Overhead Intelligent Cranes: Transforming Material Handling with AI

AI-powered overhead cranes optimize material handling, improving efficiency, safety, and cost savings in various industries.

Introduction

Overview of the Industrial Revolution 4.0

The Industrial Revolution 4.0, also known as Industry 4.0, is all about smart technology. Automation and digitalization are at its core, and it's changing the way industries work. We're seeing robots, artificial intelligence, and the Internet of Things (IoT) becoming part of everyday operations. Factories, warehouses, and even ports are now using smart systems to increase productivity and reduce errors.

In industries like material handling, this shift is creating a more connected and automated environment. Machines can talk to each other, share data, and work more efficiently than ever before. The goal? To make processes faster, safer, and cheaper.

The Role of AI in Material Handling

Now, let’s talk about AI cranes. These are not your average overhead cranes. With AI, cranes are becoming much smarter.

- AI in Cranes: Artificial intelligence allows cranes to "learn" from their environment. It can predict things like the weight of a load, the best way to move it, or how to avoid obstacles.

- How It Works: Machine learning algorithms process data from sensors and cameras to optimize crane movement. The system improves as it gathers more data, leading to better decision-making.

- Real-time Adjustments: Unlike traditional cranes, AI cranes can adjust their behavior in real-time. For example, if there’s a sudden change in load or speed, the AI makes the necessary tweaks without human intervention.

With these abilities, AI cranes can perform more precise lifts, reduce downtime, and increase overall efficiency.

Why It Matters

So, why should industries care about AI cranes? It’s simple—AI brings huge benefits to material handling.

- Boosts Efficiency: AI cranes can speed up operations by making smarter, faster decisions. They can handle repetitive tasks without getting tired or making mistakes.

- Improved Safety: AI cranes can monitor their surroundings and avoid collisions, keeping workers and equipment safe. It’s like having a built-in safety net.

- Cost Savings: With better efficiency comes lower costs. AI can predict when a crane will need maintenance, reducing expensive breakdowns. Plus, more accurate operations mean less waste and fewer errors.

At the end of the day, AI cranes represent the future of material handling. They make operations smoother, safer, and more cost-effective. Industries that adopt this technology are setting themselves up for success in an increasingly digital world.

What are AI Cranes?

Definition of AI Cranes

AI cranes are overhead cranes that use artificial intelligence to enhance their performance and functionality. Unlike traditional cranes, which are operated manually or semi-automatically, AI cranes rely on machine learning algorithms, sensors, and data analysis to make smarter decisions. These cranes can process large amounts of real-time data and adjust their actions based on that information, all while improving their operation over time.

- Machine Learning Algorithms: At the heart of an AI crane is its ability to learn and adapt. Machine learning algorithms analyze data collected from the crane's sensors, cameras, and other systems. This allows the crane to "understand" how to lift loads efficiently and safely, adjusting to different conditions as needed.

- Automation: With automation, AI cranes can perform tasks on their own, like controlling the hoist or adjusting the movement speed. The system continuously monitors and adjusts the crane's performance to optimize material handling.

Key Features of AI Cranes

AI cranes come with several features that set them apart from traditional cranes. These features make them more efficient, flexible, and safe. Here’s how they differ:

- Self-Learning Capabilities: AI cranes can "learn" from their environment and improve over time. For example, by analyzing patterns in the material being lifted or the layout of the workspace, the crane can make better decisions for future lifts.

- Real-Time Adjustments: One of the biggest advantages of AI cranes is their ability to adjust instantly. For example, if a load shifts unexpectedly or if the crane encounters an obstacle, the AI system can immediately adjust the crane’s speed, direction, or lifting capacity without needing manual intervention.

- Smart Sensors: AI cranes are equipped with advanced sensors that gather real-time data about their surroundings. These sensors help the crane detect obstacles, measure load weights, and even track the crane's position. This makes the crane more precise and responsive, reducing the chance of errors.

