5 Ton 10 Ton Overhead Cranes for Cashmere Processing Plant

Overhead Cranes Material Handling Efficiency in Cashmere Processing Plant

Cashmere processing involves a series of intricate steps, each crucial for maintaining the quality and integrity of the delicate fibers. From the moment raw cashmere is harvested from the undercoat of cashmere goats to its transformation into luxurious garments, material handling plays a pivotal role.

Material handling encompasses the movement, storage, and control of cashmere fibers throughout the processing journey. This includes tasks such as sorting, cleaning, dehairing, spinning, and weaving or knitting. Each stage demands careful attention to detail to ensure that the cashmere retains its softness, warmth, and premium quality.

Efficient material handling is essential for optimizing the production process, reducing waste, and meeting the growing demand for highquality cashmere products worldwide.

Importance of Efficiency in Cashmere Processing

- In the competitive landscape of luxury textiles, efficiency is not just a goal; it's a necessity. Cashmere processing facilities face increasing pressure to streamline operations, minimize costs, and deliver products of the highest quality to meet customer expectations.

- Efficient material handling directly impacts the overall productivity and profitability of cashmere processing operations. By optimizing workflows, reducing handling times, and minimizing errors, manufacturers can enhance their competitive edge while maintaining the superior quality and consistency that define luxury cashmere products.

- Furthermore, efficient material handling practices contribute to sustainability efforts by minimizing energy consumption, reducing waste, and lowering environmental impact throughout the production process.

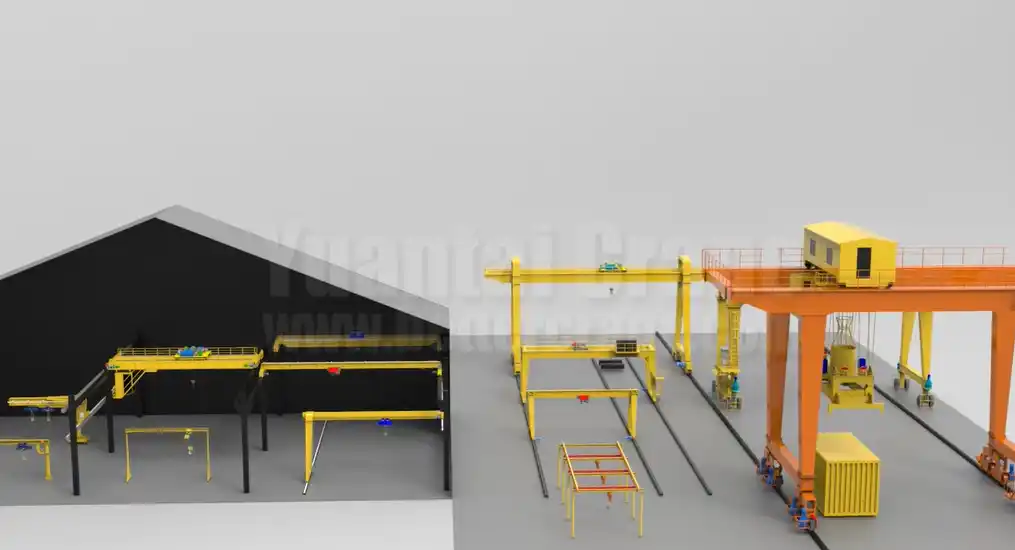

Overhead cranes are a cornerstone of modern material handling solutions, offering versatility, precision, and efficiency in a wide range of industrial applications, including cashmere processing. These robust machines are typically mounted on tracks or beams above the production floor, allowing them to move horizontally and vertically with ease. Equipped with hoists and trolleys, overhead cranes can lift, transport, and position heavy loads with exceptional precision and control.

In the workshop of cashmere processing, overhead cranes play a vital role in optimizing material handling workflows, enabling manufacturers to maximize efficiency, ensure product quality, and enhance workplace safety. With customizable features and advanced automation capabilities, overhead cranes offer a tailored solution to the unique challenges of handling delicate cashmere fibers with care and precision.

Cashmere Processing

Overview of Cashmere Fibers and their Value

Cashmere fibers are renowned for their exceptional softness, warmth, and luxurious feel, making them highly sought after in the textile industry. These fine fibers are harvested from the undercoat of cashmere goats, which are primarily found in regions with harsh climates, such as Mongolia, China, and Iran. What sets cashmere apart from other types of wool is its unique structure. Cashmere fibers are extremely fine and delicate, measuring just a few micrometers in diameter. This gives cashmere its incomparable softness and insulation properties, making it an ideal choice for premiumquality garments and accessories. Due to the laborintensive nature of cashmere production and the limited supply of raw materials, genuine cashmere products command a premium price in the market. The value of cashmere fibers lies not only in their physical properties but also in the craftsmanship and expertise required to process them into finished goods.

