Aluminum Gantry Cranes: Sanitary Cranes for Beverage Production

Aluminum Gantry Cranes: Sanitary Cranes for Beverage Production

Sanitary Cranes for sale good price. Custom aluminum gantry crane for beverage production up to 5 ton for your beverage manufacturing plant. Contact us!

In beverage production, every step counts towards ensuring quality, efficiency, and hygiene. Among the unsung heroes of this industry are aluminum gantry cranes, often overlooked but crucial in maintaining sanitary conditions and streamlining operations. Let's delve into why these cranes are indispensable in beverage production.

Aluminum gantry cranes are sturdy yet lightweight lifting solutions that play a pivotal role in material handling within various industries. Their distinguishing feature lies in their construction material: aluminum. This choice offers a perfect balance between strength and portability, making them ideal for dynamic environments like beverage production facilities.

In the beverage industry, maintaining strict sanitary standards is non-negotiable. Any compromise in cleanliness can lead to contamination, jeopardizing product quality and consumer safety. This is where sanitary cranes, including aluminum gantry cranes, step in. They are designed with materials and features that prioritize hygiene, ensuring that the entire production process remains free from contaminants.

Sanitary cranes not only adhere to industry regulations but also go the extra mile in preventing microbial growth, corrosion, and other potential hazards. Their design minimizes crevices where dirt and debris can accumulate, making cleaning and sanitation procedures more effective and efficient.

By choosing aluminum gantry cranes specifically crafted for sanitary applications, beverage producers can uphold the highest standards of cleanliness throughout their operations. This not only safeguards the integrity of their products but also builds trust with consumers who prioritize quality and safety.

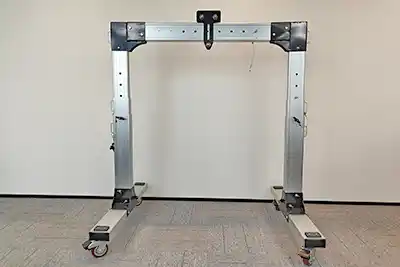

Types of Aluminum Gantry Cranes

Sanitary cranes are specially designed to meet the stringent hygiene requirements of industries like food and beverage production. These cranes feature smooth surfaces, rounded edges, and non-porous materials to minimize the risk of bacterial growth and facilitate easy cleaning. They often incorporate features such as stainless steel components, sealed bearings, and protective coatings to withstand frequent washdowns and harsh cleaning agents.

In beverage production, where cleanliness is paramount, sanitary cranes play a crucial role in maintaining the integrity of the products. They ensure that no contaminants are introduced during the lifting and handling of materials, thus safeguarding the quality and safety of the beverages.

LT1: Aluminum Gantry Crane with Fixed Span and Height

- Capacity up to 5 tons.

- Span up to 4 meters.

- Max. height up to 5 meters

Get Fixed Span & Fixed Hight Aluminum Alloy Gantry Crane Price

lT 2 Height Adjustable Aluminum Gantry Cranes

- Capacity up to 5 tons.

- Span up to 4 meters.

- Max. height up to 5 meters

LT3: Fixed Aluminum Gantry Crane with Adjustable Span and Height

- Capacity up to 2 tons.

- Span up to 4 meters.

- Max. height up to 4 meters

lT4 Simple Gantry Cranes with adjustable Height & Span

- Capacity up to 2 tons.

- Span up to 4 meters.

- Max. height up to 4 meters

LT5:Foldable Aluminum Gantry Crane with Adjustable Span and Height

- Capacity up to 3 tons.

- Span up to 4 meters.

- Max. lifting height is no more than 6 meters

LT6 Ajustable Gantry Crane with Telescoping Height and Span T Frame Gantry Cranes

- Capacity up to 2 tons.

- Span up to 4 meters.

