Single Girder Gantry Crane

Double Girder Gantry Crane

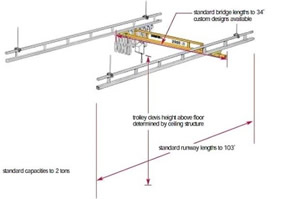

Portable Gantry Crane

Rubber Tyred Crane

Tonnages & Specifications

Hot Sale Gantry Crane Price & Cost

Philippines

Pakistan

Saudi Arabia

UAE

Malaysia

Overhead Crane Nigeria

Kenya

South Africa

UK

Jamaica

Kuwait

Azerbaijan

Trinidad and Tobago

Poland

Canada

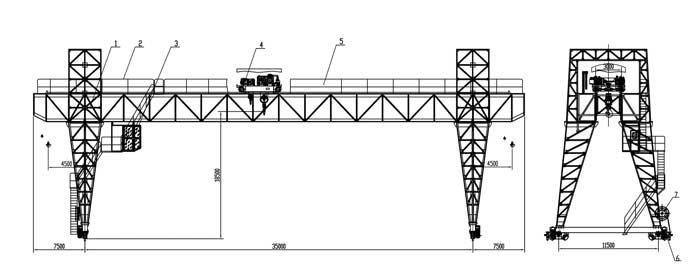

Truss type double girder gantry crane

Truss type double girder gantry crane

Truss girder - main parts and componets of double girder truss gantry crane

Truss girder - main parts and componets of double girder truss gantry crane Gantry trolley - main parts and componets of double girder truss gantry crane

Gantry trolley - main parts and componets of double girder truss gantry crane Gantry crane driving motor- main parts and componets of double girder truss gantry crane

Gantry crane driving motor- main parts and componets of double girder truss gantry crane Crane hook - main parts and componets of double girder truss gantry crane

Crane hook - main parts and componets of double girder truss gantry crane Double girder truss gantry crane applications

Double girder truss gantry crane applications Double girder truss gantry crane for construction site

Double girder truss gantry crane for construction site Double girder truss gantry crane for construction

Double girder truss gantry crane for construction Double girder truss gantry crane for road construction

Double girder truss gantry crane for road construction Single girder truss gantry crane

Single girder truss gantry crane  Double girder truss gantry crane

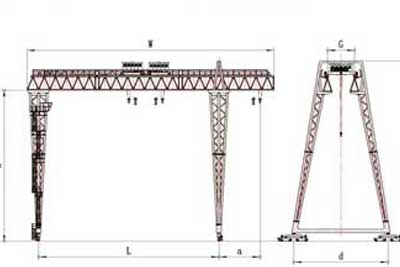

Double girder truss gantry crane Truss gantry crane with on cantilever

Truss gantry crane with on cantilever  Truss gantry crane with no cantilever

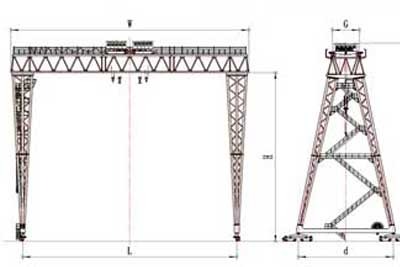

Truss gantry crane with no cantilever