AI Integration in Cranes

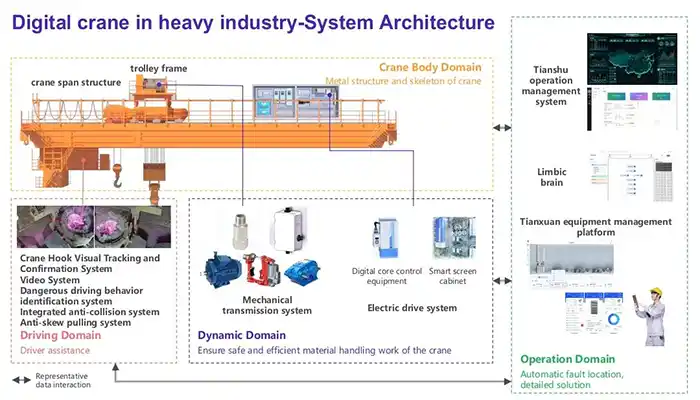

AI is integrated into various components of the crane, making the entire system smarter and more efficient:

- Hoists: AI enhances hoist systems by ensuring that lifting speeds are optimized for different loads and conditions. It can also monitor the condition of the hoist, predicting maintenance needs to prevent failures before they occur.

- Controls: AI controls are the "brain" of the crane. They process all the data collected by the sensors and use machine learning to make decisions in real time. For instance, AI can determine the most efficient path to move a load based on current conditions, like load weight and environmental factors.

- Sensors: Sensors play a crucial role in AI cranes. They track everything from load weight to the crane’s movement within its space. These sensors feed data to the AI system, which uses it to adjust the crane’s operation for maximum efficiency and safety.

AI’s integration into these components allows the crane to perform in ways that traditional cranes simply cannot. It makes the entire operation smoother, more reliable, and more adaptable to changing conditions.

The Role of AI and Machine Learning in Overhead Cranes

Machine Learning Algorithms

Machine learning algorithms play a vital role in AI cranes by enabling them to optimize material handling tasks in real-time. These algorithms analyze data from various sensors and systems, allowing the crane to make intelligent decisions on how to lift and move materials.

- Load Prediction: AI cranes use machine learning to predict the weight of loads. By analyzing previous lifting data, the crane can estimate the weight and adjust its lifting capacity accordingly. This ensures that the crane operates within safe limits, preventing overloads and reducing the risk of accidents.

- Path Optimization: The crane can also use machine learning to find the most efficient path for moving a load from one point to another. It considers factors like the layout of the workspace, load weight, and potential obstacles. By optimizing the path, the crane reduces the time spent on each lift, improving overall efficiency and productivity.

- Smart Decision Making: Machine learning allows the crane to "learn" from each lift it performs. For example, if the crane encounters a specific challenge (e.g., a tight space or an uneven load), it can adjust its behavior for future lifts, making the system more intelligent over time.

These capabilities help cranes perform tasks more efficiently, reduce human error, and ensure precise control in material handling.

Predictive Maintenance

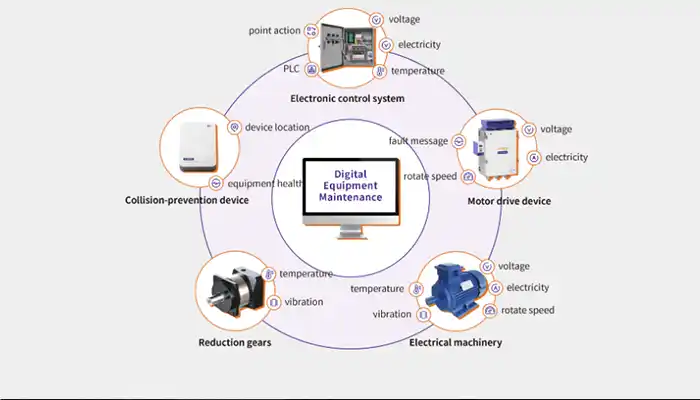

Predictive maintenance is one of the most powerful benefits of AI in overhead cranes. AI systems continuously monitor the crane's components (like motors, hoists, and gears) to predict when maintenance is needed.

- Monitoring Components: The crane’s sensors collect data on factors like vibration, temperature, and wear on mechanical parts. AI algorithms analyze this data to detect any unusual patterns that might indicate an issue, such as an impending failure in the hoist mechanism or motor.

- Forecasting Failures: By comparing current sensor data with historical performance data, AI can forecast when a component is likely to fail. For instance, if the system detects unusual vibrations in the hoist, it can predict that the part might fail soon, allowing operators to schedule maintenance before a breakdown occurs.

