A single girder semi-gantry crane is a type of economical gantry crane that has only one single supporting leg. The single girder gantry crane with semi wall travelling on height & semi rail travelling on the ground with single supporting outriger. They are perfect for offering material handling solutions at work sites where space is limited due to machinery, narrow spacing, or confined spaces. And also, they are extensively used both inside and outside of warehouses, material yards, and workshops, among other places. What’s more, a semi gantry crane with single leg design has the benefit of being able to be installed beneath existing overhead bridge cranes to help complete material handling.

BMH Single Girder Semi Portal Crane

The BMH single girder semi portable crane is a type of economical gantry crane, which is designed with typical u shaped box girder and I beam girder, equipped with CD/MD electric wire rope hoists for loads handling with capacity from 1 ton to 20 ton.

Technical parameter of BMH single girder semi gantry crane

|

Model |

AQ-BMH |

|

Load capacity |

3-20t |

|

Span |

8-30m |

|

Lifting height |

6-18m |

|

Lifting speed |

0.33-8m/min |

|

Trolley running speed |

20m/min |

|

Crane running speed |

20m/min |

|

Work duty |

A3, A4 |

Features of BMH sinngle girder semi gantry cranes

- SWL capacity of single girder semi gantry crane is up to 20 tons

- Simple structure and s imple assembly

- Low initial investment expenses

- Minimal structural stress

BMHO single girder semi gantry crane with single leg design & European style

The European style single girder semi gantry crane is designed with European style box shaped girder and low headroom wire rope hoists, which are typically used in low headroom application and can save your workshop facility construction cost.

Technical parameters of BMHO European style single girder semi gantry crane design

|

Model |

BMHO European Type |

|

Load capacity |

3.2-20t |

|

Span |

8-30m |

|

Lifting height |

6-18m |

|

Lifting speed |

0.66-5m/min |

|

Trolley running speed |

2-20m/min |

|

Crane running speed |

3-30m/min |

|

Work duty |

A5 |

European Style Semi-Gantry Crane with single girder design

- European style electric wire rope hoist with low headroom design

- Optimized main beam design, reduced wheel pressure, and light weight

- Three-in-one drive system with frequency conversion and stepless speed control

- Longer service life, improved look, and a more compact structure

Applications Of Semi Gantry Cranes

The single girder semi gantry cranes are commonly used in mechanical processing workshops, open areas, and warehouses for material handling. It can be placed beneath an existing large overhead crane to increase work productivity while not interfering with the overhead material handling operation.

2 Ton Semi Gantry Crane for indoor use in machine shop, installed under the overhead bridge crane system.

3 Ton Semi Gantry Cranes for indoor use in workshops for various loads handling with overhead travelling bridge cranes.

Economical electric hoist single girder semi gantry crane 3 ton for outdoor use

Outdoor use semi gantry crane 5 ton with single leg and freestanding supporting runways which are used when your facility is not possible to support the weights of crane and loads

Advantages of single girder semi gantry cranes

- Structure is compact and solid.

- Favorable performance, smooth starting and stopping, safe and reliable travel, and powerful lateral load proofing ability.

- There is little commotion and no pollution.

- Flexible installation and operation, simple upkeep, energy savings.

- Excellent exchange ability for parts and components.

BMH(O) Semi Gantry Crane Structure

What is a semi gantry crane? A semi-gantry crane is a variation of overhead bridge crane, which is designed with one end of the main girder supported by freestanding gantry leg and other end travelling along ruway beam supported by facility walls on the height. The main structure of the single leg gantry cranes is made of crane bridges, the crane running mechanism, the trolley running mechanism, and the hoisting mechanism, and electric systems, etc.

Depending on your lifting needs, our semi-gantry cranes can be configured with a single or double girder design, with European style low headroom hoists and economical cd/md wire rope hoists, etc. Compared with normal use full gantry crane, the single girder portal gantry crane is a good choice to save investment and space.

If you are interested in our semi single leg portal gantry cranes, please to contact us to determine the best gantry crane solution for your facility!

