Double Hoist Overhead Cranes Case for Poland: Specs & Benefits

Double hoist overhead crane for sale Poland. 6 sets of overhead crane with 2 hoists, European design & low headroom— for efficient industrial lifting.

Introduction

This case study looks closely at six double hoist overhead cranes currently available for sale in Poland. The goal here is simple: to give you a clear understanding of what these cranes offer, how they work, and why they could be a good fit for your lifting and material handling needs.

These six cranes come in three different capacity pairs — 5+5 tons, 10+10 tons, and 12.5+12.5 tons — each designed to handle different scales of industrial work. All feature a European-style double girder design combined with low headroom electric hoists, making them practical for a range of facilities.

Double hoist cranes play an important role in many industries. They allow operators to lift heavier or more awkward loads by using two hoists instead of one, offering greater flexibility and efficiency. Whether it’s manufacturing, steel processing, or warehousing, these cranes help improve workflow and reduce downtime by speeding up load handling and increasing safety.

Key Points:

- Case study focuses on six double hoist overhead cranes available in Poland

- Cranes offered in capacities of 5+5T, 10+10T, and 12.5+12.5T

- European double girder design with low headroom hoists for compact spaces

- Double hoist cranes improve lifting flexibility and efficiency

- Widely used across industries like manufacturing, steel, and warehousing

Technical Specifications of the Six Crane Sets

These six double hoist overhead cranes are built following European engineering standards and are designed with double girder beams for extra lifting strength and long-term durability. The structure is solid, especially for operations that require consistent heavy lifting.

What makes these cranes even more versatile is the use of low headroom electric hoists. These hoists are compact and mounted in a way that reduces the vertical space they take up. That means you can use them even in buildings where ceiling height is limited, without losing valuable lifting range.

Specification Breakdown for Each Set

| Crane Type (T + T) | Bridge Span (m) | Lifting Height (m) | Number of Units |

|---|---|---|---|

| 5 Ton + 5 Ton | 15.19 | 11.74 | 2 units |

| 10 Ton + 10 Ton | 23.68 | 16.56 | 2 units |

| 12.5 Ton + 12.5 Ton | 15.07 | 16.735 | 2 units |

Each pair of cranes is suited to a specific workload and workspace layout.

Main Terms

- Lifting Capacity: The total weight each hoist can handle. For example, a 10+10T crane has two hoists, each rated for 10 tons. You can use them independently or together, depending on how the load is positioned.

- Span: This refers to the width of the crane bridge — essentially how far across the workspace the crane can travel. You’ll want this to match the size of your bay or shop floor.

- Lifting Height: This is the vertical range the hook can travel. It tells you how high you can lift a load off the ground — critical for stacking, loading, or accessing elevated areas.

Why These Specs Are Useful

- If your workflow involves lifting various weights, the dual hoist setup gives you the flexibility to adapt without changing equipment.

- Matching the span to your workshop size helps avoid wasted movement or structural conflicts.

- Knowing your lifting height helps ensure you won’t run into ceiling limits or struggle with low-clearance work.

These specifications aren’t just numbers — they help you plan smarter, install correctly, and avoid paying for crane capacity or coverage you won’t use.

Key Features of the Double Hoist Overhead Cranes

These double hoist overhead cranes come with a mix of smart design choices and heavy-duty components that make them well-suited for real industrial use. Whether you're moving large parts, lifting equipment for assembly, or simply need safe and repeatable hoisting operations, the features listed below support that work reliably.

double girder double hoist overhead crane with 5 ton + 5 ton capacity for sale Poland

double girder double hoist overhead crane with 10 ton + 10 ton capacity for sale Poland

double girder double hoist overhead crane with 12.5 ton + 12.5 ton capacity for sale Poland

Flexible Load Handling with Dual Hoists

The dual hoist setup is one of the biggest advantages of these cranes. Instead of relying on a single hook, you get two lifting points on the same bridge.

- Handle long or unbalanced loads by lifting from both ends simultaneously.

- Lift two separate loads at once, provided they fall within the rated capacity.

- Precise positioning is easier since two hoists offer better control over how the load tilts or turns.

- Ideal for production lines that require synchronized lifting, turning, or tilting during assembly or processing.

This feature adds a level of flexibility that standard single-hoist cranes simply can’t match.

Strong and Reliable Double Girder Design

These cranes are built with a double girder bridge, meaning two parallel beams support the hoisting equipment. This type of construction is preferred when lifting heavier loads or spanning longer distances.

- More lifting power with better weight distribution across the bridge.

- Increased stability under load, reducing sway and improving control.

