Choosing the Right Explosion-Proof Hoist for Hazardous Gas Zones

Learn key factors,ie. zone classification, lifting capacity, certification & control option to select a safe explosion-proof hoist. Get your exproof hoist!

Hazardous Gas Zones

Before choosing an explosion-proof hoist, it’s important to understand the hazardous gas zones where the hoist will be used. Different zones have different levels of risk. Knowing these zones helps you pick the right equipment and keep your workplace safe.

What Are Hazardous Gas Zones?

Hazardous gas zones are areas where flammable gases or vapors might be present. These zones are classified based on how often and how long the gas is present.

- Zone 0: This is the highest risk area. Flammable gas or vapor is present continuously or for long periods.

- Zone 1: Flammable gas or vapor is likely to occur during normal operations but not all the time.

- Zone 2: Flammable gas or vapor is not likely to occur in normal operations, but if it does, it will only be for a short time.

Why Matching Hoist Rating to Zone Matters

Explosion-proof hoists are designed and certified to work safely in specific zones. If you use a hoist that doesn’t match the zone rating, it can be dangerous. The hoist might cause sparks or heat that could ignite the gas.

Here’s why the right rating is crucial:

- Safety: Prevents accidents caused by ignition in hazardous areas.

- Compliance: Meets legal and industry standards for hazardous environments.

- Reliability: Ensures the hoist works well without unexpected shutdowns or damage.

Always check the zone classification of your work area and choose a hoist certified for that zone. This step protects people, equipment, and your facility.

Explosion-Proof Certification and Standards

When choosing an explosion-proof hoist, certifications and standards are your first guide to safety and reliability. These certifications show that the equipment has passed strict tests for use in hazardous gas environments.

- ATEX: A European certification ensuring the hoist is safe for explosive atmospheres.

- IECEx: An international certification that confirms global compliance with explosion-proof standards.

- UL: A North American safety certification, often required for equipment used in the USA and Canada.

These certifications make sure the hoist is built to prevent sparks, heat, or electrical faults that might ignite flammable gases.

Along with certifications, pay attention to gas group ratings and temperature classes.

- Gas groups like IIC or IIB classify the type of gases or vapors the hoist can safely handle. For example, IIC covers highly explosive gases such as hydrogen, while IIB covers less volatile gases like ethylene.

- Temperature classes (e.g., T4, T3) define the maximum surface temperature the equipment can reach. This is important because if the surface temperature exceeds the ignition temperature of the gas, it could cause an explosion. T4 means the surface temperature won’t exceed 135°C, safe for many common gases.

Always pick a hoist with certifications and ratings that match your work environment’s specific hazards.

Determining the Required Lifting Capacity

Choosing the right lifting capacity is crucial for safe and efficient operation. Here’s how to get it right:

- Assess Load Weight: Know the exact weight of the heaviest load you will lift regularly. Don’t guess — always use precise measurements or data.

- Maximum Lifting Height: Consider how high you need to lift your loads. The hoist should support the required height without strain.

- Future Needs: Think about potential future uses. Will you need to lift heavier loads later? Plan ahead to avoid buying a hoist that quickly becomes inadequate.

- Safety Margins: Always include a safety margin, typically 10-20% over your heaviest load. This protects the hoist from overload and extends its service life.

Taking these steps ensures you get a hoist that fits your current and future demands without compromising safety.

Selecting the Appropriate Hoist Type

Choosing the right hoist type makes a big difference in how well it fits your work needs. Here’s what to consider:

Electric Chain Hoist vs. Wire Rope Hoist:

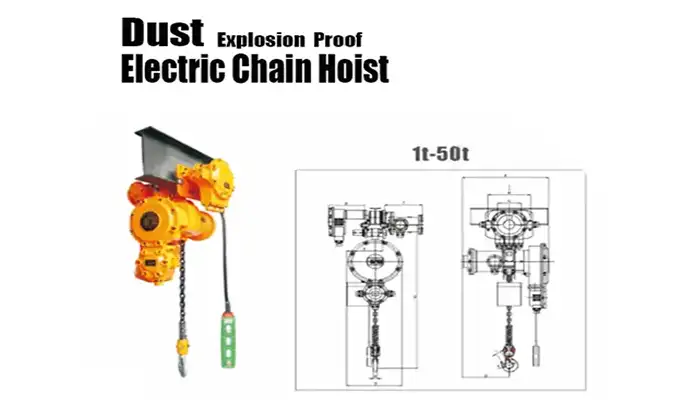

- Electric chain hoists are compact, easier to maintain, and great for medium loads. They’re perfect for tight spaces and frequent lifting.

- Wire rope hoists handle heavier loads and longer lifts. They’re better for big industrial tasks but need more space and maintenance.

Mounting Options:

- Hook Mounted: Simple to install and move around. Ideal for mobile use or quick setups.

- Manual Trolley lets you push the hoist along the beam by hand — good if power isn’t available or for precise positioning.