- Reducing Downtime and Costs: Predictive maintenance helps reduce unscheduled downtime and costly repairs by catching potential problems early. It also ensures that replacement parts are available when needed, minimizing disruptions to operations. With AI, the crane’s maintenance is planned and optimized, resulting in more uptime and reduced maintenance costs.

Automation and Self-Adaptation

AI-enabled cranes are designed to be highly adaptable, adjusting their behavior based on changing environments and tasks. This self-adaptation makes them far more efficient and versatile compared to traditional cranes.

- Environmental Adaptability: AI cranes can adjust to changes in the environment, such as shifting loads, weather conditions, or unexpected obstacles. For example, if a load becomes unbalanced, the AI system can automatically slow the crane down or change its movement pattern to ensure safe operation.

- Task Flexibility: AI cranes can adapt to a wide variety of tasks. Whether it’s moving heavy steel billets in a steel mill or lifting delicate items in a warehouse, AI cranes can adjust their lifting strategies to suit the material and environment. They learn from each task, improving their approach with every lift.

- Self-Optimization: Over time, AI cranes continuously optimize their performance. They learn the most efficient ways to move specific types of loads and adjust their behavior based on feedback from each operation. This helps the crane operate at peak efficiency without needing constant adjustments from operators.

AI cranes bring significant improvements to overhead crane systems, increasing their accuracy, efficiency, and ability to adapt to dynamic work environments. This makes them a game-changer in material handling, particularly in industries where fast, precise, and safe lifting is critical.

Key Benefits of AI in Material Handling

Increased Efficiency

One of the biggest advantages of AI cranes is the boost in efficiency they bring to material handling operations. Here's how AI helps:

- Reducing Human Error: Traditional cranes rely heavily on human operators, who can make mistakes. AI cranes, on the other hand, minimize human error by using machine learning to make decisions based on real-time data. This leads to more accurate lifts and faster handling, as the AI system doesn't tire or make mistakes under pressure.

- Faster Operations: AI cranes can optimize movements by predicting load weights, adjusting speeds, and minimizing unnecessary stops. These automatic adjustments allow for smoother and quicker lifting and transportation. For example, AI can select the optimal path to reduce the time spent on each lift and make the entire process more efficient.

- Maximized Productivity: AI systems continuously monitor and adjust crane performance, ensuring that the crane is always operating at its best. This constant optimization leads to higher throughput, allowing operations to move faster and handle more materials in less time.

Safety Enhancements

Safety is always a top concern in material handling, especially when dealing with heavy loads and complex environments. AI cranes improve safety in several key ways:

- Real-Time Monitoring: AI cranes are equipped with advanced sensors that monitor the crane’s environment continuously. These sensors detect obstacles, changes in load, and any other potential safety risks in real-time. When a danger is detected, the AI system can adjust the crane’s behavior immediately, preventing accidents before they happen.

- Adaptive Systems: AI enables cranes to adapt to changing conditions. If a load shifts unexpectedly or the crane encounters an obstacle, the AI system will automatically slow down or change the crane’s direction. This adaptability ensures that the crane operates safely, even in unpredictable environments.

- Collision Prevention: AI cranes can be programmed to recognize and avoid collisions. By using sensors and cameras, the AI system can predict the path of moving objects and adjust the crane’s movements to prevent accidents. This reduces the risk of damage to materials, equipment, and personnel.

Cost Savings

AI cranes may require an initial investment, but the long-term savings they provide make them a smart choice for many industries.

- Reduced Maintenance Costs: AI cranes predict when maintenance is needed, which prevents sudden breakdowns and expensive repairs. By detecting issues early, AI systems ensure that parts are replaced before they fail, which reduces downtime and costly emergency repairs.

- Longer Lifespan of Equipment: With AI's predictive maintenance capabilities, cranes are kept in better working condition over time. Regular maintenance based on real-time data helps extend the life of the crane and its components, saving companies money on replacement costs.

- Energy Savings: AI can also optimize the energy usage of cranes. For example, the system can adjust the crane’s power consumption based on load weight and task requirements. This prevents overuse of energy during lighter tasks, leading to overall energy savings.

Customization and Flexibility

AI cranes offer a high level of customization and flexibility, making them suitable for a wide range of material handling tasks.

- Adaptability to Different Tasks: Whether you're handling heavy materials in a steel mill or delicate items in a warehouse, AI cranes can be customized to fit the job. The AI system adjusts to the specific characteristics of the material being lifted, including its weight, shape, and fragility. This ensures that the crane handles each load in the most efficient and safe way.

