Check 5-ton overhead crane costs, key options & how features, duty class & industry use affect final price. Get latest 5 ton overhead crane for sale price!

Introduction of 5 Ton Overhead Crane Price

Overhead cranes with a 5 ton lifting capacity are some of the most commonly used equipment in industrial settings. Whether you run a small workshop, a fabrication shop, or a medium-sized factory, a 5 ton overhead crane usually fits the bill for most lifting and material handling tasks. It’s heavy enough to handle bulky loads but still manageable in terms of installation and maintenance.

But here’s the thing—when most buyers start looking at prices, they tend to think only about the sticker number. The truth is, the price of a 5 ton overhead crane is not just about the initial purchase cost. There are many factors that influence how much you will really spend. Things like the crane’s design, the type of hoist it uses, the controls, and even the supplier’s support can all impact the final cost.

What makes this guide different is that it shares real insights from people who have already been through the buying process. Experienced crane buyers have learned some important lessons, and they’re here to help you avoid common mistakes and make smarter decisions. Understanding what influences the price and what to look out for can save you both money and headaches down the road.

![5t overhead crane supplied to Panama in 2022]()

5t overhead crane supplied to Panama in 2022 - more about 5 ton ton single girder overhead crane types and specifications

Common Price Ranges for 5 Ton Overhead Cranes

When it comes to 5 ton overhead cranes, prices can vary quite a bit. Why? Because there are different types of cranes, features, and specs that all add up differently. Knowing the typical price ranges can give you a solid starting point and help you budget realistically.

Typical Price Brackets for Single Girder and Double Girder Cranes

- 5 Ton Single Girder Overhead Crane

These are usually the more economical choice. Single girder cranes have one main beam that supports the hoist. They are lighter, easier to install, and often cost less upfront. On average, a 5 ton single girder crane might cost somewhere between $7,000 and $15,000, depending on specifications and region.

- 5 Ton Double Girder Overhead Crane

Double girder cranes have two main beams, which makes them stronger and more stable. This design is preferred for heavy-duty or frequent lifting and longer spans. Naturally, they cost more—typically between $15,000 and $30,000 or more. The price increase is mostly because of extra steel, stronger components, and more complex engineering.

How Features and Specifications Influence Pricing

The price doesn’t just depend on the girder type. Several features can push the cost up or down:

- Span length and lifting height: Longer spans require bigger girders and stronger support structures, raising costs. Taller lift heights may need longer wire ropes or stronger motors.

- Type of hoist: Electric wire rope hoists generally cost more than chain hoists but offer smoother operation and greater durability. Explosion-proof or special hoists add to the price.

- Control options: Basic wired pendants are standard and affordable, but radio remote controls or automation upgrades come with extra fees.

- Environmental requirements: If your crane needs to work outdoors or in hazardous areas, expect to pay more for weatherproof coatings, explosion-proof parts, or corrosion resistance.

- Customization: Any non-standard requests, like specialized hooks, multiple speeds, or integration with factory systems, can add to the price.

Summary of Market Price Examples

To put things in perspective, here are some typical price examples you might see in the market:

| Crane Type |

Typical Price Range |

Why Price Varies |

| 5 Ton Single Girder Crane |

$7,000 – $15,000 |

Basic specs, shorter spans, simple hoist |

| 5 Ton Double Girder Crane |

$15,000 – $30,000+ |

Longer spans, heavier duty, extra girder |

| 5 Ton Explosion-Proof Crane |

$20,000 – $35,000+ |

Special safety features for hazardous zones |

| 5 Ton Customized Crane |

$18,000 – $40,000+ |

Tailored designs, special controls, coatings |

Remember, these prices can fluctuate depending on supplier location, material costs, and demand. Getting several quotes with detailed breakdowns is always a smart move.

Lessons From Experienced Crane Buyers

When it comes to buying a 5 ton overhead crane, going for the lowest price might seem like a good idea at first. But experienced crane buyers quickly learn that this approach can sometimes backfire. The truth is, price alone doesn’t tell the whole story. There are many hidden factors that can make a “cheap” crane much more expensive in the long run.

