Cleanroom-Compatible Explosion-Proof Hoists: Safety & Cleanliness

Learn key features, benefits & selection tips for safe, clean, explosion-proof hoists in sensitive industrial environments. Get cleanroom chain hoist!

Cleanroom-Compatible Explosion-Proof Hoists: What You Need to Know

Cleanroom-Compatible Explosion-Proof Hoists are special lifting devices designed for very specific, tough environments. They combine two important features: safety in explosive areas and cleanliness for sensitive spaces.

Hoists, in general, are essential machines used to lift and move heavy loads. They make work easier and safer in factories, warehouses, and many industries.

Explosion-proof hoists are built to work safely in places where flammable gases, dust, or vapors exist. These hoists prevent sparks or heat that could cause dangerous explosions.

On the other hand, cleanroom-compatible hoists are designed for environments where even tiny dust or particles can ruin products or processes. These hoists are made to avoid contamination and are easy to clean.

Why combine both? Some industries need to handle hazardous materials in ultra-clean spaces, like pharmaceutical plants or semiconductor fabs. That’s where cleanroom-compatible explosion-proof hoists come in.

This guide will help you understand what these hoists are, why they’re important, and what you should consider if you need one.

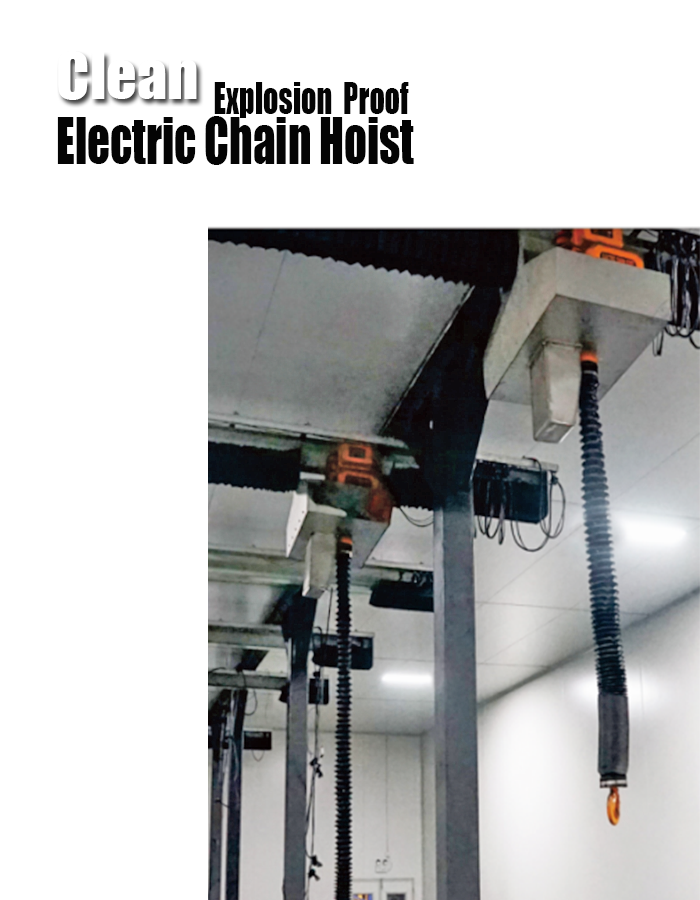

clean room explosion proof electric chain hoist for sale

Explosion-Proof Hoists

What Does “Explosion-Proof” Mean in Hoists?

Explosion-proof means the hoist is designed to prevent any sparks, flames, or heat that could ignite flammable gases, vapors, or dust nearby.

In normal hoists, electrical parts or mechanical friction can create sparks or high temperatures. These are dangerous in environments where explosive atmospheres may exist.

An explosion-proof hoist uses special construction methods and materials to ensure safety, such as:

- Sealed electrical enclosures

- Non-sparking components

- Controls that limit heat generation

The goal is to make sure the hoist can operate safely without starting an explosion, even in the worst conditions.

Where Are Explosion-Proof Hoists Needed?

Explosion-proof hoists are essential in industries with high risk of fire or explosions. Some common environments include:

- Chemical plants: where flammable liquids and gases are handled or processed

- Oil and gas refineries: full of combustible vapors and gases

- Paint shops and coating plants: airborne solvents and vapors present fire hazards

- Pharmaceutical manufacturing: certain areas use flammable solvents

- Grain handling facilities: fine dust particles can cause dust explosions

- Mining operations: explosive gases or coal dust may be present

In these places, using regular hoists is unsafe. Explosion-proof hoists help protect workers, equipment, and buildings from catastrophic accidents.