- Adjusting to Different Environments: AI cranes can also adapt to different working environments. Whether it’s a busy manufacturing floor, a tight space in a warehouse, or an outdoor loading dock, the AI system constantly monitors and adjusts the crane’s movements to optimize performance in any situation.

- Scalability: As your business grows or your needs change, AI cranes can be adapted and scaled to handle more complex tasks. The ability to modify crane behavior and functionality ensures that AI cranes can continue to meet evolving operational demands.

In summary, AI cranes offer numerous benefits that help businesses improve efficiency, enhance safety, reduce costs, and remain flexible in an ever-changing industrial environment. With the ability to adapt to different materials, environments, and tasks, AI cranes are not only a smart investment but also a long-term solution for improving material handling operations.

Applications of AI Cranes in Industry

AI cranes are revolutionizing industries across the board by enhancing precision, efficiency, and safety. Here’s a closer look at how they are being used in various sectors:

Steel Mills

Steel mills are some of the most demanding environments for material handling, and AI cranes are stepping up to meet the challenge. These cranes are used for precise tasks like billet handling, furnace operations, and moving molten materials.

- Billet Handling: AI cranes can lift and transport steel billets with high precision, minimizing the risk of damage. The AI system continuously monitors the weight and condition of the billet and adjusts the crane’s movements to ensure the load is handled safely.

- Furnace Operations: In steel mills, molten steel is often moved using overhead cranes. AI systems help by predicting the best times to move molten metal, adjusting crane movements to avoid spilling or overheating, and ensuring that the crane operates at optimal speeds for safety.

- Heat and Environmental Adaptation: AI cranes are also capable of adapting to the extreme heat and harsh conditions found in steel mills. AI systems monitor environmental factors such as temperature and air quality to adjust the crane’s operations accordingly.

By using AI, steel mills can improve productivity, reduce human error, and ensure that operations are carried out safely in high-risk environments.

Automotive and Manufacturing Plants

In automotive and manufacturing plants, AI cranes play a crucial role in handling heavy components, supporting assembly lines, and ensuring smooth workflow between production stations.

- Heavy Lifting: Automotive plants require overhead cranes to move large car parts, engines, and assemblies. AI cranes can handle these heavy lifts with precision, adjusting lifting speeds based on the weight and dimensions of the part, while avoiding collisions with other equipment or personnel.

- Assembly Line Support: AI cranes can be used to transport parts along complex assembly lines, making real-time adjustments to avoid bottlenecks. The AI system can optimize the timing of part deliveries, improving the efficiency of assembly operations.

- Customizable Movements: In manufacturing plants, the variety of materials and components can make material handling complex. AI cranes are adaptable to different tasks, adjusting movements depending on the size and shape of the item, ensuring safe and efficient handling across a variety of products.

These capabilities make AI cranes an invaluable tool in manufacturing, where precision and efficiency are key to meeting production goals.

automated gantry crane, rail mounted gantry crane with automation for port material handling

Ports and Shipping

Port operations are often hectic and involve handling large containers in tight spaces. AI cranes have become a critical part of port automation, increasing throughput and improving the safety of container handling.

- Container Handling: AI cranes are used in container terminals to automatically load and unload cargo ships. These cranes use AI to predict the best positioning for containers, optimize lifting paths, and adjust operations in real-time based on factors like weather or crane position.

- Port Automation: In busy ports, AI cranes work alongside other automated systems, such as autonomous vehicles and automated guided vehicles (AGVs). They work together to streamline the flow of goods, making the port more efficient and reducing the time ships spend in port.

- Collision Avoidance: AI cranes are equipped with sensors and real-time data processing to prevent accidents by avoiding collisions with other cranes, ships, or equipment. The AI system continuously monitors the environment, making real-time adjustments to ensure safe operations.

In ports, where speed and efficiency are critical to global trade, AI cranes are transforming how goods are handled, making operations faster, safer, and more cost-effective.

