart of the garbage incineration plant feeding system; it is in charge of garbage feeding, handling, mixing, extracting, and weighing. Our company has always been at the top of the waste grab overhead crane market.

Beginning with the first non-drive transmitting cable drum, today's four-transducer hydraulic grab overhead crane ensures greater weight accuracy. While doing so, we continue to innovate and do research in order to keep up with the most cutting-edge technologies. So please contact us if you need any recommendations or technical assistance from our organization.

Steel scrape handling grab bucket crane

The material handling cranes used to load scrap into buckets are called grab bridge cranes for scrap handling. These scrap grab overhead cranes are made to handle heavy loads in difficult application conditions with a lot of noise, vibration, and dust. The scrap handling grab cranes used for transporting and sorting scrap from scrap yards to melt workshops are typically heavy-duty and high speed overhead cranes.

The primary consideration in the design of scrap cranes is safety. The scrap handling grab bucket overhead crane of Yuantai Crane is built with features of high efficiency and safety during the continuous operation inside the harsh environment of dusty, noisy, and others, etc., due to the lifting needs and challenging working conditions.

Biomass grab bucket overhead crane

A biomass crane is a grab overhead crane that is used to move materials from a biomass energy plant's reception pocket to storage, continuously feeding the combustion line. Since most factories only have one fully automated, unmanned grab bridge crane for this use, it needs to be reliable with no downtime.

Mining grab bucket crane

Grab bridge cranes are used in the mining industry to efficiently handle materials in the harsh environment while maintaining safety and preventing crane accidents. Lift and protect yourself with Dongqi Mining Industrial Cranes! No matter how tough the environment, safety and durability are assured.

double girder overhead crane with orange peal grab

double girder overhead crane with orange peal grab Open winch trolley for double girder grab bridge crane

Open winch trolley for double girder grab bridge crane