2 Ton Jib Crane for Sale in UAE for Oil and Gas Industry

Customized 2-ton jib crane solution enhancing lifting efficiency, safety, and reliability for UAE oil and gas workshops.

Case Study Outline: 2 Ton Jib Crane for Sale in UAE for Oil and Gas Industry

This case study shares how we provided two 2-ton jib cranes to a customer in the United Arab Emirates.

The client works in the oil and gas industry, where safe and efficient lifting equipment is essential. They needed compact lifting solutions for handling parts and tools within their workshop.

We supplied two BZ-type pillar jib cranes, each paired with an electric chain hoist. One had a 4.9-meter arm, and the other had a 5.3-meter arm, both with a 4.5-meter lifting height. The cranes run on 380V, 50Hz, 3-phase power, which matches the local supply in the UAE.

The customer wanted:

- Easy-to-use cranes that could fit in tight spaces.

- Reliable lifting for daily operations.

- Simple installation and low maintenance.

We delivered the cranes on time, fully customized to their working conditions. Both units were tested before shipping and packed for export to meet UAE import standards.

The result?

- The cranes are now running smoothly in the client's workshop.

- The client is happy with the quality and prompt support.

- We’re now in talks about another project.

This is a simple story of listening to the customer’s real needs and delivering exactly what fits.

2 ton jib crane for sale, Cusotmized floor mounted jib crane for sale

Client Background

The client for this project is Ms. Feng Nana, a procurement officer handling equipment sourcing for an oil and gas service company in the United Arab Emirates. She contacted us on behalf of her technical team, who were responsible for maintaining and upgrading their workshop’s lifting systems.

Location

The client's facility is located in Abu Dhabi, one of the key centers for oil and gas operations in the UAE. This particular site is part of a technical maintenance yard that provides support services for nearby oilfields and refineries. The workshop handles a mix of heavy tools, machine components, and spare parts that are constantly moved, repaired, or replaced.

Industry and Workshop Environment

They work in the onshore oil and gas sector, mainly in equipment servicing and parts refurbishment. The workshop isn’t a large factory—it’s more of a medium-sized service center, but with high demands on daily material handling.

- Most of the components lifted range from 300 kg up to 1.5 tons.

- Frequent lifting of valves, fittings, gearbox housings, flanges, and pipe spools.

- Movement of items between workbenches, welding tables, and inspection areas.

- Limited floor space and fixed columns in the building layout.

Their operations require reliable lifting tools that don’t take up much space but offer full functionality for lifting, rotating, and placing heavy parts exactly where needed.

Purpose of Procurement

The client had a few clear goals when sourcing the jib cranes:

- Reduce manual lifting: Workers were previously using chain blocks or forklifts, which was time-consuming and risked injury.

- Improve safety: They wanted stable and controlled lifting, especially for awkward or off-center loads.

- Optimize workflow: The team needed a crane that could handle quick lifting tasks without interrupting other operations.

- Match power standards: The cranes had to operate on 380V/50Hz/3-phase, the standard industrial power supply in Abu Dhabi.

They weren’t looking for a one-size-fits-all crane—they wanted something that could be customized to their space and working needs, yet still easy to install and use. That’s what led them to choose pillar-mounted 2-ton jib cranes with chain hoists.

Client Requirements

Before placing the order, the client provided us with a clear set of technical requirements. These were based on their actual workshop layout and daily operational needs in the oil and gas sector.

Lifting Capacity: 2 Ton

- The maximum load they handle in the workshop is about 1.5 tons, but they wanted a 2-ton capacity to add safety margin and flexibility.

- Loads include equipment like pumps, valve assemblies, and metal structures that need lifting and rotation during service work.

Jib Arm Lengths: 4.9 Meters and 5.3 Meters

The client needed two different jib cranes, one with a 4.9m reach and another with 5.3m.

These lengths were carefully selected based on:

- Distance between workstations.

- Location of pillars or walls in the workshop.

- The need for full coverage of the work area without the arm hitting obstructions.

The rotating jib arm allows them to swing loads between machines, benches, and storage racks smoothly.

Lifting Height: 4.5 Meters

The workshop has a moderate ceiling height, but enough clearance to allow a 4.5-meter lifting height.

This height allows them to:

- Lift equipment directly from the floor or pallets.

- Position parts at working height on service tables or assembly platforms.

We double-checked to make sure the hoist hook height fits well with the jib and column design.

Power Supply: 380V / 50Hz / 3-Phase

- The facility uses standard industrial voltage in the UAE—380V, 50Hz, 3-phase.

- We configured the hoists accordingly, so there’s no need for voltage conversion or adjustments on-site.

