Overhead Cranes for Automotive Assembly, Hot Sale 10 Ton, 20 Ton

Overhead cranes for automotive assembly, including overhead bridge crane, gantry crane, jib crane with different designs & configurations, hot sale 5, 10, 20 ton.

Elevating Efficiency: Unveiling the Power of Overhead Cranes

In the world of automotive assembly, efficiency reigns supreme. The race to produce vehicles that meet stringent quality standards and customer demands requires precision, speed, and reliability. Enter the unsung heroes of the assembly line: overhead cranes. These mechanical marvels take center stage, elevating efficiency in ways you may have never imagined. Join us on a journey as we unveil the power of overhead cranes and explore how they are revolutionizing automotive assembly.

Types of Overhead Cranes: Precision in Motion

In the intricate world of automotive assembly, precision and control are paramount. Overhead cranes, available in various types, are the backbone of this precision. Let's delve into these remarkable machines, highlighting their distinctive features, advantages, and the roles they play in the assembly process.

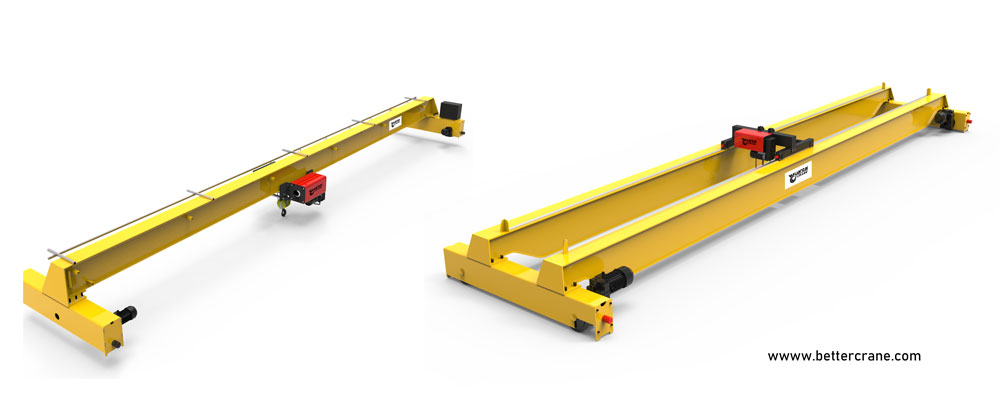

Bridge Cranes (Overhead Traveling Cranes):

- Bridging the Gap: Features that Set Bridge Cranes Apart: Bridge cranes, with their horizontal bridge (single or double girder) that traverses parallel runways, are renowned for their ability to lift, transport, and position hefty components. With high load capacity and precise positioning, they are the workhorses of the assembly line.

Soaring Benefits: Why Bridge Cranes Excel: Imagine the efficiency of effortlessly moving large, unwieldy components, ensuring a seamless flow of materials. Bridge cranes do this and more, streamlining operations and reducing the risk of material damage. - On the Move: Bridge Cranes in Automotive Assembly: Bridge cranes are on the move, transporting stamped metal sheets, loading stamping presses, and carefully positioning components. Their versatility makes them indispensable in the world of automotive assembly.

Floor jib crane

Floor jib crane  Wall jib crane

Wall jib crane Jib Cranes:

- Pivotal Precision: Features of Jib Cranes: Jib cranes, with their vertical mast and horizontal boom, are designed for precision in localized lifting. They come in floor-mounted or wall-mounted varieties, allowing for flexibility in positioning.

- Swinging Success: The Advantages of Jib Cranes: Localized material handling is a breeze with jib cranes. Their compact design and precise control make them ideal for maneuvering subassemblies and handling smaller components with finesse.

- Jib Cranes in Action: Enhancing Assembly Efficiency: Witness jib cranes in action as they position components, assist assembly line workers, and handle the intricate tasks that demand precision and control.

single girder gantry crane

single girder gantry crane  double girder gantry crane

double girder gantry crane Gantry Cranes:

- Gantry Cranes: Features That Command Attention: Gantry cranes, reminiscent of bridge cranes but supported by sturdy legs on wheels or rails, are known for their versatility, high load capacity, and lateral movement capability.

- Gantry Greatness: Advantages in Heavy Lifting: From loading/unloading materials from trucks to positioning substantial components, gantry cranes take on the heaviest of lifting tasks. Their adaptability shines in the assembly plant.