Why the Lowest Price Can Be Misleading

- A low initial price might mean the crane is made with cheaper materials or less precise engineering.

- Some suppliers cut corners on important parts like the hoist, control system, or safety devices.

- After-sales service might be poor or non-existent, leaving you stuck if the crane breaks down.

- Installation costs and shipping fees may not be included upfront, leading to unexpected bills.

In other words, the “bargain” you get today could end up costing you a lot more in repairs, downtime, and replacement parts.

Real Stories of Buyers Who Faced Unexpected Costs or Problems

One buyer chose a very low-cost 5 ton single girder crane from an unknown supplier. At first, it seemed like a great deal. But soon after installation, the hoist started malfunctioning, and replacement parts were hard to find. The buyer had to pay extra to bring in a technician from far away and also faced several days of lost production.

Another factory owner went for a double girder crane without verifying the supplier’s certifications. When the crane was delivered, it didn’t meet the local safety standards, causing delays and extra costs for modifications and re-inspections.

These stories aren’t rare. They highlight why buying based on price alone is risky.

The Importance of Quality, Certifications, and Trusted Suppliers

- Quality: A crane built with solid materials and tested components will last longer and work more reliably.

- Certifications: Look for CE, ISO, or other relevant certifications that show the crane meets safety and performance standards.

- Trusted Suppliers: Choosing a supplier with a proven track record means better support, easier access to spare parts, and smoother installation.

Experienced buyers recommend spending time researching suppliers, checking reviews, and asking for detailed documentation before making a purchase.

![5 ton double girder overhea crane - more on 5 ton double girder overhead crane specifications and customized options]()

5 ton double girder overhea crane - more on 5 ton double girder overhead crane specifications and customized options

Choosing the Right Crane Type for Your Needs

Picking between a single girder and a double girder 5 ton overhead crane is one of the first decisions buyers face. Each type has its pros and cons, and the choice depends largely on your specific work environment and lifting requirements.

Single Girder vs. Double Girder: Cost and Application

Single Girder 5 Ton Crane:

- Usually more affordable upfront due to simpler design and less steel.

- Ideal for workshops or factories with shorter spans and lighter-duty cycles.

- Easier and quicker to install, which can save on labor costs.

- Limited lifting height because the hoist runs on top of the girder.

Double Girder 5 Ton Crane:

- More expensive because it uses two girders and heavier steel structures.

- Best for longer spans, heavier or more frequent lifting operations.

- Hoist runs between the girders, allowing higher lifting heights and better stability.

- Typically lasts longer under heavy-duty conditions, reducing downtime.

Why Matching Crane Type to Actual Needs Saves Money

Choosing a crane that fits your actual usage will prevent overspending on unnecessary capacity or features. For example, buying a double girder crane for light, occasional lifting tasks means paying more for strength you don’t need. On the other hand, selecting a single girder crane for heavy or frequent lifts might result in early wear or safety issues, leading to costly repairs or replacements.

Before deciding, carefully assess:

- The typical weight and size of loads.

- Frequency of lifts per day or week.

- Span length and lifting height requirements.

- Available workshop space and ceiling height.

A well-matched crane keeps your upfront costs reasonable and reduces maintenance expenses over time.

Customization and Its Impact on Price

Off-the-shelf cranes cover many general needs, but sometimes you need something more tailored. Customizations improve crane performance or safety but also add to the price. Knowing what options exist and how they affect costs helps you budget smarter.

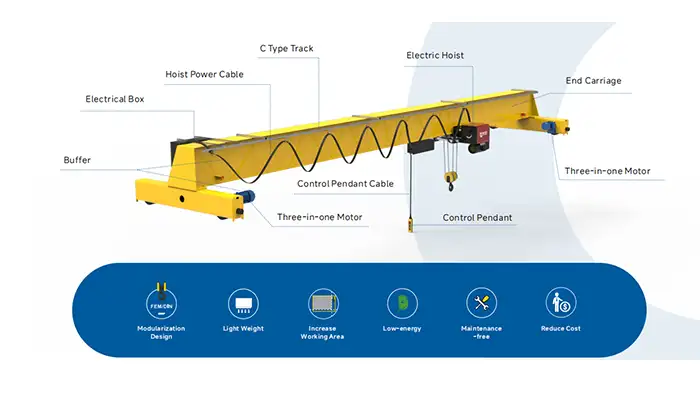

![single gider overhead crane 5 ton main component and features]()

Common Customizations That Affect Crane Price

Explosion-Proof Designs:

- Required in hazardous environments like chemical plants or oil refineries.