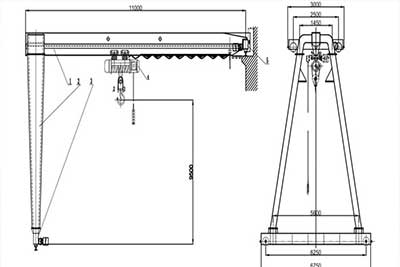

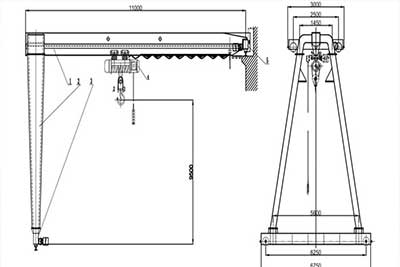

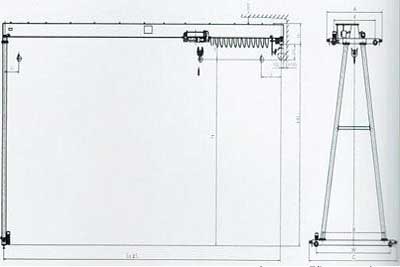

CD/MD electric hoist single girder semi gantry crane drawing

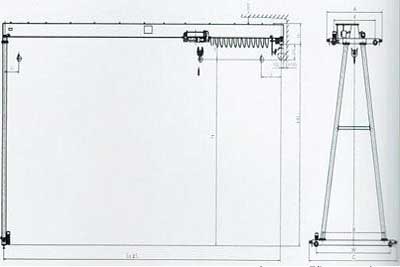

ND low headroom rope hoist single girder semi portal gantry crane drawing

BMH Semi Gantry Crane

BMHO Semi Gantry Crane

The wire rope electric hoist model CD1,MD1 , which can be designed with single speed, double speed, and variable speed.

European style wire rope hoist single girder design , light and compact structure, variable speed, and low headroom design,

Main Beam : The main girder will be sandblasted and painted with a zinc-rich epoxy primer. Plasma numerical control cutting equipment is used to cut the main beam. The tension flange butt weld shall be subjected to ultrasonic or x-ray flaw identification as stated.

Outrigger All connection locations are linked by a high-tension bolt and consist of rigid and flexible outriggers. The ladder is used by the operator to access the cab or to arrive at the winch. When the span exceeds 30m, a flexible leg is required to minimize the lateral thrust of the trolley to the rail when the girder lifts materials.

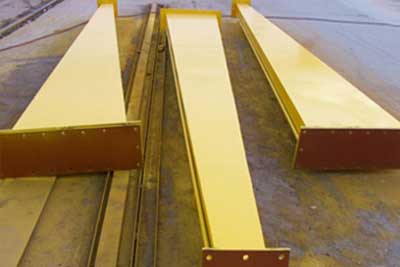

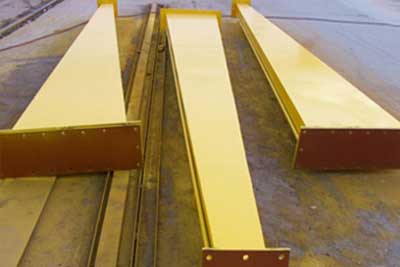

Ground End Beam: The end beam will be sandblasted and coated with a zinc-rich epoxy primer. End beam wheels are manufactured in a unique vacuum casting workshop, which makes the wheels more elastic and the outer surface hard-wearing and durable.

Features of Yuantai ’ s semi gantry cranes

- Overload protection: If the material weight surpasses the rated capacity, the gantry crane will emit a loud warning to ensure overloading will not happen and ensure safety.

- Emergency brake: If the management staff encounters an emergency, we can activate the emergency brake system.

- Control Method: Cab or remote control to protect the working personnel.

- The main lifting motor has thermal and currency safety.

- 5. When a danger occurs, the emergency switch can halt all motions.

- Stable & smooth travelling : A-frame supporting leg with stable running.

- High quality: All cranes must be ore-assembled and tested before leaving factory and offer the certification of test.