Warehouses and Logistics

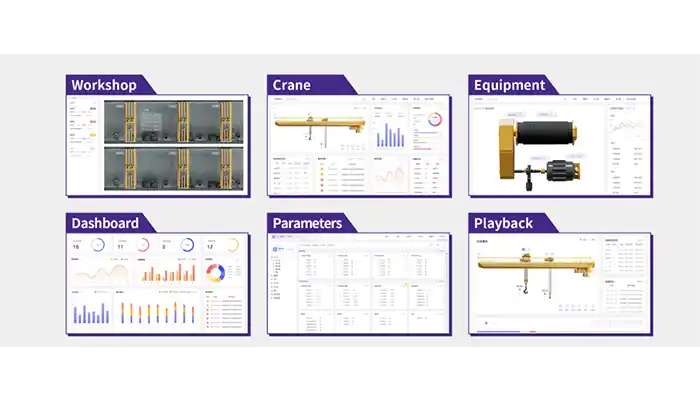

AI cranes are also playing a vital role in warehouses and logistics by streamlining storage, retrieval, and transportation processes. These systems are used to move goods efficiently within large distribution centers or warehouses.

- Storage and Retrieval: AI cranes in warehouses are used to retrieve goods from high shelves or move items to designated locations quickly. By analyzing real-time data, the crane can determine the best path for moving items, optimizing storage space and improving retrieval speed.

- Inventory Management: AI cranes are integrated into inventory management systems, allowing them to track items as they are moved throughout the warehouse. This integration helps with stock control, reducing errors and ensuring that inventory levels are accurately maintained.

- Optimizing Workflows: AI cranes adjust their operations to optimize workflows within the warehouse. They can coordinate with other automated systems, such as automated sorting conveyors, to ensure that goods are moved quickly from one station to another. This reduces human labor and speeds up the overall logistics process.

AI cranes in warehouses not only improve speed and efficiency but also help ensure accuracy in handling and tracking goods, making them a key part of modern logistics operations.

In summary, AI cranes are proving to be indispensable in industries ranging from steel mills to ports and warehouses. Their ability to handle heavy loads, adapt to different environments, and improve operational efficiency makes them a vital tool for modern industrial material handling. As AI technology continues to evolve, we can expect these applications to become even more widespread, driving further improvements in productivity and safety.

Challenges and Considerations for Adopting AI Cranes

While AI cranes offer significant benefits, there are some challenges and considerations to keep in mind when adopting this technology in your operations. Below are the key points to consider:

Initial Investment and Cost

Implementing AI technology in cranes can involve significant upfront costs. While the long-term savings and benefits often outweigh the initial investment, the high price tag can be a barrier for some companies.

- Upfront Costs: AI-enabled cranes typically require advanced sensors, machine learning software, and powerful processing units. These components, along with the crane’s hardware modifications, can drive up the cost compared to traditional overhead cranes. Additionally, installation, integration, and calibration of AI systems can incur further expenses.

- Return on Investment (ROI): While the initial cost may be high, businesses that invest in AI cranes often see a return through increased efficiency, reduced maintenance costs, and fewer accidents. However, it can take time to fully realize the benefits, which requires careful planning and budgeting for the investment.

- Ongoing Maintenance and Upgrades: AI technology requires ongoing maintenance and updates to stay effective. This includes software updates, sensor calibration, and occasional hardware upgrades. While this helps keep the system running smoothly, it also adds to the long-term cost.

Data Integration and Security

AI cranes rely on data from various sensors and systems, which can create challenges in terms of integration and security.

- Data Integration: AI cranes collect data from multiple sources such as weight sensors, motion detectors, cameras, and environmental sensors. Integrating this data into a cohesive system that allows the crane to make intelligent decisions can be complex. The data needs to be processed and analyzed in real time, requiring robust communication networks and data synchronization.

- Data Security: As with any connected technology, AI cranes are susceptible to cyber threats. Protecting the sensitive data transmitted between cranes and central control systems is essential. This means investing in secure networks, encryption, and cybersecurity measures to prevent unauthorized access or manipulation of critical data.

- System Reliability: AI systems must be reliable enough to handle data from different sources and produce accurate, real-time insights. Any delays or errors in data processing could lead to operational disruptions or safety risks, making system reliability a top priority.

Training and Skill Requirements

The adoption of AI cranes also comes with a need for skilled operators and specialized training to ensure the system functions correctly.

- Skilled Operators: Unlike traditional cranes that rely on manual control, AI cranes require operators who understand how to interact with the AI system. These operators need to be familiar with the software interface, how to monitor the system’s performance, and how to intervene in case of issues. This may require a shift in the skill set needed from crane operators.