Key Standards and Certifications

To be called explosion-proof, hoists must meet strict industry standards. These certifications ensure the hoist has been tested and approved for hazardous environments:

- ATEX (EU directive): Ensures equipment meets safety requirements for explosive atmospheres in Europe.

- IECEx (International): International certification for explosion protection standards based on IEC standards.

- NEC/CEC (USA/Canada): National Electrical Code and Canadian Electrical Code set guidelines for electrical equipment in hazardous locations.

- FM (Factory Mutual) and UL (Underwriters Laboratories): Certification bodies that test and approve explosion-proof equipment for North America.

When choosing a hoist, always check for these certifications to confirm it meets local regulations and safety requirements.

Cleanroom Environments: Characteristics and Requirements

What is a Cleanroom?

A cleanroom is a controlled space designed to keep the air free from dust, particles, and other contaminants. It’s used when even tiny amounts of dirt or germs can spoil products or research.

Cleanrooms are classified by the number of particles allowed per cubic meter or cubic foot of air. The most common standard is the ISO classification, which ranges from:

- ISO 1 (almost no particles)

- Up to ISO 9 (lowest cleanliness level, almost like normal room air)

For example, an ISO 5 cleanroom allows no more than 3,520 particles sized 0.5 microns or larger per cubic meter of air. The lower the number, the cleaner the room.

Key Cleanroom Requirements Affecting Hoist Design

Hoists used in cleanrooms must meet special requirements to avoid contaminating the environment or failing due to harsh conditions:

Low Particle Generation

Hoists must be built to release as few particles as possible. This means:

- Using smooth surfaces that don’t shed dust

- Avoiding materials that degrade or flake over time

- Sealing moving parts to prevent grease or dirt from escaping

- Using special lubricants that don’t emit harmful vapors or particles

Corrosion Resistance

Cleanrooms often use strong cleaning chemicals and disinfectants. Hoists must resist corrosion caused by these agents. This usually means:

- Using stainless steel or coated metals

- Avoiding materials that rust or degrade quickly

- Designing parts that tolerate frequent washing or wiping

Contamination Control

The hoist design must prevent contamination not just from particles, but also from bacteria and other microbes. This involves:

- Minimizing crevices or gaps where dirt can accumulate

- Ensuring easy cleaning and sterilization

- Using non-porous, smooth materials that don’t absorb contaminants

Industries Using Cleanroom-Compatible Hoists

Many industries need hoists that can work safely and cleanly in sensitive environments. Some common examples are:

- Pharmaceutical industry: For lifting heavy equipment or materials inside sterile production areas.

- Semiconductor manufacturing: Where microscopic particles can ruin microchips and electronic components.

- Biotechnology labs: Where biological samples require contamination-free handling.

In all these industries, cleanroom-compatible hoists help maintain product quality and safety while supporting heavy lifting needs.

Why Combine Explosion-Proof and Cleanroom Features?

When Do Hazardous and Cleanroom Needs Overlap?

Some workplaces face two tough demands at once: they handle flammable or explosive materials, and they also need to keep the environment ultra-clean. This means the lifting equipment, like hoists, must be both explosion-proof and cleanroom-compatible.

For example, many chemical or pharmaceutical plants produce or use volatile solvents that can ignite easily. At the same time, these plants often operate cleanrooms to protect sensitive products from contamination.

In these cases, a standard explosion-proof hoist isn’t enough. It might keep sparks away but could release particles or dirt that spoil the cleanroom. Likewise, a regular cleanroom hoist may keep the air clean but isn’t safe for explosive atmospheres.

Typical Situations Where Both Features Matter

Here are some common places or processes where you need hoists with both explosion-proof and cleanroom features:

- Pharmaceutical manufacturing: Handling flammable solvents inside sterile rooms.

- Chemical plants: Mixing or packaging volatile chemicals in contamination-controlled zones.

- Semiconductor fabs: Areas using explosive gases in highly controlled cleanrooms.

- Biotech labs: Working with flammable substances while keeping sterile conditions.

- Paint and coating lines: Using flammable materials in clean spray booths.

Design and Maintenance Challenges

Making hoists that meet both explosion-proof and cleanroom standards is not easy. Some key challenges include:

- Material choice: Must resist corrosion, avoid particle shedding, and handle hazardous atmospheres. Stainless steel or special coatings are common but can be expensive.

- Sealing and protection: Electrical and mechanical parts need tight sealing to prevent sparks and stop particles from escaping. This can make maintenance more complex.

- Lubricants and fluids: Only cleanroom-safe and explosion-proof lubricants can be used, limiting options.

- Cleaning: Frequent cleaning is needed without damaging explosion-proof features. Designing for easy disassembly and reassembly is important.

- Cost: Combining both features raises manufacturing and maintenance costs. However, it’s critical for safety and product quality.