- Gantry Cranes: The Driving Force in Assembly: Discover how gantry cranes drive efficiency, offering the perfect blend of power, precision, and mobility within the automotive assembly landscape.

These are the first steps of our journey into the world of overhead cranes in automotive assembly. Join us in the next installment as we explore how these machines are transforming the automotive industry, one precise movement at a time. Stay tuned!

Overhead Crane Capacilty, Designs and Configurations

In automotive assembly plants, overhead cranes, gantry cranes, and jib cranes come in various tonnages to meet the diverse needs of material handling. Here are the typical tonnages and main designs/configurations for each type of crane:

Here are typical overhead crane designs and configurations for different tonnages of overhead cranes, gantry cranes, and jib cranes used in automotive assembly plants:

Overhead Cranes:

2-Ton Overhead Cranes:

Design: Single girder bridge cranes with a compact and lightweight design.

Configuration: Often used for precise handling of smaller components and parts. Ideal for assembly line tasks that require agility and precision.

5-Ton Overhead Cranes:

Design: Can be single girder or double girder bridge cranes, providing versatility and stability.

Configuration: Used for a wide range of components, suitable for various assembly line layouts and tasks.

10-Ton Overhead Cranes:

Design: Typically double girder bridge cranes with a robust structure.

Configuration: Ideal for lifting and moving heavier components like vehicle bodies and larger subassemblies. Ensures precise and safe handling.

15-Ton Overhead Cranes:

Design: Similar to 10-ton cranes, often double girder bridge cranes.

Configuration: Used for large and heavy components, such as heavy-duty chassis frames and oversized vehicle bodies.

20-Ton Overhead Cranes:

Design: Double girder bridge cranes with reinforced structures for extreme lifting capacity.

Configuration: Reserved for the heaviest components, including large chassis structures for heavy-duty trucks.

Gantry Cranes:

2-Ton Gantry Cranes:

Design: Lightweight and portable gantry cranes with adjustable heights and spans.

Configuration: Versatile for various assembly tasks and can be easily relocated within the plant.

5-Ton Gantry Cranes:

Design: Mobile or fixed gantry cranes with increased lifting capacity.

Configuration: Suitable for handling larger and heavier components, with mobility options to adapt to the plant's layout.

10-Ton Gantry Cranes:

Design: Robust gantry cranes designed for heavy-duty lifting.

Configuration: Available in both mobile and fixed configurations, capable of handling substantial loads.

15-Ton Gantry Cranes:

Design: Sturdy and heavy-duty gantry cranes with multiple mobility options.

Configuration: Designed for heavy lifting and ideal for handling large and oversized components.

20-Ton Gantry Cranes:

Design: Gantry cranes with substantial lifting capacity and stability.

Configuration: Suitable for lifting and moving extremely heavy loads within the assembly plant.

Jib Cranes:

1-Ton Jib Cranes:

Design: Compact and lightweight jib cranes with a single mast.

Configuration: Ideal for localized material handling within a limited area.

2-Ton Jib Cranes:

Design: Jib cranes with increased lifting capacity while maintaining flexibility.

Configuration: Suitable for precise handling of various components within a moderate workspace.

3-Ton Jib Cranes:

Design: Often equipped with a sturdier mast and arm.

Configuration: Offers the flexibility to reach multiple workstations for handling heavier components.

5-Ton Jib Cranes:

Design: Robust jib cranes designed for versatility and durability.

Configuration: Capable of handling a wide range of components in automotive assembly.

10-Ton Jib Cranes:

Design: Heavy-duty jib cranes with a robust structure.

Configuration: Used for efficient localized material handling of heavier components.

These designs and configurations cater to the specific tonnages and requirements of material handling in automotive assembly plants, ensuring efficiency, safety, and precision in the assembly process. If you need custom design, please feel free to contact us.

Transforming Automotive Assembly: Overhead Cranes in Action

In the Automotive Assembly Industry: "Driving Precision: Overhead Cranes in Automotive Assembly

The heartbeat of the automotive assembly industry reverberates with precision, efficiency, and innovation. At the core of this dynamic sector lies a technological marvel that not only streamlines operations but also raises the bar for quality and productivity: overhead cranes. In this section, we explore how these engineering marvels are driving precision and reshaping the landscape of automotive assembly.