Hoist Type: Electric Chain Hoist

The client preferred electric chain hoists for a few reasons:

- Compact and lightweight.

- Simple structure and easy maintenance.

- Suitable for intermittent use throughout the day.

Each hoist includes upper and lower limit switches, an overload protection system, and pendant control with a long cable to operate at a safe distance.

Working Environment: Standard Zone

- The client confirmed that the workshop is in a non-hazardous zone, so explosion-proof equipment was not required.

- However, they did ask for good protection against dust, heat, and occasional outdoor air, which is common in UAE’s industrial zones.

Usage Frequency: Daily but Light-Duty

- The cranes are used several times per day, mostly for short-duration lifting tasks.

- Not 24/7 or high-cycle usage, but enough to require stable performance and reliability.

- Their main focus was to have cranes that are ready to use anytime, without complex startup or long preparation.

Proposed Solution

Based on the client’s needs, we provided a complete jib crane system built for safe, simple, and reliable operation in their oil and gas workshop. cantilevers of 2 ton jib cranes

cantilevers of 2 ton jib cranes  columns of 2 ton flloor mounted jib crane

columns of 2 ton flloor mounted jib crane

Crane Type: BZ-Type Pillar-Mounted Jib Crane

- We offered the BZ-type pillar jib crane, which is one of the most popular models for workshop use.

- It’s floor-mounted, stable, and requires no ceiling support — perfect for spaces with fixed steel structures or limited headroom.

- The design allows for easy installation and long-term use without much maintenance.

Hoisting Equipment: Electric Chain Hoist

Each jib crane is equipped with a 2-ton electric chain hoist, selected for its:

- Compact size, ideal for limited space.

- Upper and lower limit switches to prevent over-travel.

- Overload protection for safety and to avoid damage.

- Pendant control with a long cable, giving the operator a safe working distance.

The hoist was matched to the crane arm and lifting height to ensure smooth vertical and horizontal movement.

Customization Highlights

We didn’t offer a standard model. Instead, we customized key parts of the crane to match the actual worksite conditions:

- Arm Rotation: One crane was designed for 270° rotation, while the other had 360° full rotation to cover more working space.

- Foundation Plate: The base plates were adjusted for anchoring into UAE’s soil and concrete standards. We provided detailed foundation drawings for proper installation by the local civil team.

- Weather Resistance: Although the cranes are used indoors, the client asked for dust protection and anti-corrosion paint, since the workshop is semi-open and exposed to desert air.

Certifications

We included all necessary certifications to support import and compliance:

- CE certification for machinery safety.

- ISO 9001 for quality management systems.

- Third-party inspection reports (optional) provided before shipment upon client’s request.

Additional Support

To make things smooth for the installation and startup, we also provided:

- A detailed installation manual with foundation instructions.

- A user-friendly operation manual in English.

- Remote technical support via video or phone during installation or setup.

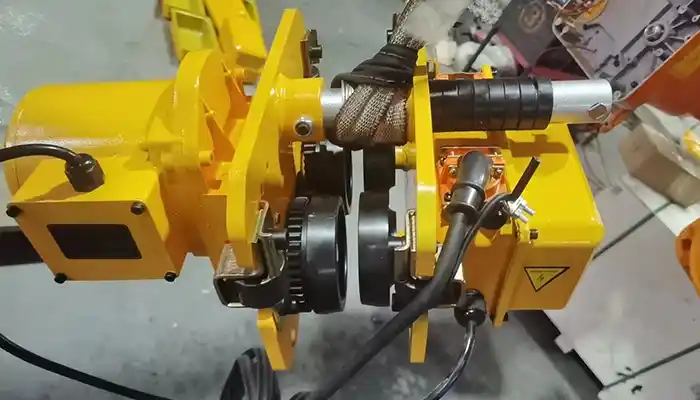

We also labeled all hoist parts and electrical cables clearly, making it easier for the local team to connect and test the crane quickly. Electric hoist trolley

Electric hoist trolley  2 ton electric chain hoist for sale

2 ton electric chain hoist for sale  Electric hoist pendant control

Electric hoist pendant control

Manufacturing & Quality Assurance

After confirming the specifications, we started production right away. Our team followed strict quality control standards to make sure everything met both the client’s expectations and international safety requirements.

Production Process and Lead Time

- The jib cranes were custom-fabricated in our workshop in Xinxiang, China.

- Main parts like the pillar column, rotating arm, and foundation plate were cut, welded, and machined with CNC precision.

- The electric chain hoists were assembled and tested separately before integration.

- Final assembly and alignment checks were done before painting.

The full production took about 18 working days, followed by 3–5 days for quality testing and packing.