Key Features of Cleanroom-Compatible Explosion-Proof Hoists

Materials and Finishes Used

The materials chosen for these hoists play a huge role in both cleanliness and safety. Because cleanrooms need to avoid any particles or contamination, materials must be smooth, durable, and corrosion-resistant.

- Stainless steel is the most common choice. It doesn’t rust, and its smooth surface won’t easily release dust or flakes into the cleanroom air.

- Some hoists use aluminum alloys with special coatings for lighter weight but still require corrosion resistance.

- Epoxy coatings or powder coatings are often applied to parts to add an extra layer of protection. These coatings help prevent corrosion and reduce friction, which limits wear and particle generation.

- All finishes must be resistant to harsh cleaning agents since cleanroom environments require frequent and rigorous cleaning.

Sealing and Enclosure Design

Sealing is vital because dust, particles, or even moisture can damage hoist components and contaminate the cleanroom. At the same time, the design must prevent sparks or heat from escaping the hoist, which could trigger explosions in hazardous atmospheres.

- High-quality gaskets and seals are installed on all joints, doors, and moving parts to stop particles from escaping or entering.

- Electrical components are placed inside fully sealed explosion-proof enclosures that meet rigorous standards such as ATEX or IECEx. These enclosures prevent the entry of flammable gases and dust while containing any internal sparks.

- The hoist structure minimizes gaps, crevices, or pockets where dirt or contaminants can accumulate, making cleaning easier and more effective.

Lubricants and Fluids

Lubricants are often overlooked but are crucial in cleanroom-compatible explosion-proof hoists. The wrong lubricant can release harmful particles or vapors, risking both contamination and explosions.

- Use cleanroom-grade lubricants that have very low particle emissions and do not evaporate into harmful vapors.

- Lubricants must be non-flammable or have a very high flash point to comply with explosion-proof safety standards.

- They should withstand frequent cleaning and exposure to cleaning chemicals without breaking down or losing effectiveness.

- In some cases, dry lubricants or solid lubricants may be preferred to reduce contamination risk.

Electrical Components and Explosion-Proof Enclosures

The electrical parts of the hoist are a key concern because electrical sparks are a primary cause of explosions in hazardous areas. Therefore, these components must meet very strict safety rules.

- All motors, switches, and wiring are designed to meet explosion-proof certifications like ATEX, IECEx, or NEC.

- The electrical enclosures are sealed to be dust-tight and gas-tight to block any flammable atmospheres from entering.

- The design ensures that any internal sparks or arcs cannot escape the enclosure and ignite gases or dust outside.

- Wiring and connectors use special armored cables or conduits to prevent damage and exposure.

Noise and Vibration Control

Maintaining a stable cleanroom environment often means keeping noise and vibration to a minimum. Excess noise or vibration can disrupt sensitive processes or damage equipment.

- Hoists include vibration isolators or dampers to absorb shocks and reduce vibrations transferred to the cleanroom floor or structure.

- Motors and gearboxes are chosen for their smooth and quiet operation, often using precision engineering and balanced parts.

- Lower vibration also helps extend the hoist’s service life and reduces maintenance needs.

Ease of Cleaning and Maintenance

Cleanrooms demand frequent cleaning to maintain contamination levels. The hoist design must support this without compromising safety or performance.

- Surfaces are made smooth and non-porous so dirt, grease, or particles don’t stick or build up.

- Hoists are designed for easy access to critical components, so maintenance can be done quickly without removing entire assemblies.

- Components that require regular lubrication or inspection are located where they can be reached without breaking explosion-proof seals.

- Maintenance procedures must follow strict protocols to avoid introducing contaminants or damaging the explosion-proof features.

- Some hoists may include quick-release covers or modular parts to speed up cleaning and repairs.

Selection Criteria for Buyers

Choosing the right cleanroom-compatible explosion-proof hoist isn’t just about picking a model off the shelf. Buyers must carefully evaluate several key factors to ensure safety, reliability, and compatibility with their unique environment.

Assess Explosion Risk and Cleanroom Classification Compatibility

- Understand your hazardous environment: Identify the types of explosive materials or gases present, their concentration, and the ignition risk level. This helps determine the exact explosion-proof certification needed (e.g., ATEX Zone 1 or Zone 2).

- Know your cleanroom class: Be clear on the ISO classification or other cleanroom standards your facility must meet. The hoist must not release particles that exceed your cleanroom’s allowed contamination levels.

- Match hoist certifications: Make sure the hoist has certifications and features that align with both your explosion risk zone and cleanroom cleanliness class.

Load Capacity and Duty Cycle Requirements

- Calculate maximum lifting load: Determine the heaviest load the hoist will handle regularly. Overloading can cause premature failure or safety risks.