- Involves special motors, wiring, and enclosures to prevent sparks or fires.

- Adds a significant premium due to extra engineering and certification requirements.

Special Hoists:

- Magnetic or clamp hoists for handling specific materials like steel billets.

- Heavy-duty wire rope hoists for more frequent or rough lifting conditions.

- These hoists often cost more than standard electric chain hoists.

Longer Spans and Higher Lifting Heights:

- Requires stronger girders, longer wire ropes, and more powerful motors.

- Bigger structural components increase material and fabrication costs.

Advanced Control Systems:

- Radio remote controls or automation features improve safety and efficiency.

- These systems come at an extra cost for hardware and software integration.

Weatherproof Coatings and Materials:

- For outdoor or corrosive environments, special paints or stainless steel parts protect the crane.

- Adds cost but extends the crane’s service life.

Planning Ahead to Avoid Hidden Expenses

Custom features should be planned early. Last-minute changes or add-ons often lead to higher costs and delivery delays. Also, some customizations require special installation or ongoing maintenance — factor these into your budget.

Ask your supplier about:

- What customizations are necessary for your environment and usage.

- How these options impact delivery times and warranty coverage.

- Estimated maintenance costs for specialized parts.

Getting all this clear upfront will help you avoid surprises and make your 5 ton overhead crane investment worthwhile.

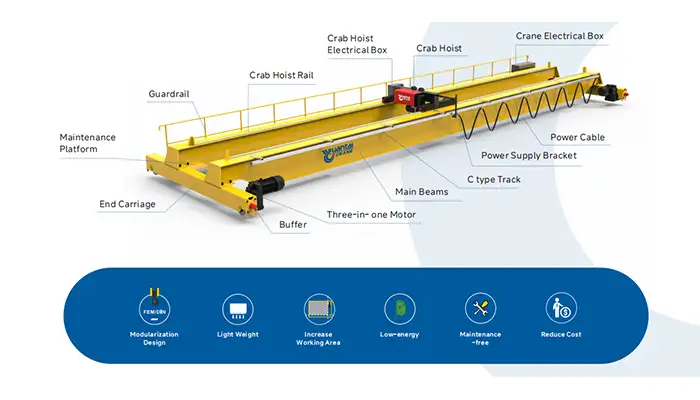

![double gider overhead crane 5 ton main component and features]()

Installation, Maintenance, and After-Sales Support Costs

Buying the crane is just the beginning. Installation and ongoing support play a huge role in how much your crane actually costs over its lifetime. Skipping over these factors can lead to headaches and unexpected expenses later.

Why Installation Fees and Setup Matter

- Proper installation ensures the crane works safely and efficiently right from day one.

- Installation costs vary depending on crane size, complexity, and site conditions.

- Some suppliers include installation in their quote; others charge separately — always clarify this upfront.

- Poor or rushed installation can cause equipment damage, safety risks, and costly downtime.

Getting experienced technicians who understand the specific crane model is crucial. Don’t try to cut costs by using untrained workers or ignoring installation guidelines.

The Role of Maintenance and Reliable Supplier Support in Total Ownership Cost

- Regular maintenance extends the crane’s life and prevents breakdowns.

- Some components like hoists, motors, and controls need periodic inspections and part replacements.

- Reliable suppliers offer training, spare parts availability, and responsive service teams.

- Without solid after-sales support, fixing issues can become expensive and time-consuming.

When comparing suppliers, ask about their maintenance packages, warranty terms, and how fast they can respond to service calls.