Factory Testing Before Shipment

We performed a complete factory test on both jib cranes before shipment. Key testing points included:

- Static and dynamic load test: Each crane was tested at 125% of rated load (2.5 tons) to confirm strength and stability.

- Rotation function test: We checked the smoothness and range of rotation (270° and 360°) to ensure no mechanical blockages.

- Electrical safety test: We tested all control components — including the hoist pendant, limit switches, and overload protection — for proper function.

- All testing was documented with photos and videos, which were shared with the client before packing.

Packing and Shipping for UAE Compliance

We packed all components with care to avoid any damage during long-distance transport:

- Steel structures were wrapped with anti-rust coating and protected with plastic film.

- Hoists and electrical parts were placed in plywood cases, cushioned and labeled properly.

- Each part was marked with a matching drawing code, making it easy to identify during installation.

We also ensured full compliance with UAE import standards—including heat-treated wooden packaging and the required shipping documents like packing list, commercial invoice, and CE certificate copies.

Delivery & Logistics

Once production and quality checks were complete, we moved quickly to arrange delivery that fit the client’s schedule and logistics preferences.

Delivery Timeline and Incoterm

- The cranes were ready for shipment within 25 days after order confirmation.

- We agreed on the CIF Dubai Incoterm with the client. This means we took responsibility for delivering the cranes safely to the port in Dubai, covering shipping and insurance.

- The client handled customs clearance and inland transport from Dubai to their workshop.

Shipping Method

Both jib cranes and hoist units were carefully packed to fit into a 20-foot standard shipping container.

Using container shipping ensured:

- Secure transport with minimal movement.

- Protection from harsh sea weather and handling damage.

- Cost-effective consolidation of parts and accessories.

The container was sealed and tracked from our factory to the Dubai port.

Export Documentation and Customs Support

To ensure smooth customs clearance in the UAE, we provided all necessary documents, including:

- Commercial Invoice with detailed product descriptions and values.

- Packing List showing all parts and their weights.

- Bill of Lading issued by the shipping company.

- CE and ISO certificates proving compliance with safety and quality standards.

- Test reports and inspection certificates verifying the cranes’ condition before shipment.

- Certificate of Origin for customs tariffs and import procedures.

We also supported the client by:

- Answering customs-related questions promptly.

- Providing any extra documentation needed for local regulations.

- Coordinating with the freight forwarder to handle any shipment updates.

This delivery plan helped the client receive their cranes on time and with no hassle at customs. Let me know if you want to continue with the next section!

Outcome & Client Feedback

The project concluded smoothly, meeting all client expectations from delivery to operation.

On-Time Delivery and Successful Installation

- The cranes arrived in Dubai right on schedule, about 30 days after order confirmation.

- The client’s local team completed installation quickly using our detailed manuals and remote support.

- No major issues were reported during installation or initial testing.

- The cranes were fully operational within a week of arrival, ready for daily use in their workshop.

Client Satisfaction with Performance and Support

- The client praised the smooth rotation and precise lifting control of the jib cranes.

- The electric chain hoists performed reliably, making lifting tasks faster and safer.

- Workers reported a noticeable reduction in manual effort and improved workflow.

- The client also appreciated our timely communication and technical support throughout the process.

- They especially valued the customized foundation design that matched their workshop conditions perfectly.

Future Cooperation and Repeat Orders

- Encouraged by this successful project, the client expressed interest in ordering additional cranes for other service yards.

- They requested us to provide solutions for heavier loads and longer jib arms in the future.

- Our team has already started discussing possible upgrades and maintenance contracts to support their expanding operations.

Conclusion

This 2-ton jib crane solution proved to be a great fit for the UAE’s oil and gas industry. It combines strength, flexibility, and safety — all tailored to the client’s unique workshop conditions.

Why This 2-Ton Jib Crane is Ideal for UAE’s Oil & Gas Sector

- It offers reliable lifting capacity that matches typical equipment sizes in oil and gas workshops.

- The customizable jib arm lengths and rotation angles give operators full coverage and easy maneuvering in tight spaces.

- The durable build and weather-resistant features stand up well to UAE’s harsh climate.

- Its electric chain hoist ensures smooth, controlled lifting with built-in safety features.

Key Takeaways for Buyers

- Don’t just buy a standard crane—think about your local site conditions, power supply, and work environment.

- Customization matters: from foundation design to rotation range, every detail counts.

- Ask for clear certifications and factory testing to ensure quality and compliance.

- Support and documentation from the supplier make installation and operation much easier.

Yuantai Crane’s Commitment

At Yuantai Crane, we understand the challenges faced by clients in demanding industrial sectors like oil and gas. We’re committed to delivering safe, efficient, and customized lifting solutions that help our clients work smarter and safer — no matter where they are in the world.