- Max. lifting height is no more than 4 meters

Comparison with Traditional Cranes

Traditional cranes, while effective in many industrial applications, may not meet the strict hygiene standards required in food and beverage production. Unlike sanitary cranes, traditional cranes may have crevices, rough surfaces, and components made of materials that are prone to corrosion or contamination. These factors make them unsuitable for use in environments where cleanliness is paramount.

In contrast, sanitary cranes are purpose-built to address the unique challenges of sanitary applications. They are designed with features that minimize the risk of contamination and are constructed using materials that are resistant to corrosion and degradation from cleaning agents.

Advantages of Aluminum Gantry Cranes in Sanitary Applications

Aluminum gantry cranes offer several advantages in sanitary applications within beverage production facilities:

- Corrosion Resistance: Aluminum is inherently resistant to corrosion, making it an ideal choice for environments where frequent exposure to moisture and cleaning agents is unavoidable.

- Easy to Clean: The smooth surfaces and non-porous nature of aluminum gantry cranes facilitate easy cleaning and sanitation. This ensures thorough removal of dirt, debris, and potentially harmful microorganisms, reducing the risk of contamination.

- Portability: Aluminum gantry cranes are lightweight and portable, allowing for easy repositioning and deployment in different areas of the production facility as needed. This flexibility enhances efficiency and adaptability in handling various tasks.

- Durability: Despite their lightweight construction, aluminum gantry cranes are robust and durable, capable of withstanding the rigors of daily use in demanding industrial environments.

By investing in aluminum gantry cranes designed for sanitary applications, beverage producers can enhance operational efficiency, ensure product quality, and maintain compliance with regulatory standards. These cranes provide a reliable and hygienic lifting solution that is essential for the success of beverage production facilities.

Typical Loads Handled

- Bottles :Bottles are a primary packaging material used in beverage production, and their handling requires precision and care to prevent damage and contamination. Aluminum gantry cranes are equipped to lift and transport bottles safely and efficiently. However, the cylindrical shape and varying sizes of bottles pose specific challenges, such as the need for secure gripping mechanisms to prevent slippage during lifting.

- Cans :Cans are another common packaging format for beverages, valued for their convenience and portability. Like bottles, cans come in various sizes and may require specialized handling to ensure smooth and damage-free transportation. Aluminum gantry cranes equipped with adjustable lifting attachments can accommodate different can sizes and configurations, minimizing the risk of mishaps during lifting and movement.

- Beverage Ingredients :In addition to packaging materials, aluminum gantry cranes are also used to handle raw materials and ingredients used in beverage production. These may include sacks of sugar, barrels of flavorings, and containers of liquid additives. Each type of ingredient presents unique challenges, such as the need for proper containment to prevent spills and contamination. Sanitary cranes designed for food and beverage applications incorporate features to address these challenges, such as sealed bearings and corrosion-resistant materials.

- Packaging Materials :Apart from bottles and cans, beverage production involves handling various packaging materials such as cardboard boxes, plastic wrap, and pallets. Aluminum gantry cranes equipped with lifting attachments such as pallet forks or hooks can efficiently move these materials throughout the production facility. However, the lightweight nature of some packaging materials may require careful handling to prevent damage or distortion.

Specific Challenges Posed by Each Type of Load

- Bottles: The cylindrical shape of bottles can make them prone to rolling or tipping during lifting, requiring specialized lifting attachments or grippers to ensure stability.

- Cans: Cans come in different sizes and may be stacked or packed tightly, requiring precision lifting to prevent damage or distortion to the packaging.

- Beverage Ingredients: Some ingredients may be fragile or sensitive to rough handling, necessitating gentle lifting and movement to prevent spills or contamination.

- Packaging Materials: Lightweight packaging materials such as cardboard boxes or plastic wrap may be susceptible to tearing or damage if not handled carefully, requiring attention to lifting techniques and load distribution.

By understanding the specific challenges posed by each type of load, beverage producers can select the appropriate lifting equipment and ensure smooth and efficient material handling throughout the production process. Aluminum gantry cranes, with their versatility and reliability, play a vital role in overcoming these challenges and maintaining the integrity of the products.

