Dual-Purpose overhead crane with grab bucket and electromagnetic lifting for efficient bulk material and steel handling in heavy industries.

Introduction

The QP type dual-purpose overhead crane is a smart choice for heavy-duty industrial lifting. Unlike a standard overhead crane, it combines two lifting tools in one system: a grab bucket and an electromagnetic lifter. This makes it more versatile for handling different types of materials.

What Is a QP Type Dual-Purpose Overhead Crane?

This crane is designed to perform two jobs:

- Use the grab bucket to lift loose materials like coal, sand, or scrap metal.

- Switch to the electromagnetic chuck to lift steel plates, billets, or rebar.

That’s why it’s called a dual-purpose overhead crane—it does both grabbing and magnetic lifting with one machine.

Why Choose a Dual-Purpose Overhead Crane?

Many industries need to handle both bulk and solid steel materials. Instead of installing two overhead cranes, one dual-purpose crane covers both jobs.

It brings several benefits:

- Cost-effective – no need to buy and maintain two cranes.

- Space-saving – needs only one set of tracks and structure.

- Time-saving – easy to switch between grab and magnet modes.

It’s also built for high-duty use (usually A6), which means it works well under continuous and heavy operation.

Common Applications

The QP dual-purpose overhead crane is widely used in:

- Steel mills – for loading and unloading steel scrap, billets, and slabs.

- Scrap yards – to sort and move large amounts of metal waste.

- Ports and terminals – where both loose goods and metal items are handled.

- Foundries and warehouses – for feeding materials into production lines or organizing stock.

In short, if your facility handles both loose and solid materials, this type of overhead crane gives you the flexibility you need. It’s tough, efficient, and built to handle demanding work environments.

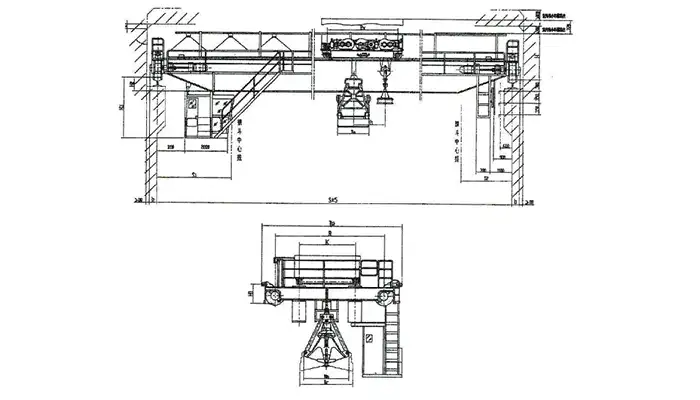

![drawing of dual purpose overhead crane for sale]()

Key Features of QP Type Dual-Purpose Overhead Crane

The QP overhead crane is specially designed for dual lifting needs—ideal for facilities handling both bulk and magnetic materials. Below are its main features:

Dual Lifting Modes (Grab + Magnet)

This is the most important feature.

The QP crane can lift:

- Loose materials (scrap, ore, coal, etc.) using a grab bucket.

- Magnetic items (steel plates, bars, billets, etc.) using an electromagnetic chuck.

Switching between grab and magnet is fast and simple. It saves space and reduces equipment costs, making it perfect for multi-use applications.

Standard and Custom Lifting Capacities

Available models include:

- 5/5t, 10/10t, and 16/16t — each figure means equal capacity for both grab and magnet.

- Customized capacities available to meet site-specific requirements or heavy load handling.

High Working Class (A6 Duty)

This dual-purpose overhead crane is rated A6, which means:

- Designed for frequent use and heavy-duty operations.

- Suitable for long working hours and higher production demands.

- Commonly used in steel mills, foundries, and recycling plants where crane use is intense.

Integrated, Complete System

Every QP crane includes:

- Bridge frame – spans the workshop; built for strength and stability.

- Trolley with hoisting mechanism – runs along the bridge, carries the grab or magnet.

- Grab bucket + Electromagnetic lifter – quickly changeable depending on material.

- Electrical & control systems – includes motors, wiring, protection, and either cab or remote control options.

All systems are integrated for safe, smooth, and reliable operation.If your job requires handling both scrap and steel, the QP dual-purpose overhead crane brings solid performance, saves space, and cuts down your equipment list.

Applications of QP Type Dual-Purpose Overhead Crane

The QP type dual-purpose overhead crane is specifically designed for handling a wide range of materials using either a grab bucket or an electromagnetic lifting system. It suits operations where both magnetic and non-magnetic materials need to be moved frequently and efficiently.