- Learning Curve: The integration of AI technology into cranes involves a learning curve, both for operators and maintenance personnel. Workers may need training on how to handle new technologies, monitor machine learning outputs, and manage predictive maintenance tasks. This can lead to a temporary slowdown in operations during the training phase.

- Maintenance Skills: AI cranes also require technicians who can perform diagnostics, maintain the system, and troubleshoot any issues that arise. The complexity of AI systems means that traditional maintenance skills may need to be supplemented with knowledge of AI, machine learning algorithms, and data analysis.

Adopting AI cranes presents several challenges, from the significant upfront investment to the complexities of data integration and the need for specialized training. However, these obstacles are not insurmountable. By carefully planning the implementation process, investing in training, and addressing security concerns, businesses can successfully integrate AI cranes into their operations and enjoy the many benefits of improved efficiency, safety, and cost savings in the long run.

The Future of AI Cranes in Material Handling

AI cranes are still in the early stages of their evolution, but the potential for innovation and development is enormous. As technology continues to advance, these cranes will likely become more intelligent, efficient, and integrated into broader industrial systems. Here’s a look at what the future holds for AI cranes in material handling.

Continued Innovation

AI technology is constantly improving, and this trend will undoubtedly continue in the material handling industry.

- Smarter Systems: As AI algorithms evolve, cranes will become increasingly adept at making real-time decisions based on more complex data sets. For example, future AI cranes might use advanced sensors and machine learning to not just optimize lifting and path planning, but also predict how materials will behave in real-world conditions. This would allow them to make even more precise adjustments to their movements, improving efficiency and reducing the risk of accidents.

- Self-Learning Capabilities: Future AI cranes may be able to improve their own performance through machine learning. By continuously analyzing the data they collect, these cranes could learn from their past actions and continuously optimize their movements and efficiency. Over time, AI cranes will require less human intervention, as they’ll be able to handle more tasks autonomously.

- Enhanced Safety Features: Future innovations may bring even more advanced safety systems, such as AI-based collision avoidance, predictive accident prevention, and real-time hazard analysis. These features will make workplaces even safer by reducing the potential for accidents and injuries.

Integration with Other Technologies

AI cranes are likely to become even more powerful when combined with other emerging technologies, creating smarter and more integrated material handling systems.

- Internet of Things (IoT): By connecting cranes to a network of IoT devices, AI cranes will be able to access data from a wide range of sources beyond their own sensors. This could include information on inventory, production schedules, and even environmental factors like temperature or humidity. This integration will allow AI cranes to operate in sync with other automated systems, improving overall efficiency in factories, warehouses, and ports.

- Robotics Integration: AI cranes may work hand-in-hand with robotic systems for tasks such as assembly or sorting. For example, in a manufacturing plant, an AI crane might pick up heavy components and deliver them to robotic arms, which then perform assembly tasks. This level of integration would create a seamless, fully automated system, reducing human labor while enhancing productivity and precision.

- Big Data and Analytics: As AI cranes continue to collect vast amounts of data, integrating this data with big data analytics platforms could unlock new insights into operations. This could help companies forecast demand, optimize workflow, and improve their supply chain management, making material handling even more efficient.

Industry-wide Adoption

As AI cranes continue to prove their value, industry-wide adoption will likely accelerate, especially among early adopters who are eager to stay ahead of the competition.

- Mainstream Acceptance: In the next few years, AI cranes will likely become the norm rather than the exception, particularly in industries that rely heavily on material handling, such as manufacturing, steel production, and logistics. As the technology becomes more affordable and reliable, more companies will make the switch from traditional cranes to AI-driven systems.

- Early Adopter Advantage: Businesses that adopt AI cranes early will have a competitive advantage, benefiting from increased efficiency, cost savings, and safety improvements before their competitors. Early adopters can also gain valuable data and insights that will help them fine-tune their operations and further improve productivity.

- Wider Industry Applications: As AI technology advances, the applications of AI cranes will expand into even more industries. Beyond traditional manufacturing and logistics, AI cranes could be adopted in industries like construction, mining, and even agriculture, where material handling plays a critical role. These industries will also benefit from the efficiency and flexibility that AI cranes bring to the table.