Typical Crane Applications

Bottling Lines

- Overview of Bottling Process: Bottling lines are intricate systems designed for the efficient filling, capping, labeling, and packaging of beverages into bottles. These lines typically consist of multiple stages, including bottle cleaning, filling, sealing, and inspection, before the final packaging.

- Role of Gantry Cranes in Bottling Lines: Gantry cranes play a crucial role in various aspects of the bottling process. They are used for loading and unloading raw materials and packaging components, such as bottles, caps, and labels, onto the production line. Gantry cranes also assist in the movement of finished products from one stage of the line to another, ensuring smooth workflow and minimizing downtime.

Ingredient Handling

- Importance of Hygienic Handling in Food and Beverage Production: Hygienic handling of ingredients is paramount in food and beverage production to prevent contamination and ensure product safety. Any lapse in hygiene during ingredient handling can compromise the quality and integrity of the final product, leading to potential health risks for consumers.

- Role of Gantry Cranes in Ingredient Handling: Gantry cranes play a vital role in the hygienic handling of ingredients in beverage production facilities. They are used to lift, transport, and position raw materials and ingredients with precision and care. By utilizing sanitary cranes specifically designed for food and beverage applications, producers can maintain strict hygiene standards and minimize the risk of contamination throughout the ingredient handling process.

Hygienic Packaging

- Overview of Packaging Process: Packaging is the final stage of beverage production, where the finished products are carefully enclosed and sealed for distribution and consumption. This process involves various tasks, including grouping bottles or cans into packages, sealing them in cases or cartons, and labeling for identification.

- Importance of Maintaining Sanitary Conditions During Packaging: Maintaining sanitary conditions during the packaging process is essential to ensure the safety and quality of the packaged beverages. Any contamination introduced during packaging can compromise the integrity of the product and pose health risks to consumers. Therefore, strict adherence to hygiene protocols and the use of sanitary equipment are crucial in this stage of production.

- Role of Gantry Cranes in Hygienic Packaging Processes: Gantry cranes play a critical role in facilitating hygienic packaging processes by providing efficient and reliable material handling solutions. They are used to transport packaging materials, move finished products to packaging stations, and position containers for filling and sealing. By utilizing aluminum gantry cranes designed for sanitary applications, beverage producers can maintain the highest standards of cleanliness and ensure the integrity of their packaged products.

Typical Capacity Range

Crane capacity refers to the maximum weight that a crane can safely lift and transport. It is determined by various factors, including the crane's structural design, lifting mechanisms, and operational limitations. Understanding crane capacity is essential for ensuring safe and efficient material handling operations within beverage production facilities.

The typical capacity range for aluminum gantry cranes used in beverage production varies depending on the specific requirements of the application. However, these cranes typically have a capacity range of 0.5 to 5 tons. This range allows beverage producers to handle a wide variety of loads, including bottles, cans, packaging materials, and ingredients, with ease and efficiency.

Factors Influencing Capacity Selection

Several factors influence the selection of crane capacity for beverage production facilities:

- Type of Loads: The types of loads commonly handled in the facility, such as bottles, cans, ingredients, and packaging materials, dictate the required crane capacity. Heavier loads require cranes with higher capacities to ensure safe lifting and handling.

- Production Volume: The volume of production and the frequency of material handling operations impact the required crane capacity. Facilities with high production volumes may require cranes with higher capacities to accommodate the increased workload.

- Safety Considerations: Safety is paramount in beverage production facilities, and selecting a crane with an appropriate capacity ensures that lifting operations can be performed safely without exceeding the crane's limits.

- Space Constraints: The available space within the production facility may also influence crane capacity selection. Facilities with limited space may opt for smaller cranes with lower capacities to optimize space utilization while still meeting their material handling needs.

- Future Expansion: Consideration of future expansion plans is important when selecting crane capacity. Choosing a crane with a capacity that can accommodate potential growth in production volume ensures that the facility remains adaptable and scalable over time.