- Consider duty cycle: How often and how long will the hoist operate daily? Heavy-duty or continuous use demands more robust designs and materials.

- Factor in safety margins: Always add a safety margin (usually 10-20%) above your maximum load for unexpected situations or load fluctuations.

Customization Options for Specific Conditions

- Material choices: Depending on your cleaning chemicals or environmental conditions, you may need stainless steel, special coatings, or sealed components.

- Lubrication systems: Some hoists offer specialized lubricants or even dry-lubricated options for ultra-clean environments.

- Control features: Customized control panels, explosion-proof switches, or remote operation can improve safety and ease of use.

- Mounting and dimensions: Custom spans, hook heights, or trolley types may be required to fit your cleanroom layout.

Integration with Existing Infrastructure and Safety Systems

- Compatibility with crane runways and rails: Ensure the hoist fits and works smoothly with your current overhead crane infrastructure.

- Safety interlocks and alarms: The hoist should support integration with your facility’s safety systems, such as emergency stops, overload alarms, or explosion detection systems.

- Cleanroom workflow: The hoist must not disrupt airflow patterns or cleanroom pressure controls.

Compliance with Local Regulations and Industry Standards

- Regional certifications: Confirm that the hoist complies with local regulations—these can vary by country or region (e.g., OSHA in the U.S., ATEX in Europe).

- Industry standards: Some industries have specific requirements, such as FDA regulations for pharmaceuticals or SEMI standards for semiconductor manufacturing.

- Documentation and support: Reliable suppliers provide full certification documents, maintenance manuals, and training to ensure ongoing compliance and safety.

Common Misconceptions and FAQs

Can a Standard Explosion-Proof Hoist Be Used in a Cleanroom?

Many people think that any explosion-proof hoist will automatically work in a cleanroom. That’s not true. A standard explosion-proof hoist is built to prevent sparks and explosions in hazardous areas but may release dust, particles, or lubricants that contaminate a cleanroom environment. Cleanroom-compatible explosion-proof hoists have special materials, sealing, and lubrication to meet strict cleanliness standards. Using a non-cleanroom hoist in a cleanroom risks product contamination and can lead to costly shutdowns.

Cost Considerations vs. Long-Term Benefits

At first glance, cleanroom-compatible explosion-proof hoists cost more than standard hoists. This extra cost often surprises buyers. But it’s important to think long-term:

- Reduced downtime: Proper hoists reduce contamination and explosion risks, avoiding expensive production halts.

- Lower maintenance costs: These hoists use durable materials and are designed for easier cleaning and service.

- Improved safety: Preventing accidents and contamination protects employees and products, which is priceless.

- Compliance: Avoid fines or shutdowns by meeting regulations.

So, while the upfront cost is higher, the overall value is much greater.

Handling Emergency Situations with These Hoists

In emergencies—like a power failure or sudden gas leak—these hoists must operate safely. Most cleanroom-compatible explosion-proof hoists come with:

- Fail-safe brakes that hold loads in place if power drops.

- Emergency stop controls designed to work instantly without causing sparks.

- Robust control systems that can shut down safely when hazardous conditions are detected.

Training operators on emergency procedures is just as important as having the right equipment.

Compatibility with Automation and Remote Operation

Modern cleanrooms often use automation to improve safety and efficiency. Good news: many explosion-proof cleanroom hoists support:

- Remote controls that keep operators safely away from hazardous zones.

- Integration with automated crane systems and facility-wide control networks.

- Programmable operation modes for precise, repeatable lifts.

If you plan to automate, check with suppliers about compatibility and customization options early in the buying process.

Conclusion

Cleanroom-compatible explosion-proof hoists play a vital role in industries where safety and cleanliness cannot be compromised. Whether in pharmaceutical labs, semiconductor fabs, or chemical plants, these specialized hoists ensure that lifting tasks are performed safely without risking contamination or explosions. They combine two critical requirements: protecting people and equipment from hazardous environments, while maintaining the ultra-clean conditions necessary for sensitive processes.

Choosing the right hoist is not a one-size-fits-all decision. It requires a clear understanding of your facility’s explosion risks, cleanroom classifications, load demands, and maintenance capabilities. Taking time to evaluate these factors carefully will help you avoid costly mistakes, reduce downtime, and keep your operations running smoothly and safely.

If you’re unsure about the best hoist for your specific environment, don’t hesitate to reach out to experienced manufacturers or technical experts. They can provide customized solutions tailored to your exact needs, offer detailed quotations, and guide you through compliance and installation processes. With the right partner, you can secure a hoist that meets both your cleanroom and explosion-proof requirements, helping your business maintain the highest standards of safety and quality.