- Low & easy Maintenance: Excellent exchange ability for parts and components. Convenient maintenance, Electricity saving.

- The hoist can be a classic CDMD wire rope hoist or European standard wire rope hoist.

Semi Gantry Crane Design To Your Specs!

We provide custom single girder semi-gantry cranes for a variety of industrial sectors, including manufacturing and metallurgy.

All gantry crane designs and manufacturing processes closely adhere to national standards. And all of our gantry cranes are qualified, having been tested and examined by our expert crane inspection and testing equipment and engineering teams.

We have experienced engineers on hand to assist you in designing the best gantry crane system for your business.

To get your specific semi gantry crane design and crane price, the following information are required :

- – Load capacity: ton?

- – Span of the semi gantry crane: m?

- – Max. lifting height of the portal crane: m;

- – Traveling length if crane rail is required : m?

- – How many hours will the crane work per day? How many times per hour?

- – Electric Power supply: 3 phase 380V 50Hz?

- – What kind of material will the single leg crane lift?

2 Ton Semi Gantry Crane for indoor use in machine shop, installed under the overhead bridge crane system.

2 Ton Semi Gantry Crane for indoor use in machine shop, installed under the overhead bridge crane system. 3 Ton Semi Gantry Cranes for indoor use in workshops for various loads handling with overhead travelling bridge cranes.

3 Ton Semi Gantry Cranes for indoor use in workshops for various loads handling with overhead travelling bridge cranes. Economical electric hoist single girder semi gantry crane 3 ton for outdoor use

Economical electric hoist single girder semi gantry crane 3 ton for outdoor use Outdoor use semi gantry crane 5 ton with single leg and freestanding supporting runways which are used when your facility is not possible to support the weights of crane and loads

Outdoor use semi gantry crane 5 ton with single leg and freestanding supporting runways which are used when your facility is not possible to support the weights of crane and loads CD/MD electric hoist single girder semi gantry crane drawing

CD/MD electric hoist single girder semi gantry crane drawing  ND low headroom rope hoist single girder semi portal gantry crane drawing

ND low headroom rope hoist single girder semi portal gantry crane drawing BMH Semi Gantry Crane

BMH Semi Gantry Crane The wire rope electric hoist model CD1,MD1 , which can be designed with single speed, double speed, and variable speed.

The wire rope electric hoist model CD1,MD1 , which can be designed with single speed, double speed, and variable speed. European style wire rope hoist single girder design , light and compact structure, variable speed, and low headroom design,

European style wire rope hoist single girder design , light and compact structure, variable speed, and low headroom design, Main Beam : The main girder will be sandblasted and painted with a zinc-rich epoxy primer. Plasma numerical control cutting equipment is used to cut the main beam. The tension flange butt weld shall be subjected to ultrasonic or x-ray flaw identification as stated.

Main Beam : The main girder will be sandblasted and painted with a zinc-rich epoxy primer. Plasma numerical control cutting equipment is used to cut the main beam. The tension flange butt weld shall be subjected to ultrasonic or x-ray flaw identification as stated. Outrigger All connection locations are linked by a high-tension bolt and consist of rigid and flexible outriggers. The ladder is used by the operator to access the cab or to arrive at the winch. When the span exceeds 30m, a flexible leg is required to minimize the lateral thrust of the trolley to the rail when the girder lifts materials.

Outrigger All connection locations are linked by a high-tension bolt and consist of rigid and flexible outriggers. The ladder is used by the operator to access the cab or to arrive at the winch. When the span exceeds 30m, a flexible leg is required to minimize the lateral thrust of the trolley to the rail when the girder lifts materials. Ground End Beam: The end beam will be sandblasted and coated with a zinc-rich epoxy primer. End beam wheels are manufactured in a unique vacuum casting workshop, which makes the wheels more elastic and the outer surface hard-wearing and durable.

Ground End Beam: The end beam will be sandblasted and coated with a zinc-rich epoxy primer. End beam wheels are manufactured in a unique vacuum casting workshop, which makes the wheels more elastic and the outer surface hard-wearing and durable.