The future of AI cranes in material handling is bright and full of potential. Continued innovation in AI technology will make these cranes even smarter, more efficient, and safer. Their integration with other cutting-edge technologies like IoT, robotics, and big data analytics will create fully automated and optimized material handling systems. As more industries begin to adopt AI cranes, they will become the standard for companies looking to stay competitive and streamline their operations. The future of material handling is undoubtedly intelligent, and AI cranes will be at the forefront of this revolution.

Why Choose Yuantai Crane for Your AI Crane Needs

When it comes to investing in AI cranes, you want a partner who not only understands the technology but also has the expertise to provide tailored, high-performance solutions. At Yuantai Crane, we pride ourselves on being at the forefront of crane innovation, offering cutting-edge AI technology designed to elevate your operations. Here’s why Yuantai Crane is the right choice for your AI crane needs:

Innovation at the Core

At Yuantai Crane, innovation is at the heart of everything we do. We integrate the latest advancements in AI and automation into our crane solutions, ensuring that your operations benefit from the most modern and efficient technology available.

- Advanced AI Integration: We are constantly evolving our crane systems, integrating machine learning algorithms, smart sensors, and real-time data analysis to ensure that every crane we build is at the cutting edge of performance.

- Research and Development: Our in-house research and development team works tirelessly to improve our AI crane technology, ensuring that our clients receive state-of-the-art solutions that are tailored to the specific demands of their industries.

- Future-Proof Solutions: As AI continues to advance, so do our cranes. With Yuantai Crane, you’re not just getting a current solution; you’re getting a system that will evolve with the latest technology and continue to offer value for years to come.

Customized AI Crane Solutions

No two industries are the same, and at Yuantai Crane, we understand that each client has unique needs. That’s why we offer fully customized AI crane solutions that are designed to optimize your specific material handling requirements.

- Tailored to Your Industry: Whether you’re in steel manufacturing, automotive production, or logistics, we work closely with you to design and build AI cranes that are suited to the precise demands of your operations.

- Flexible Design Options: We take into account your facility’s layout, load requirements, safety considerations, and workflow to create a solution that seamlessly integrates into your existing processes, boosting both productivity and safety.

- Scalable Solutions: As your business grows and your needs evolve, our AI cranes are designed with scalability in mind. Whether you need to expand capacity or integrate new technologies, Yuantai Crane is equipped to provide adaptable, future-proof systems.

Long-Term Value

At Yuantai Crane, we’re committed to providing more than just a one-time solution—we’re focused on delivering long-term value for your business. Our AI cranes are built to offer superior performance while ensuring cost-effectiveness over their lifespan.

- Cost-Effective Performance: While the initial investment in AI technology may seem high, our cranes are designed to deliver significant savings in the long run. Through enhanced efficiency, predictive maintenance, and reduced downtime, you’ll see a clear return on your investment.

- Reliability and Durability: Our AI cranes are built to last. With top-tier engineering and rigorous quality control, you can trust that our cranes will perform reliably for years, reducing the need for frequent repairs and replacements.

- Exceptional Customer Support: Our commitment to you doesn’t end with the sale. Yuantai Crane offers ongoing customer support, from installation and training to maintenance and upgrades. Our team is always available to ensure that your AI cranes continue to perform at their best, providing peace of mind for the long haul.

When you choose Yuantai Crane, you’re partnering with an innovative, forward-thinking company that prioritizes your success. With our advanced AI technology, customized solutions, and commitment to long-term value, Yuantai Crane is the ideal partner for all your AI crane needs. Let us help you unlock the full potential of your material handling operations with our cutting-edge AI crane solutions.

Conclusion

AI technology is no longer just a concept of the future—it’s here, and it’s transforming industrial material handling. As industries become more competitive and efficiency-driven, adopting AI cranes is no longer optional but essential for staying ahead. These intelligent cranes offer unparalleled benefits in terms of productivity, safety, and cost savings, making them a game-changer in how materials are handled across various sectors.

By embracing AI, businesses can ensure they’re not just keeping up with industry standards but setting new ones. The future of material handling is here, and those who act now will reap the rewards of early adoption.

If you’re ready to take your operations to the next level, now is the time to explore the transformative power of AI cranes. At Yuantai Crane, we offer tailored AI crane solutions that can revolutionize your material handling processes, boosting efficiency and safety while reducing costs.

Don’t wait for the competition to get ahead—contact Yuantai Crane today and start your journey toward smarter, more efficient material handling. Let us help you lead the way with our innovative AI crane solutions.