Total Cost of Ownership — Beyond the Initial Price

Looking at just the sticker price won’t give you the full picture. A crane’s real cost includes energy use, downtime, and repairs — all of which add up over the years.

Key Factors Affecting Long-Term Costs

Energy Efficiency:

- More efficient motors and controls use less power, saving money month after month.

- Variable frequency drives (VFDs) can reduce energy consumption during light loads.

Downtime Costs:

- Every hour your crane is down means lost productivity and potential delays.

- Investing in reliable cranes and preventive maintenance reduces downtime risks.

Spare Parts and Repairs:

- Availability and cost of parts impact repair expenses.

- Using quality parts prevents repeated breakdowns.

Why Investing More Upfront Often Saves Money Later

Spending a bit more initially on a well-built, efficient crane with good support can avoid expensive repairs and operational hiccups. It also protects worker safety and keeps your production running smoothly.

Practical Tips for New Buyers to Get the Best Value

If you’re new to buying overhead cranes — especially a 5 ton model — the process can be a bit overwhelming. There are technical terms, price ranges that vary wildly, and a lot of unfamiliar options. But don’t worry. With the right approach, you can avoid costly mistakes and get a crane that fits both your budget and your workshop’s needs.

Request Detailed and Transparent Quotes

One of the most common complaints from first-time buyers is that the initial quote didn’t reflect the final cost. That’s why it’s so important to ask for a complete breakdown.

- Request quotes that list all key components: hoist type, control system, end trucks, motor brands, etc.

- Confirm if the quote includes installation, shipping, and on-site adjustments — or if those are separate.

- Ask if the crane is factory-tested and comes with load test certification.

- Clarify the warranty period and whether spare parts are readily available.

A detailed quote helps you compare offers apples to apples and spot where extra costs may come in later.

Ask the Right Questions to Suppliers

Don’t just focus on the price — ask questions that help you understand what you’re really getting.

- What brand is the hoist, motor, and gearbox? Are they local or international?

- Can the crane be customized for my specific bay layout or ceiling height?

- What’s the lead time from order to delivery?

- Is on-site support available during installation and startup?

- Are there references or recent buyers I can contact?

A good supplier won’t hesitate to answer these. If they seem vague or avoid details, that’s a red flag.

Assess Your Real Lifting Needs Before Deciding

Before choosing between a 5 ton single girder crane and a double girder, or deciding whether to add automation or explosion-proof protection, take time to understand your own operations.

- What’s the actual weight of the loads you lift most often? Are they consistent or do they vary widely?

- How many lifts per hour/day? This affects crane duty classification and hoist type.

- Do you need high lifting height or long spans? That can determine if a double girder is worth the extra cost.

- Are you working indoors or outdoors, or in a dusty, hot, or corrosive environment?

Answering these questions early helps avoid overspending on unnecessary upgrades — or worse, underestimating what you need.

Final Tip: Don’t rush. A 5 ton overhead crane is a long-term investment. A little more time spent upfront understanding your requirements can save you thousands in the long run.

Conclusion: What You Should Take Away Before Buying a 5 Ton Overhead Crane

Balance Price, Performance, and Support — Not Just One

It’s tempting to pick the cheapest 5 ton crane on the list. But think about the long-term cost if it breaks down, wears out early, or can’t be upgraded later. A slightly higher upfront investment often gives you:

- More reliable performance

- Longer equipment lifespan

- Easier maintenance and part replacement

- Better safety for your operators

Remember: a crane should work for you, not create more problems to solve.

Ready to Move Forward? Let’s Help You Do It Right

If you’re serious about finding the right 5 ton bridge crane, workshop crane, or customized EOT crane setup — we’re here to help. Whether you need a basic 5 ton single girder crane or a more advanced explosion-proof or open-winch design, we’ll guide you based on real workshop needs, not just specs on paper.

Contact us today to get:

- A free consultation with an experienced crane engineer

- A detailed quotation tailored to your plant layout and lifting tasks

- Advice on how to reduce installation and maintenance costs

Let’s build a crane solution that fits your shop, your workload, and your budget — the right way from the start. Contact us today to get the latest 5 ton overhead crane for sale price!