Materials Handled

This crane handles a variety of material types, including:

- Steel scrap – irregular, heavy, and often sharp-edged materials.

- Bulk metal materials – such as pig iron, broken castings, or foundry returns.

- Granular materials – like ore, metal chips, coal, or similar particles that require a grab bucket.

- Unpacking-free steel products – such as bundled steel bars, billets, steel plates, and coils, which can be lifted directly by the magnet without unpacking.

This flexibility makes the QP crane valuable in material handling processes that require both lifting precision and high efficiency.

Indoor and Outdoor Use

The QP dual-purpose overhead crane is suitable for both indoor workshops and outdoor yards. Its structure and components can be adjusted to suit different environments. Optional protective measures include:

- Rain and weather protection for outdoor models

- Dust-resistant design for dirty or open environments

- Heat-resistant parts for high-temperature areas like near furnaces

This allows for consistent performance regardless of the installation location.

Common Industrial Applications

- Steel Plants: Used to transport steel billets, coils, slabs, scrap, and metal returns. Helps automate internal transfer between different production lines or storage areas.

- Foundries: Efficient for loading furnaces with scrap metal or removing casting returns. Its dual function reduces the need for multiple cranes in the melting and casting areas.

- Scrap Yards: Handles various sizes and types of metal scrap. The magnet quickly picks up ferrous material, while the grab can scoop up non-magnetic or mixed scrap.

- Cargo Terminals and Warehouses: Used to load or unload metal cargo from trucks, railcars, or ships. Can move unpackaged or bundled metal goods with minimal manual handling.

In summary, if you’re handling a mix of scrap, bulk materials, and steel products in one place, the QP type dual-purpose overhead crane is an efficient, space-saving, and cost-effective solution. It's built to take on heavy-duty tasks in both demanding indoor and outdoor environments.

