Single girder explosion proof crane is a type of single girder overhead crane, designedfor hazardous environment, with features ofhigh safety,explosion proof, spark proof & flame proof. Get your exproofsingle girder overheadcrane now.

The LB explosion-proof single girder overhead crane was designed, manufactured, installed, and operated in accordance with the JB/T 10219 standard. The LB series of exploison proof crane is a light-duty crane compared with HB series of explosion-proof wire-rope electric hoist double girder overhead crane.

Advantages of single girder explosion proof crane

- Single girder design, simple structure, high rigidity.

- Good in use and easy to fabricate and manufacture

- Normal speed or frequency control, stable travelling and moving.

Explosion proof

- Explosion proof design to ensure safety in hazardous applications

- ExdIIBT4 or ExdIICT4 is the explosion-proof mark, and the temperature group is T1—T4 inflammable gas, explosive gas of steam and air mixture (reference to table I and II).

- Motors and other electrical components should be selected in accordance with the explosion class.

- Explosion-proof motor electrical parts should be manufactured and inspected in accordance with GB3836.2-2000.

Applications of explosion proof single girder overhead crane

Scope of supply of single girder explosion proof crane

Our company primarily manufactures explosion proof single girder overhead cranes with lifting capacities ranging from 1t to 20t, spans ranging from 7.5m to 28.5m, and lifting heights ranging from 1m to 30m. And the non-standard exproof cranes also can be designed and manufactured based on customer’s lifting requirements and crane specifications.

Working conditions:

The explosion proof crane is suitable for temperatures ranging from -25°C to +40°C, humidity levels of up to 85%, and altitudes of less than 1000m. Power supply is 3-phase 380v 50Hz (can be customized to meet the needs of the customer).

Applications

- According to JB/T 10219-2001 Explosion-Proof Overhead Crane to design、manufacture、installation and be applied to use.

- To be used with an explosion-proof hoist.

- Lifting and transporting goods is a common use in factories, warehouses, and other locations.

- When used in factories, the explosion transfer ability is limited to class IIB or IIIC.

- Features of single girder explosion proof crane

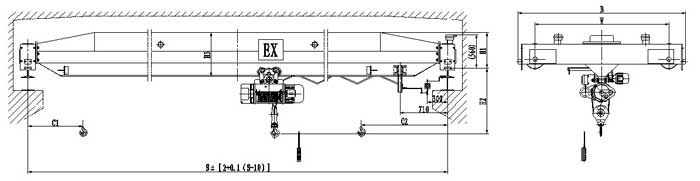

- Mainly composed of metal structure(main girder, end truck), explosion-proof electric wire rope hoist(lifting mechanism), traveling mechanism and electrical equipments.

Features of single girder explosion proof crane

The single girder explosion proof crane is mainly composed of metal structure(main girder, end truck), explosion-proof electric wire rope hoist(lifting mechanism), traveling mechanism and electrical equipment.And the main features of parts of exproof cranes are presented for your reference

Main girder

- The main girder of exproof crane is welded by a high-quality I-beam and one-time molding, stamping U-slots, or a steel plate of box beam.

- A polyurethane buffer is installed at each end of the overhead crane girder to ensure the safe travel of the explosion proof hoist.

End carriages

- The end truck or carriages of an explosion proof crane are welded together using a rectangular tube or a high-quality steel plate.

- The main girder and end carriages of an overhead crane are connected by a hanging panel or half-sit half-hang bolts, making it easy to assembly and transport.

Electric wire rope hoist that is explosion-proof

- Lifting mechanism, traveling mechanism, and electrical parts are the main components.

- Lifting motor, reducer, drum, coupling, wire rope, hook, and other components make up the majority of the system.

Lifting motor

- .Adapts a whole sealing tapered rotor asynchronous motor, specially made from the explosion-proof motor series, which causes the explosion-proof hoist to stop in a short period of time when the motor is cut off the power.

- The insulation class is either B or F, and the motor protection class is IP44/IP54.

- The explosion-proof shell is made of cast iron HT200, and after processing, it is subjected to a one-minute 1105pa hydrostatic test to ensure safety.

Control ways

- Ground control and cabin control are optional for your single girder explosion proof crane. Electrical control box, controlling button, position limiter are all explosion-proof to ensure safety.