Case Study: Fixed Height Aluminum Gantry Crane 1 Ton – Philippines

Fixed Height Aluminum Gantry Crane

This case study looks at the successful export of two fixed-height aluminum gantry cranes to a customer in the Philippines. The client operates a light-duty service workshop and needed mobile lifting equipment for moving small machines, tools, and spare parts. The project involved careful coordination between our engineering, production, and export teams to ensure the cranes met the client’s needs for safety, simplicity, and portability.

Customer Location and Industry

- Location: Philippines

- Industry: Light equipment maintenance and workshop operations

- The client runs a small but busy workshop that handles regular equipment servicing and part assembly.

- They were looking for a compact lifting solution to handle occasional lifting tasks, especially when repositioning machines or components around their workspace.

- Mobility was not a major concern—they preferred fixed-height units that could be easily installed and left in place.

Fixed Height vs Adjustable Height Aluminum Gantry Cranes

Fixed Height vs Adjustable Height Aluminum Gantry CranesCrane Type and Specification

- Crane Model: LT1-1 Aluminum Gantry Crane

- Rated Load: 1 Ton per crane

- Span: 2000 mm (2 meters)

- Total Height: 2500 mm (2.5 meters)

- Design Type: Fixed-height frame, manual operation

- Quantity: 2 units

- Note: The client specifically requested the cranes without electric hoists, as they planned to use existing manual chain hoists.

- The cranes were constructed from lightweight but high-strength aluminum alloy, making them corrosion-resistant and easy to handle during setup.

Key Outcome

- Our team completed production on time and conducted full inspections before shipment.

- The cranes were tested for key parameters like span and height deviation, welding quality, and static load performance based on GB/T 14406 standards. All results met the required quality benchmarks.

- Packaging was customized to allow for safe and space-saving transport, using a knockdown structure that made assembly at the client’s site simple and efficient.

- After receiving the cranes, the client reported smooth installation and immediate use in their workshop.

- They were satisfied with the crane’s stability, finish, and overall ease of use.

In the end, this small project demonstrated how even basic lifting needs can be met with the right combination of design, material, and service. The client now has two reliable aluminum gantry cranes to support their day-to-day work.

Client Background

Country: Philippines

The client is based in the Philippines. Their workshop is located in an urban area with moderate humidity and limited indoor space, which made aluminum the ideal crane material.

Client Type: Maintenance Contractor

The customer runs a small maintenance service company. Their team provides repair and servicing for light equipment, tools, and workshop machinery. They mostly handle industrial support jobs—such as adjusting machines, moving motors, or lifting pumps.

They needed something practical. A big, complex crane wasn’t necessary. Their main concern was lifting safety and ease of use.

Application Scenario: Indoor Workshop Use

- The cranes will be used indoors in their service workshop.

- Daily tasks include lifting and relocating small machines during repair or part replacement.

- They also use the gantry crane to hold parts in position while their team works.

- The work area has a fixed ceiling height, so they needed a non-adjustable, fixed-height frame.

- Since the space is limited, they preferred a crane that could be moved in pieces and reassembled quickly.

In short, the aluminum gantry crane fit perfectly into their small-space, light-lifting environment. It gives them lifting support without taking up too much room or requiring complex installation.

Client Requirements

The client came to us with a clear set of needs. They had already used gantry cranes before, so they knew exactly what they were looking for. Their main goal was to have a simple, reliable lifting tool that fits their workshop space and workload.

Basic Specifications

- Load Capacity: 1 Ton

Enough to handle motors, pumps, and small equipment during maintenance. - Quantity: 2 Sets

One for each work zone in their facility. - Span: 2 meters

Compact enough for narrow areas but wide enough for common equipment sizes. - Total Height: 2.5 meters

Chosen to match their workshop’s ceiling height, leaving enough headroom for lifting.

Special Requests

The client also had a few specific requirements that we needed to follow closely:

- Fixed Height (Non-adjustable):

They didn’t need adjustable height. Fixed height makes the structure more stable and easier to set up. - No Electric Hoist Included:

They already had manual chain hoists on hand. They only needed the gantry frame. This helped them save cost and reduce shipping weight. - Lightweight and Portable Frame:

The frame had to be light enough for two workers to move and assemble without special tools. Aluminum alloy was the perfect material choice. - Easy Assembly/Disassembly:

The crane needed to be installed quickly and taken apart just as easily. This was especially important since they occasionally move workstations inside the shop.