Technical Specifications Overview of QP Type Dual-Purpose Overhead Crane

| Capacity |

t |

5/5 Ton |

10/10Ton |

16 / 16Ton |

| Working Duty |

A6 |

| Span |

m |

10.5 |

13.5 |

16.5 |

19.5 |

22.5 |

25.5 |

28.5 |

31.5 |

13.5 |

16.5 |

19.5 |

22.5 |

25.5 |

28.5 |

31.5 |

19.5 |

22.5 |

25.5 |

28.5 |

31.5 |

| Max Lifting Height |

Grab Bucket |

m |

20 |

18 |

22 |

| Electromagnet |

16 |

22 |

22 |

| Speed |

Lifting Height |

Grab Bucket |

m/min |

40.1 |

40 |

41.8 |

| Electromagnet |

15.6 |

10.4 |

13 |

| Trolley Travelling Speed |

44.6 |

45.6 |

43.2 |

| Crane Travelling Speed |

93.7 |

86.4 |

76 |

89 |

75.3 |

| Motor |

Lifting Height |

Grab Bucket |

kw |

YZR225M-8/22 |

YZR208S-10/37 |

YZR315M-10/ 75 |

| Electromagnet |

YZR180L-6/15 |

YZR200L-6/22 |

YZR250M-6 / 37 |

| Trolley Travelling Speed |

YZR132M2-6 /3.7 |

YZR160M-6/5.5 |

YZR160M2-6/ 7.5 |

| Crane Travelling Speed |

YZR160M-6/5.5×2 |

YZR160M2-6/7.5×2 |

YZR160M2-6/7.5×2 |

YZR160L-6/11×2 |

YZR160L-6/ 11×2 |

| Max. Dimentions |

BQ |

6355 |

6485 |

7090 |

6385 |

6485 |

7145 |

6870 |

7000 |

| B |

4000 |

4100 |

5000 |

4000 |

4100 |

5000 |

4800 |

5000 |

| Bx |

3550 |

4420 |

5250 |

| b |

230 |

250 |

300 |

| k |

2000 |

2500 |

| H |

1893 |

1943 |

2095 |

2185 |

2418 |

2548 |

| H3 |

2548 |

2608 |

2708 |

2858 |

3008 |

3108 |

3258 |

3408 |

2610 |

2760 |

2770 |

2920 |

3070 |

3220 |

3320 |

2924 |

2944 |

3094 |

3194 |

3290 |

| H1 |

735 |

785 |

890 |

880 |

1010 |

| H4 |

840(MW1-6)1165(MW1-16) |

1165(MW1-16) |

1165(MW1-16)1642(MW1-45) |

| S1 |

1520 |

1700(1800) |

2175(2275) |

| S2 |

1500 |

1500(1600) |

1575(1675) |

| H2 |

128 |

228 |

328 |

478 |

628 |

728 |

878 |

1028 |

230 |

380 |

380 |

530 |

680 |

830 |

930 |

544 |

564 |

714 |

814 |

914 |

| Weight |

Hoist Trolley |

t |

7.6(8.4) |

12.4(13.3) |

20(21.2) |

| Gross Weight |

Indoor |

23.7 |

25.3 |

27.3 |

30.1 |

32.9 |

37.7 |

41.4 |

44.7 |

28.4 |

31.1 |

35 |

38.4 |

43 |

46.8 |

50.4 |

56.7 |

60.8 |

66.5 |

68.3 |

73 |

| Indoor |

24.7 |

26.3 |

28.3 |

31.1 |

33.9 |

38.7 |

42.4 |

45.7 |

29.3 |

32.5 |

35.8 |

39.3 |

43.9 |

47.8 |

51.2 |

58.1 |

61.7 |

66.8 |

69.7 |

74.2 |

| Max. Wheel Presure |

Outdoor |

KN |

106 |

113 |

120 |

131 |

134 |

151 |

161 |

171 |

159 |

173 |

186 |

196 |

209 |

219 |

229 |

241 |

253 |

264 |

275 |

283 |

| Grab Bucket |

Model |

U |

113 |

109 |

110 |

105 |

106 |

101 |

102 |

127 |

123 |

124 |

119 |

120 |

115 |

116 |

141 |

137 |

138 |

133 |

134 |

129 |

130 |

| Types |

Light |

Medium |

Heavy |

Super Heavy |

Light |

Medium |

Heavy |

Super Heavy |

Light |

Medium |

Heavy |

Super Heavy |

| Volume |

M3 |

2.5 |

1.5 |

1 |

0.75 |

5 |

3 |

2 |

1.5 |

8 |

4.8 |

3.2 |

2.5 |

| Capacity |

t/m3 |

≤1 |

>1-1.7 |

>1.7-2.5 |

>2.5-3.3 |

≤1 |

>1-1.7 |

>1.7-2.5 |

>2.5-3.3 |

≤1 |

> 1-1.7 |

>1.7-2.5 |

>2.5-3.3 |

| Self-weight |

kg |

2633 |

2549 |

2615 |

2506 |

2568 |

2479 2546 |

4800 |

4803 |

4866 |

4856 |

4913 |

4730 |

4793 |

7841 |

7993 |

8143 |

8008 |

8159 |

8155 |

8305 |

| Main Dimensions (mm) |

Ba |

1634 |

1444 |

1238 |

1160 |

2060 |

1764 |

1528 |

1416 |

2350 |

2078 |

1792 |

1628 |

| Bb |

2425 |

2175 |

2025 |

1875 |

2970 |

2670 |

2470 |

2230 |

3515 |

3515 |

2915 |

2665 |

| Bc |

3120 |

2740 |

2900 |

2530 |

2690 |

2340 |

2500 |

3900 |

3430 |

3590 |

3220 |

3380 |

2920 |

3080 |

4380 |

4050 |

4250 |

3750 |

3950 |

3430 |

3630 |

| Hp |

3135 |

2935 |

3015 |

2835 |

2915 |

2735 |

2815 |

3990 |

3747 |

3827 |

3640 |

3720 |

3490 |

3570 |

4775 |

4605 |

4705 |

4455 |

4455 |

4285 |

4385 |

| Hb |

3615 |

3385 |

3605 |

3255 |

3475 |

3125 |

3345 |

4560 |

4297 |

4517 |

4125 |

4345 |

3910 |

4130 |

5530 |

5243 |

5483 |

4979 |

5219 |

4811 |

5051 |

| Electromagnet |

Model |

MW1-6 |

MW1-16 |

MW1-16 |

MW1-16 |

MW1-45 |

| Lifting Capacity |

kg |

4540 |

3330 |

8330 |

14330 |

10450 |

| Self-weight |

460 |

1670 |

1670 |

1670 |

5550 |

| Diameter |

mm |

776 |

1180 |

1180 |

1180 |

1650 |

| Recommended Rails |

43kg /m |

QU70 |

| Power Supply |

3 Phase50HZ 380V |

The QP type dual-purpose overhead crane combines a grab bucket and an electromagnetic lifting system. Its specs can be customized to meet your site and operational needs.

Lifting Capacities

- Standard configurations: 5/5t, 10/10t, 16/16t (grab/magnet).

- Custom lifting capacities are available if you need something outside the standard range.

Span Range

- Span sizes: from 10.5 meters to 31.5 meters.

- Multiple options help match different workshop widths and layouts.

Lifting Heights

- Grab bucket lifting height: up to 22 meters.