- Durability for long-term use in demanding environments like steel mills, warehouses, or fabrication shops.

- The double girder also allows the hoist to travel on top of the beams, maximizing hook height.

You won’t find the structure flexing or straining under pressure — it’s designed for industrial-scale work.

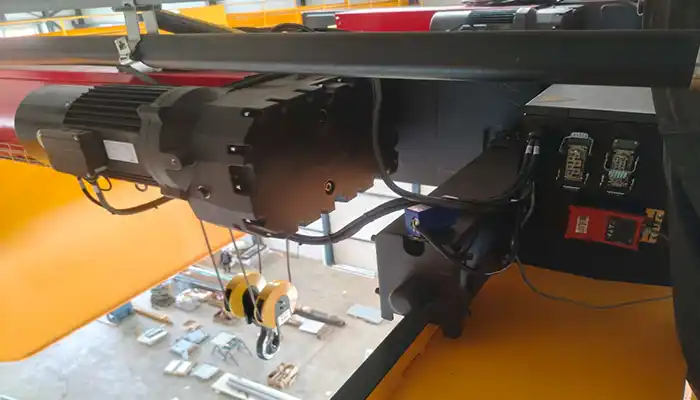

low headroom hoists for double girder cranes

Space-Saving Low Headroom Hoists

Each crane is equipped with low headroom electric wire rope hoists, which help make the most out of available vertical space.

- Compact design reduces the gap between the hoist and the beam, increasing the effective lifting height.

- Suitable for buildings where ceiling height is limited or when you want to maximize stacking height.

- Easy to install in retrofits or existing facilities without needing structural changes.

- Helps avoid unnecessary building modifications just to fit the crane.

These hoists keep the profile low but the performance high — they’re both efficient and smart in tight spaces.

Integrated Safety and Control Systems

These cranes aren’t just strong — they’re also smart and safe. Built-in control and protection systems ensure reliable and predictable operation.

- Limit switches protect against over-travel in both lifting and trolley movement.

- Overload protection prevents the crane from lifting beyond its rated capacity.

- Anti-sway functions and frequency inverters (optional) help with smooth starts and stops.

- Wireless remote controls and cab or pendant options allow operators to control from a safe distance.

Safety features aren’t optional — they’re standard, helping reduce risks during daily use.

Production, Installation, and Commissioning of 6 Sets of Complete Overhead Crane System Solution in Poland

Supplying an overhead crane isn’t just about delivering equipment — it’s about providing a working system from design to handover. In this case, all six double hoist overhead cranes were not only built to spec but also installed and commissioned in Poland with full consideration of site conditions and client needs. Below is a breakdown of the full process, from factory floor to customer operation.

Precision Manufacturing with Focus on Quality and Standards

All six cranes were manufactured in our facility using strict quality control procedures, advanced production equipment, and compliance with European standards.

- Double girder steel structures were fabricated using CNC-controlled machines to ensure accuracy in dimensions and welding.

- Low headroom electric hoists were assembled and pre-tested in-house for alignment, motor function, and safety features.

- Components such as limit switches, motors, gearboxes, and electrical panels were sourced from reliable brands and tested before shipment.

- Full load testing and trial runs were conducted in the factory before dispatch to confirm lifting performance and motion control.

By the time the cranes leave the factory, they are fully assembled, tested, and ready for site integration — reducing installation time on the customer’s end.

Installation Adapted to Polish Site Requirements

Once the equipment arrived in Poland, our installation team worked closely with the local crew and customer representatives to ensure a smooth setup process.

- On-site inspection was done before the start of installation to confirm building conditions (runway beams, clearance, power supply access).

- Cranes were lifted and assembled section by section using mobile cranes and rigging systems, ensuring safe handling.

- Runway alignment and end stop positioning were checked using laser levels for accurate crane travel.

- Electrical wiring, control panels, and hoist connections were installed in accordance with Polish safety codes.

The installation was carried out in active industrial facilities, so downtime was minimized through staged work schedules.

Commissioning, Load Testing, and Operator Training

Before the cranes could be handed over for use, a full commissioning process was carried out for each of the six sets.

- No-load and full-load testing was completed for each hoist, verifying lifting speed, brake response, and emergency stop function.

- Motion synchronization tests for dual hoist operation ensured stable and balanced lifting.

- System diagnostics checked limit switches, control logic, and inverter performance.

- Polish operators received on-site training, including safety routines, basic troubleshooting, and control procedures (remote and pendant).

- A final handover checklist was signed off with the client to confirm all equipment and documentation were in order.

This step is critical. It’s not enough to just install the crane — it must also perform reliably under real working conditions and be safe for operators to use from day one.