In short, the client wanted something small, light, and practical—without any extra complexity. We made sure the crane matched all these points exactly.

Product Solution

To meet the client's specific needs, we supplied two sets of our LT1-1 Aluminum Gantry Crane. This model is designed for light-duty lifting tasks and works well in compact workshop spaces.

Model Provided: LT1-1 Aluminum Gantry Crane

The LT1-1 is a fixed-height, lightweight gantry crane built for easy setup and reliable performance. It’s a practical choice for service workshops, especially where mobility and quick installation matter.

Material: High-Strength Aluminum Alloy

The frame is made from durable aluminum alloy. It provides solid lifting capacity while remaining easy to carry and install. Aluminum is also naturally resistant to corrosion, which makes it well-suited for humid environments like the Philippines.

Key Features

- Fixed Height Design

The fixed height ensures a stable structure during lifting. There’s no need for adjustments, which makes the setup simpler and more secure. - Manual Hoist Compatibility

The gantry was designed without electric components so the client could use their existing manual chain hoists. - Lightweight and Portable

The crane can be handled by two people. This makes it easy to move between work zones or reposition when needed. - Easy Assembly and Disassembly

The crane comes in a knockdown form with bolted connections. The client can assemble it quickly using basic tools. This is helpful for maintenance teams that need to change layout from time to time.

Technical Specifications

- Rated Load: 1 Ton per crane

- Span: 2000 mm

- Total Height: 2500 mm

- Quantity: 2 units

- Hoists: Not included (as requested by client)

- Casters: Not included; the client planned for stationary use

This product solution gave the client exactly what they needed—simple, stable, and easy-to-use lifting equipment that matched their workshop conditions and work routine.

main girder of aluminum gantry crane

main girder of aluminum gantry crane main girder of aluminum gantry crane

main girder of aluminum gantry crane Supporting leg of small aluminum gantry crane

Supporting leg of small aluminum gantry crane ground beam with castors of aluminum gantry crane

ground beam with castors of aluminum gantry craneProduction and Quality Assurance

Manufacturing Lead Time

The production of both gantry cranes was completed within 15 working days. This included material preparation, fabrication, surface treatment, and final inspection. Since the structure was simple and standardized, the production process went smoothly without delays.

Key Inspection Items

Before delivery, a full quality check was done to make sure everything met the required standards. The following items were inspected:

- Span Deviation

Measured to confirm the gantry width stayed within the allowable tolerance. - Height Deviation

Checked to ensure the total height matched the fixed 2.5-meter requirement. - Welding Quality

Visual inspection for any defects such as cracks, porosity, undercut, or incomplete welds. - Lift Height Accuracy

Tested with a manual hoist to ensure the crane could safely support full lifting height.

Standards Followed

All inspections and measurements were done according to GB/T 14406, the national standard for general-purpose gantry cranes in China. This ensured all mechanical and structural aspects were within safe and acceptable limits.

Testing Equipment Used

To carry out the checks, we used:

- A manual chain hoist (to simulate real use)

- A load sensor (to measure applied weight and confirm load capacity)

Final Inspection Results

All inspection points passed.

- Span and height were within the required tolerances.

- No welding defects were found.

- The crane frame handled the test load without deformation or instability.

Both units were approved for shipment after final quality clearance.

1 Ton Aluminum Gantry Crane for Sale Philippines

1 Ton Aluminum Gantry Crane for Sale Philippines 1 Ton Aluminum Gantry Crane for Delivery to The Philippines

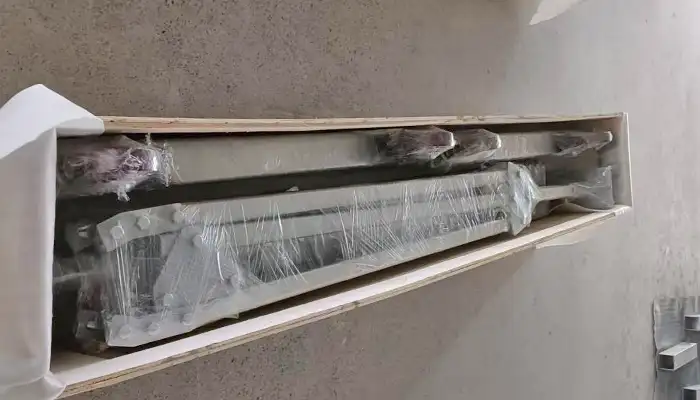

1 Ton Aluminum Gantry Crane for Delivery to The Philippines Packaging and Delivery

Packaging Method

The two gantry cranes were carefully packaged to ensure safe transport.