- Electric Trolley provides powered, smooth movement along the beam. Great for heavier loads and repetitive tasks.

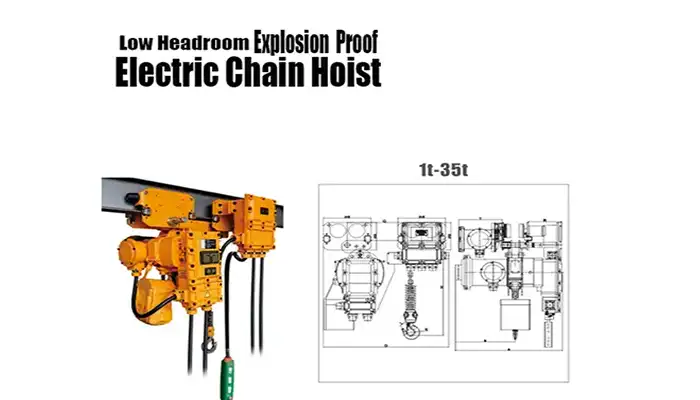

- Low Headroom: Designed to fit where overhead space is limited, maximizing lifting height without needing extra clearance.

Control System Options

How you control your hoist affects safety and ease of use. Here are the common choices:

- Wired Pendant Controls:

Simple and reliable. These are hardwired to the hoist and easy to operate. Great for most industrial settings where flexibility isn’t the top priority. - Wireless Remote Controls:

Offers freedom of movement. You can control the hoist from a distance, which improves safety and convenience, especially in larger or hazardous areas. - Variable Frequency Drives (VFD):

Optional feature that allows smooth start, stop, and speed control. This reduces wear on the hoist and load, improving safety and extending equipment life.

Picking the right hoist type and control system ensures your lifting tasks are safe, efficient, and well-suited to your specific environment.

Material and Component Quality

When it comes to explosion-proof hoists, quality is everything. The right materials and components keep your equipment safe and reliable in hazardous gas zones.

- Explosion-Proof Motor and Control Boxes:

These parts are built with thick cast iron or stainless steel housings. They prevent sparks or heat from escaping, which could ignite flammable gases. Certified to meet strict explosion-proof standards, these motors and boxes protect both the hoist and your work environment. - Corrosion-Resistant Materials:

Hoists often work in harsh, sometimes moist environments. That’s why stainless steel hooks and copper-plated chains are essential. Stainless steel resists rust and damage, while copper plating on chains helps prevent sparks — a must in explosive atmospheres. - Safety Features:

Safety isn’t optional. Overload protection systems stop the hoist from lifting beyond its capacity, avoiding dangerous strain. Mechanical and electrical limit switches prevent the hook from over-traveling up or down, protecting both people and equipment.

Installation and Maintenance Considerations

Installing and maintaining explosion-proof hoists takes special care to ensure ongoing safety and performance.

- Compliance with Hazardous Area Installation Guidelines:

Installation must follow local and international codes for hazardous zones. This includes correct grounding, proper cable sealing, and ensuring all components are explosion-proof rated for the specific gas group and zone. - Routine Maintenance:

Regular inspections are vital. Check for wear on chains, hooks, and electrical parts. Clean and lubricate components as recommended. Replace any damaged parts immediately to prevent failures. - Operator Training:

Operators must understand how to safely use explosion-proof hoists. Training covers correct operation, emergency procedures, and recognizing signs of wear or malfunction. Well-trained operators reduce risks and help keep the workplace safe.

Investing in quality materials, careful installation, and ongoing maintenance ensures your explosion-proof hoist stays safe and dependable for years.

Cost vs. Value Analysis

When choosing an explosion-proof hoist, it’s important to look beyond the initial price. Understanding the long-term value can help you make a smart investment.

- Initial Investment vs. Long-Term Costs

Explosion-proof hoists may have a higher upfront cost compared to regular hoists. However, their durable construction and design for hazardous environments reduce maintenance needs and downtime. This means you save money over time through fewer repairs and reliable operation. - Certified Equipment Matters

Certifications like ATEX, IECEx, and UL prove that the hoist meets strict safety standards. Using certified equipment lowers the risk of accidents and helps you comply with regulations. This protects your workers, assets, and company reputation.

Consulting Experts and Suppliers

Choosing the right explosion-proof hoist isn’t always straightforward. Getting advice from specialists can ensure you pick the best fit for your unique needs.

- Get Technical Advice for Custom Solutions

Hazardous areas differ in gas types, zone classifications, and lifting requirements. Experts can recommend the ideal hoist model, control method, and mounting option. Tailored solutions improve safety and efficiency at your site. - After-Sales Support & Warranty

Reliable suppliers offer more than just products—they provide installation assistance, operator training, and ongoing maintenance services. Good after-sales support keeps your hoist working safely and smoothly. Plus, warranties protect your investment against defects or issues down the road.