By carefully considering these factors, beverage producers can select aluminum gantry cranes with the appropriate capacity to meet their material handling requirements effectively and safely. This ensures smooth and efficient operations within the production facility while maintaining the integrity of the products being handled.

Conclusion: Custom Santitary Crane for Your Needs

Aluminum gantry cranes play a vital role in beverage production by providing reliable and efficient material handling solutions that meet the strict hygiene standards of the industry. From lifting bottles and cans to transporting ingredients and packaging materials, these cranes contribute to the smooth and safe operation of beverage production facilities. Their lightweight yet durable construction, coupled with features designed for sanitary applications, makes them indispensable assets in maintaining product quality and safety.

Types of Sanitary Cranes for Your Selections

When it comes to selecting sanitary cranes for various applications, there are several types to consider, each designed to meet specific needs in industries like food and beverage, pharmaceuticals, biotechnology, and cosmetics where cleanliness and hygiene are paramount. Here are some common types:

- Stainless Steel Bridge Cranes: These cranes are made entirely of stainless steel, including the hoist, trolley, and bridge. They are corrosion-resistant and suitable for environments where cleanliness is critical.

- Cleanroom Cranes: These cranes are designed for use in cleanroom environments where maintaining a sterile environment is essential. They typically feature smooth surfaces, sealed electrical components, and cleanroom-compatible lubricants.

- Explosion-Proof Cranes: In environments where flammable gases, vapors, or dust are present, explosion-proof cranes are necessary to prevent potential ignition sources. These cranes are designed to minimize the risk of explosions.

- Washdown Cranes: These cranes are designed to withstand frequent washdowns with water and cleaning agents. They often feature sealed components, corrosion-resistant materials, and smooth surfaces to facilitate cleaning.

- Corrosion-Resistant Cranes: In industries where exposure to corrosive substances is common, such as chemical processing or marine applications, corrosion-resistant cranes are essential. These cranes are typically made from materials like stainless steel or coated with corrosion-resistant finishes.

- Hygienic Cranes: Specifically designed for applications where cleanliness and sanitation are critical, hygienic cranes feature smooth surfaces, minimal crevices where dirt can accumulate, and are often compliant with stringent sanitation standards.

- Customized Solutions: Depending on the unique requirements of your industry and application, custom-designed sanitary cranes may be necessary. These can be tailored to meet specific needs regarding load capacity, environmental conditions, and regulatory compliance.

When selecting a sanitary crane, consider factors such as the specific requirements of your application, regulatory standards, environmental conditions, and budget constraints. Additionally, consulting with a knowledgeable crane manufacturer or supplier can help ensure you choose the right crane for your needs.

Summary of Key Points Discussed

Throughout this discussion, we have explored the significance of aluminum gantry cranes in beverage production:

- Sanitary Crane Design: We examined how sanitary cranes, including aluminum gantry cranes, are designed to meet the rigorous hygiene standards of the beverage industry, ensuring that products remain free from contamination.

- Versatile Handling: We discussed the versatility of aluminum gantry cranes in handling various loads, including bottles, cans, ingredients, and packaging materials, with precision and care.

- Crucial Applications: We highlighted the critical role of aluminum gantry cranes in key applications within beverage production, such as bottling lines, ingredient handling, and hygienic packaging processes.

- Capacity Considerations: We explored the typical capacity range of aluminum gantry cranes used in beverage production and the factors influencing capacity selection, emphasizing the importance of safety and efficiency.

As the beverage industry evolves and demands for higher quality and safety standards increase, aluminum gantry cranes will continue to evolve to meet these challenges. By staying abreast of the latest developments and embracing innovative solutions, beverage producers can optimize their operations and maintain a competitive edge in the market.

In conclusion, aluminum gantry cranes are indispensable assets in beverage production, ensuring the efficient and sanitary handling of materials from raw ingredients to finished products. Their role in maintaining product quality, safety, and efficiency cannot be overstated, making them essential components of modern beverage production facilities.