Driving Precision: Overhead Cranes in Automotive Assembly

Imagine a symphony where every note is perfectly timed, every instrument is in harmony, and the result is a masterpiece of engineering. That's what overhead cranes bring to the automotive assembly industry. Their role is nothing short of transformative, and here's how they achieve it:

- 1. Streamlined Material Handling: Automotive assembly demands the orchestration of numerous components, from engine blocks to chassis frames. Overhead cranes conduct this symphony by lifting, transporting, and positioning these components with unmatched precision. They ensure a seamless flow of materials from one station to another, reducing bottlenecks and optimizing the assembly line.

- 2. Efficiency Unleashed: In the high-speed world of automotive production, efficiency is the name of the game. Overhead cranes enhance efficiency by reducing manual labor, minimizing the risk of damage to components, and eliminating delays. With the press of a button, they swiftly and safely move heavy loads, contributing to faster production rates.

- 3. Safety First: Safety is non-negotiable in the automotive assembly process. Overhead cranes contribute to a safer work environment by minimizing the need for manual lifting and handling of heavy components. Equipped with safety features such as load limiters and anti-sway systems, these cranes are engineered with the well-being of workers in mind.

- 4. Precision Matters: Precision is the linchpin of quality in automotive assembly. Overhead cranes provide the means to position components with pinpoint accuracy. Whether it's aligning an engine block or delicately placing an intricate subassembly, these cranes ensure that every piece fits seamlessly into the automotive puzzle.

- 5. Space Optimization: In bustling assembly plants, space is a valuable commodity. Overhead cranes operate above the assembly line, making efficient use of vertical space while freeing up precious floor space below. This intelligent use of space allows for better organization and flow within the plant.

- 6. Versatile Workhorses: Automotive assembly plants are dynamic environments with diverse material handling needs. Overhead cranes rise to the occasion, adapting to various tasks and challenges. Whether it's loading/unloading materials, positioning components, or conducting quality inspections, they prove their versatility at every turn.

As we delve deeper into the world of automotive assembly, it becomes evident that overhead cranes are not mere machines; they are catalysts for progress. They enable precision, enhance safety, and empower efficiency, driving the automotive assembly industry toward ever-greater heights of quality and innovation. Stay with us as we continue to unveil the remarkable capabilities of these engineering marvels. The journey has only just begun.

Elevating Concerns: Safety, Maintenance, Compliance, and More

In the world of overhead cranes, precision and power meet safety and responsibility. As we navigate through the intricate landscape of automotive assembly, it's crucial to address the concerns that elevate the role of overhead cranes. These concerns encompass safety, maintenance, compliance with regulations, operator training, adaptability to diverse environments, and seamless integration within the assembly line ecosystem.

Safety: "Above All, Safety First: Overhead Crane Operation

Safety is not just a priority; it's a commitment. When it comes to overhead crane operation, safety takes center stage. In this section, we delve deep into the safety measures and protocols that ensure the well-being of workers, the protection of materials, and the prevention of accidents. Discover how overhead cranes are engineered with safety in mind, equipped with features like load limiters, anti-sway systems, and emergency stop buttons to keep operations secure.

Maintenance: "Upkeep Excellence: Ensuring Crane Reliability

Like any finely tuned machine, overhead cranes require regular maintenance to perform at their best. Upkeep excellence is the key to ensuring crane reliability. In this segment, we explore the importance of routine inspections, preventive maintenance, and swift repairs. Discover how proactive maintenance practices minimize downtime and extend the lifespan of these essential workhorses.

Compliance: "Compliance Commitment: Meeting Regulatory Standards

Rules and regulations ensure that operations run smoothly and safely. Overhead cranes are no exception. In this section, we delve into the world of compliance, where overhead cranes meet and often exceed industry and government standards. Learn how these machines adhere to regulations set by authorities such as OSHA and ANSI, ensuring that automotive assembly remains in compliance.

Operator Training: "Skilled Skies: Training for Crane Operators

Behind every smoothly operating crane is a skilled operator. Training for crane operators is a fundamental aspect of safety and efficiency. Discover the rigorous training programs that crane operators undergo to master the art of precise and safe crane operation. We'll also touch on the importance of certification, ensuring that operators are fully equipped to handle these powerful tools.