- Electromagnet lifting height: also up to 22 meters.

- You can adjust height during design based on installation space.

Lifting & Traveling Speeds

- Grab and magnet hoisting have separate speed controls for better handling.

- Trolley and crane traveling speeds are designed for high-efficiency material movement.

Motors & Power

- Operates on three-phase AC 380V, 50Hz (standard industrial voltage in many regions).

- Equipped with YZR motors known for strong torque and reliable duty cycles.

![grab bucket overhead crane]()

Grab Bucket Specifications

This overhead crane uses different grab buckets based on material type and density.

Types of Grab Buckets

- Options include light, medium, heavy, and super-heavy types.

- Designed to suit different materials and workloads.

Bucket Volume

- Capacity ranges from 0.75 cubic meters to 8 cubic meters.

- Ideal for both light bulk and dense heavy materials.

Material Density Range

- Handles materials from less than 1 t/m³ (like coal) to over 3.3 t/m³ (dense scrap).

Other Notes

- Self-weight and dimensions vary depending on the bucket type.

- You can select or customize the grab based on your handling material.

![Electromagnetic overhead crane]()

Electromagnetic System

The crane includes a reliable electromagnetic lifting system for ferrous materials.

Magnet Types

- Common models: MW1-6, MW1-16, MW1-45 series.

- Each type is matched with specific lifting loads and disk sizes.

Suction Capacity

- Ranges from 3.3 tons up to 14.3 tons depending on disk type and material.

Magnet Size and Weight

- Available in different diameters and weights.

- Larger magnets are used for lifting steel plates or big billets.

Materials Handled

- Suited for lifting steel plates, rebars, coils, billets, and bundled materials.

- Also effective for stacking and transferring in bulk storage areas.

This combination of technical options makes the QP type dual-purpose overhead crane suitable for complex material handling environments like steel plants, scrap yards, and cargo terminals.

Working Environment

The QP type dual-purpose overhead crane is built for demanding industrial use, but it has clear environmental limitations to ensure safe and long-lasting performance.

Not Suitable for Hazardous Zones

- This crane must not be used in explosive or strongly corrosive environments.

- Avoid installing in places with flammable gases, chemical fumes, or acid vapors.

- If you need similar functionality for hazardous areas, consider explosion-proof crane models instead.

Temperature Conditions

- Standard design supports ambient temperatures from -20°C to +40°C.

- If your location experiences extreme cold or high heat outside this range, special configurations or protective enclosures may be needed.

Humidity and Dust Control

- Designed to work in standard industrial humidity levels.

- High humidity or sudden condensation may affect electrical parts—especially the magnet and control panels.

- In dusty environments, regular cleaning and sealing of electrical enclosures are recommended to avoid failures.

Indoor and Outdoor Use

- Can be installed both inside workshops or outdoors under a gantry shed.

- For outdoor setups, weatherproofing is recommended for the magnet, control systems, and motors.

Operation Modes

The crane supports flexible control methods to meet different worksite and operator preferences.

Ground Control

- Can be operated from the ground using a wireless remote control.

- This is ideal for jobs with frequent movement or when visibility from the ground is better than from a cabin.

- Helps reduce the need for permanent cabin staff.

Cabin Operation

- Comes with an operator cabin, either open or closed type.

- Closed cabins offer better protection in dusty, windy, or hot conditions.

- Cabin includes full visibility, ergonomic seating, and joystick control.

Flexible Cabin Installation

- The cabin can be installed on either the left or right side of the bridge.

- Entry options include side access or end access, depending on your crane layout and building structure.

- This allows better matching with the operator’s workflow and the material loading/unloading points.

Customization & Options

One of the biggest advantages of the QP type dual-purpose overhead crane is its flexibility. It’s designed to be tailored precisely to your specific needs. Here’s what you can customize:

Non-Standard Designs

- We can design and build non-standard cranes if your project requires something beyond the typical specifications.

- Whether you need unusual lifting capacities, spans, or special attachments, the manufacturer can create a solution for you.

- This is especially useful for unique workshop layouts, difficult handling tasks, or integration with existing equipment.

Grab Bucket Sizes and Types

- The crane supports a variety of grab buckets — from light to super-heavy types.

- You can choose the volume that matches your material handling: small grabs for fine granular materials or large buckets for bulk scrap.

- Grab shapes and materials can be adapted depending on the density and type of material to be handled, improving efficiency and reducing spillage.

Magnet Options

- Several electromagnet models are available to match the weight and type of steel loads you handle.

- Different magnet diameters and lifting capacities are offered, so you can pick the right magnet whether you’re handling thin steel plates, thick billets, or irregular scrap.