- Knockdown Packaging: The cranes were disassembled into compact sections.

- Wooden Case or Pallet: The components were securely placed in a sturdy wooden case or pallet, depending on the specific size and shape of each unit, to prevent damage during transit.

Shipping Mode

- Sea Freight: Given the destination in the Philippines, the shipment was sent via sea freight. This was the most cost-effective and reliable option for delivering large but lightweight cargo.

Delivery Timeline

- Production Lead Time: 15 working days to manufacture the cranes.

- Shipping Time: After dispatch, the estimated shipping time was about 20-30 days for sea freight, depending on the specific port and logistics schedules.

- Total Timeline: From order confirmation to final delivery, the total time was approximately 45 days.

Export Documents Prepared

To ensure smooth customs clearance, the following documents were prepared:

- Packing List: Detailing all components and their quantities.

- Invoice: For the sale transaction.

- Certificate of Origin: Verifying the cranes were manufactured in China.

Client Feedback & Outcome

Ease of On-Site Installation

The client reported that the assembly process was quick and straightforward. Since the cranes were delivered in a knockdown form, the assembly took just a few hours with minimal tools and no need for special expertise. The clear instructions included made it easy for their team to put everything together.

Performance Satisfaction

- The client was very satisfied with the crane's performance. They found it stable, reliable, and ideal for their lifting needs in the workshop.

- The aluminum frame’s corrosion resistance was appreciated, especially in their humid environment.

- The cranes performed as expected during regular lifting tasks, and the client highlighted the easy mobility of the units for repositioning when necessary.

Suggestions or Future Inquiry Potential

The client didn’t have any major suggestions for improvement. However, they expressed interest in future crane solutions should their business grow and require additional lifting capacity or specialized designs.

Long-Term Cooperation Prospects

- Given the success of this project, there is a strong possibility for long-term cooperation. The client may need more gantry cranes in the future as their workshop expands.

- Additionally, they are considering our customized solutions for other lifting tasks, which opens the door for ongoing business relationship opportunities.

Why Choose Yuantai Aluminum Gantry Cranes

When it comes to selecting the right gantry crane, here’s why Yuantai is the ideal choice for your business:

- Lightweight and Durable Design :Our aluminum gantry cranes are designed to be lightweight yet highly durable. The use of high-strength aluminum alloy ensures that the crane can handle regular lifting tasks while being easy to move and set up. This makes it a perfect solution for small workshops and tight spaces. The material is also corrosion-resistant, ensuring a long-lasting performance even in humid or challenging environments.

- Customization Available :At Yuantai, we understand that every client has unique needs. That’s why we offer customized solutions. Whether it’s adjusting the span, height, or incorporating additional features, we work closely with our clients to ensure the crane meets their exact specifications. This flexibility ensures that our cranes will be a perfect fit for any application.

- Fast Response and Overseas Delivery Support :We pride ourselves on our quick response times. From the moment you inquire, our team is ready to provide expert advice and detailed quotes. For international clients, we offer efficient overseas delivery support to ensure timely shipping and smooth customs clearance. Our experienced logistics team handles all aspects of the delivery process to ensure you get your crane on time and without hassle.

- Certified Manufacturing and Quality Inspection :Yuantai’s cranes are built to the highest standards. We follow strict certified manufacturing processes and conduct thorough quality inspections. Each crane undergoes a detailed check for performance and safety, following international standards such as GB/T 14406. This commitment to quality ensures that every crane leaving our factory is reliable and safe for use in your operations.

Conclusion

Summary of the Project’s Success

The project was a success, delivering two 1-ton aluminum gantry cranes to the client in the Philippines. The cranes met all specifications, including a fixed height, lightweight frame, and manual hoist compatibility. Production and delivery were on time, and the assembly process was quick and easy.

The client was very satisfied with the crane’s performance. They appreciated the lightweight design, corrosion resistance, and stability. The cranes met their lifting needs and were easy to move and set up in their workshop.

If you're in Southeast Asia or the maintenance industry, Yuantai offers customized and cost-effective aluminum gantry cranes. Our cranes are built to last and easy to use, ideal for small-scale operations or workshops. Contact us today for a quote and find the right lifting solution for your business.