Environmental Adaptability: "Adapting to the Environment: Cranes in Varied Conditions

Not all assembly environments are the same, and overhead cranes must adapt to diverse conditions. Whether it's extreme temperatures, humidity, or cleanliness requirements, overhead cranes are engineered to thrive in various environments. This section explores how these cranes adapt and excel, ensuring they perform optimally regardless of the setting.

Integration: "Seamless Harmony: Cranes in the Assembly Line Ecosystem

The modern automotive assembly process is a well-orchestrated symphony of machinery, and overhead cranes play a crucial role in this harmonious ecosystem. We delve into how these cranes seamlessly integrate with assembly lines and other material handling equipment. Discover how they facilitate the smooth flow of components and vehicles within the plant, ensuring a synchronized production process.

In the world of overhead cranes, addressing these concerns is not a choice but a responsibility. As we navigate through safety, maintenance, compliance, training, adaptability, and integration, we gain a deeper appreciation for the meticulous engineering and dedication that go into ensuring the excellence of overhead cranes in automotive assembly. These concerns are not barriers; they are stepping stones to a safer, more efficient, and more sustainable future. Join us as we continue to explore the world of overhead cranes and their remarkable contributions.

Frequently Asked Questions (FAQs) on Overhead Cranes: Answers to Your Queries

Have questions about overhead cranes and their role in automotive assembly? You're not alone. We've gathered the most frequently asked questions to provide you with clear, concise answers that shed light on these powerful machines and their applications.

Q1. What are the key features that differentiate bridge cranes from other types?

Bridge Cranes Unveiled: Features That Define Excellence: Bridge cranes are the workhorses of overhead cranes, but what sets them apart? In this FAQ, we explore the distinctive features that make bridge cranes stand out in the world of material handling.

Q2. How do jib cranes contribute to localized material handling?

Jib Cranes: Masters of Precision in Localization: Jib cranes excel in localized material handling tasks. Discover how their unique design and precise control make them masters in the art of handling smaller components with finesse.

Q3. What are the safety features integrated into our overhead cranes?

Safety Elevated: A Closer Look at Crane Safety Features: Safety is paramount in crane operation. This FAQ takes a closer look at the safety features integrated into overhead cranes, ensuring that every lift is a secure one.

Q4. How can operators ensure precision when using overhead cranes for component placement?

Precision Matters: Tips for Accurate Component Placement: Precision is the key to quality in automotive assembly. Learn valuable tips for operators to ensure that components are placed with accuracy and finesse.

Q5. What are the environmental considerations when selecting overhead cranes for automotive assembly?

Eco-Friendly Elevation: Cranes in Automotive Assembly Environments: In today's world, environmental considerations are paramount. Discover how overhead cranes are designed to adapt to diverse environmental conditions, contributing to a sustainable automotive assembly process.

These FAQs provide insights into the world of overhead cranes, addressing common queries and demystifying the technology that powers automotive assembly. Join us as we answer your questions and equip you with the knowledge you need to make informed decisions about these remarkable machines.

Conclusion: Your Guide to Making the Right Crane Choice

As our journey through the world of overhead cranes in automotive assembly comes to a close, we find ourselves equipped with a wealth of knowledge about these remarkable machines. We've explored their types, unraveled their features and benefits, witnessed their transformational role in the automotive industry, and addressed crucial concerns surrounding their use. Now, let's sum it all up and guide you toward making the right crane choice for your needs.

Overhead cranes are not mere tools; they are partners in progress. They elevate efficiency, drive precision, and ensure safety. They adapt to diverse environments and seamlessly integrate within assembly line ecosystems. But most importantly, they empower you to make the right choice, one that aligns with your specific requirements.

In this guide, you've discovered:

- The diverse types of overhead cranes, each with its unique features and applications.

How overhead cranes are transforming the automotive assembly industry, enhancing quality and productivity.

The paramount concerns of safety, maintenance, compliance, training, adaptability, and integration.

Answers to common questions about overhead cranes, shedding light on their capabilities.

As you embark on your journey to select the perfect overhead crane for your automotive assembly needs, remember that precision matters. The right crane can elevate your operations to new heights, ensuring that every component aligns perfectly, every process flows smoothly, and every vehicle meets the highest standards of quality and safety.

We invite you to explore the world of overhead cranes further, engage with experts, and seek the solutions that best suit your assembly plant. With the right crane by your side, you're not just building vehicles; you're building excellence. If you have any problem or need, please feel free to contact us by leaving a message dow below.