- Optional magnet coatings and weatherproofing can be added for harsh outdoor conditions.

Custom Spans and Heights

- Crane spans can be tailored from 10.5 meters up to over 30 meters, depending on your workspace and rail setup.

- Lifting heights can also be adjusted to meet the vertical clearance you need, whether in a low-ceiling warehouse or a tall cargo terminal.

- Customized travel speeds for the hoisting mechanism and trolley ensure your workflow is smooth and productivity stays high.

Electrical Adaptations

- The crane’s electrical system is designed for three-phase AC 380V, 50Hz power, but can be customized.

- For customers in different countries or regions, adaptations can be made to match local power standards (e.g., 400V, 60Hz) and safety regulations.

- Control systems can be upgraded with extra safety features, automation, or remote monitoring capabilities if required.

With these customization options, the QP type dual-purpose overhead crane can be perfectly adapted to fit your specific material handling needs, environment, and local conditions. This flexibility helps you get the best performance and value from your investment.

![crane installation services]()

Delivery & Installation

When you order a QP type dual-purpose overhead crane, here’s what to expect on delivery and installation:

- Lead Time: Typically, manufacturing takes about 40 to 60 days. This allows for careful customization and quality checks.

- Delivery Options: We offer nationwide delivery across the country. You can either pick up the crane yourself at the factory or Opt for door-to-door shipping right to your site, depending on your preference.

- Installation: While installation isn’t included by default, it is available as an optional service. We provide professional installation by experienced technicians.Installation cost is quoted separately based on site conditions and project complexity.

- Installation Support: For customers who want to do installation themselves, we supply detailed guidance and remote support to ensure smooth setup.

After-Sales Support

We stand by our products and make sure you’re supported even after purchase:

- Warranty: Every QP crane comes with a one-year warranty covering manufacturing defects and major components.

- Spare Parts: We maintain a good stock of key spare parts to help you with quick replacements and reduce downtime.

- Technical Support: Our team offers ongoing technical support and troubleshooting through phone, email, or on-site visits.

We’re here to help with any questions or maintenance needs.Support includes guidance on operation, repairs, and upgrades.

Selection Tips for Buyers

Choosing the right QP type dual-purpose overhead crane can make a big difference in efficiency and safety. Here are some key tips to help you decide:

How to Choose Between Different Capacities

- Match the lifting capacity to your heaviest load to avoid overloading.

- For mixed loads, consider a crane with dual capacities (e.g., 5/5t or 10/10t) to handle both grab and magnet operations efficiently.

- If unsure, opt for a slightly higher capacity for future-proofing.

Choosing the Right Grab Type and Magnet

- Grab bucket types vary by material density and volume: light, medium, heavy, or super-heavy. Select one based on what you mostly handle.

- For steel plates or billets, check the magnet suction capacity and diameter to ensure a secure grip.

- Custom grab sizes and magnet types are available—discuss your exact materials with the supplier.

Installation Site Preparation Checklist

- Confirm the span and height clearances match the crane specs.

- Check the power supply compatibility (usually three-phase 380V, 50Hz).

- Ensure the site is free of explosive or corrosive hazards.

- Plan for crane runway beams and structural support capable of handling the crane’s weight and maximum wheel loads.

- Decide on operation mode (ground remote control or cabin) and ensure space and safety for operators.

Considerations for Indoor vs. Outdoor Use

- For indoor use, ensure the crane fits within building dimensions and ventilation requirements.

- For outdoor use, confirm the crane has weather protection features and is rated for the local climate (temperature, humidity, dust).

- Outdoor cranes might need additional corrosion protection and waterproofing on electrical components.

Conclusion

The QP Type Grab and Electromagnetic Dual-Purpose Overhead Crane offers a powerful combination of versatility and efficiency. With its ability to switch seamlessly between grab bucket and electromagnetic lifting, it meets a wide range of handling needs — from steel scrap and bulk materials to unpackaged steel products.

Why Choose This Dual-Purpose Overhead Crane?

- Versatile Operation: Handles different materials without needing separate cranes.

- Customizable Capacities: Available in multiple tonnages and adjustable to your specific requirements.

- High Durability: Built for heavy-duty, frequent use with an A6 working class rating.

- Adaptable Design: Flexible spans, lifting heights, and operation modes to fit your site conditions.

- Reliable Support: Backed by professional after-sales service and warranty.

Whether you’re running a steel mill, warehouse, or port terminal, this overhead crane offers reliable performance and cost-effective material handling.

If you want to learn more, get a quote, or discuss customization, please reach out to our team. We’re here to help you find the right crane solution for your needs.