Benefits to Complete Overhead Crane System Solution for Buyers

Investing in a complete crane system isn’t just about buying equipment — it’s about solving a handling problem in the most efficient and sustainable way. For buyers in Poland, especially those managing multiple production lines or large-scale workshops, this package of six double hoist overhead cranes offers clear, long-term value.

Streamlined Purchasing with Standardized Specifications

When you purchase multiple cranes with the same structure, hoist configuration, and electrical system, everything becomes easier — from installation to daily operation.

- Same spare parts and hoist models across all cranes simplify inventory and reduce the chance of mismatch during maintenance.

- Operators and technicians only need to be trained once, since the controls, safety features, and routines are identical.

- Faster troubleshooting as maintenance teams become familiar with one system instead of multiple variations.

- Unified documentation (manuals, wiring diagrams, testing protocols) reduces administrative workload.

It’s a smart way to scale your lifting capacity without overcomplicating your operations.

Cost-Effectiveness and Better Operational Efficiency

Buying a package of six cranes at once — all configured to a consistent design — can offer real financial and time savings.

- Bulk pricing opportunities help reduce the cost per unit compared to ordering one crane at a time.

- Shorter lead times because all units are manufactured and tested together.

- Shared commissioning process lowers overall service and travel expenses for setup engineers.

- Efficiency gains in layout design, as all cranes can work in synchronized environments or backup each other during peak load periods.

It’s not just cheaper — it’s smarter in how it improves workflow across your facility.

Local Support and Service for Polish Buyers

For buyers in Poland, service availability plays a huge role in the decision-making process. After-sales support is not an afterthought — it’s part of the system solution.

- We provide remote technical assistance, as well as the option to work with local service partners familiar with our cranes.

- Spare parts shipments are organized efficiently with documentation prepared for EU customs compliance.

- Optional preventive maintenance packages and regular inspection services can be arranged to meet Polish industrial safety requirements.

The goal is to keep your crane systems running smoothly without interruption or unnecessary downtime.

Long-Term Reliability and Easy Maintenance

These cranes are designed to run reliably for years with minimal intervention, assuming basic maintenance is performed.

- European-style electric hoists are known for durability, smooth control, and long service life.

- All structural steel is treated and coated for corrosion resistance, suitable for industrial environments.

- Modular design makes it easier to replace parts like wire ropes, brake pads, or control units without special tools.

- Built-in diagnostics in the control panel help detect minor issues early, avoiding major breakdowns later.

For operations where downtime means lost revenue, this kind of reliability is a key selling point.

Summary and Send Us an Inquiry: Double Hoist Overhead Cranes in Poland

Choosing a crane system is about solving your real-world handling needs with a solution that lasts. The six double hoist overhead cranes now ready for use in Poland combine strength, versatility, and efficient design. For companies with demanding lifting tasks and plans for long-term reliability, these cranes are well worth considering.

Quick Recap: What’s Included?

Each crane in this offering was built with real industrial requirements in mind. Here’s a clear breakdown of what’s available:

Three double hoist models:

- 5 + 5 ton cranes with a 15.19-meter span and 11.74-meter lifting height (2 sets)

- 10 + 10 ton cranes with a 23.68-meter span and 16.56-meter lifting height (2 sets)

- 12.5 + 12.5 ton cranes with a 15.07-meter span and 16.735-meter lifting height (2 sets)

European-style design throughout:

- Strong and stable double girder structure

- Low headroom electric hoists for better use of vertical space

- Dual hoist points for flexible lifting of long or unbalanced loads

Key features for industrial operations:

- Ideal for steel processing, mechanical assembly, and equipment handling

- Designed for high-frequency use in busy environments

- Built-in safety and electrical control systems for smooth and secure operation

Why It’s Worth Reaching Out

If you're working on a facility expansion, equipment upgrade, or starting a new production line, this crane package offers real value.

- Standardized crane sets reduce design and training costs

- Bulk purchasing lowers unit cost and speeds up delivery

- Reliable after-sales service for clients in Poland and across Europe

- Simplified spare parts management and easier technical support

Whether you're an engineer looking to meet a technical spec or a buyer comparing quotes, we’re ready to help.

How to Get in Touch and Start Your Inquiry

We welcome inquiries from facility managers, equipment buyers, consultants, and industrial users. Here's what you can do next:

- Share your lifting requirements such as capacity, span, and height

- Ask for drawings, technical data sheets, or layout suggestions

- Request a quotation tailored to your working conditions

To begin the conversation, simply send us an email, call our office, or visit our website. Our team is ready to help with practical advice, pricing, and technical support.