Key Stages in Cashmere Processing

Sorting and Cleaning

- The first stage of cashmere processing involves sorting and cleaning the raw fibers to remove any impurities and foreign matter. This is typically done by hand, as each batch of cashmere must be carefully inspected to ensure uniformity and quality. Workers meticulously sort the fibers based on their color, length, and fineness, discarding any coarse or discolored fibers.

- Once sorted, the cashmere fibers are washed using gentle detergents to remove dirt, grease, and other contaminants. This step is crucial for preparing the fibers for further processing and ensuring the purity of the final product.

Dehairing

- Dehairing is the process of separating the fine cashmere fibers from the coarser guard hairs that make up the outer coat of the cashmere goat. This is typically done using mechanical or chemical methods, which help to isolate the desired cashmere fibers while removing unwanted impurities.

- Mechanical dehairing involves passing the raw cashmere through a series of specialized machines that comb and separate the fibers based on their diameter and length. Chemical dehairing, on the other hand, utilizes gentle enzymes or detergents to dissolve the outer hairs while preserving the delicate cashmere fibers.

Spinning

- Once the cashmere fibers have been sorted and cleaned, they are ready for spinning, where they are transformed into yarn suitable for weaving or knitting. Spinning can be done using traditional spinning wheels or modern spinning machines, depending on the scale and requirements of the production facility.

- During spinning, the cashmere fibers are twisted together to create a continuous thread or yarn with the desired thickness and texture. This process requires precision and expertise to ensure uniformity and consistency in the final product.

Weaving or Knitting

- The final stage of cashmere processing involves weaving or knitting the spun yarn into finished fabrics or garments. This can be done using traditional looms for weaving or specialized knitting machines for knitting. The choice of weaving or knitting technique depends on the desired fabric structure, design, and enduse application.

- Once woven or knitted, the cashmere fabric undergoes finishing processes such as dyeing, blocking, and pressing to enhance its appearance and properties. The finished cashmere products are then inspected for quality and packaged for distribution to retailers or consumers, ready to be enjoyed for their exceptional softness and luxury.

Challenges in Material Handling in Cashmere Processing

Delicate Nature of Cashmere Fibers

- Cashmere fibers possess an exquisite softness and delicacy that set them apart from other types of wool. However, this very quality also presents a significant challenge in material handling. Cashmere fibers are extremely fine and fragile, prone to breakage, tangling, and damage if handled improperly.

- The delicate nature of cashmere fibers requires careful attention throughout the processing journey to minimize the risk of fiber breakage, pilling, and matting. Any rough handling or excessive tension can result in irreversible damage, compromising the quality and integrity of the final product.

- Therefore, material handling equipment and processes must be tailored to accommodate the unique properties of cashmere fibers, providing gentle and precise handling to preserve their softness and loftiness.

Need for Precision and Care in Handling

- Precision and care are paramount in handling cashmere fibers effectively. Unlike coarser wool fibers, which may withstand rough handling to some extent, cashmere requires a more delicate touch to maintain its pristine condition.

- Each stage of cashmere processing, from sorting and cleaning to spinning and weaving, demands meticulous attention to detail to ensure consistent quality and performance. This requires skilled labor and specialized equipment capable of providing precise control and gentle handling of the delicate fibers.

- Moreover, the high value of cashmere products further underscores the importance of precision and care in material handling. Any damage or defects incurred during handling can result in significant financial losses and damage to brand reputation.

Labor Intensive Processes

- Cashmere processing is inherently laborintensive, requiring manual intervention and skilled craftsmanship at various stages of production. From handsorting raw fibers to operating spinning and weaving machines, human labor remains integral to the cashmere processing industry.

- The laborintensive nature of cashmere processing presents several challenges, including increased production costs, reliance on skilled workers, and potential bottlenecks in the production workflow. Moreover, manual handling of cashmere fibers may introduce variability and inconsistency in the final product, requiring stringent quality control measures to maintain product standards.

- To address these challenges, manufacturers may explore automation and mechanization solutions to streamline production processes, reduce labor costs, and improve efficiency without compromising product quality. However, the delicate nature of cashmere fibers necessitates careful consideration of automation options to ensure compatibility with the unique requirements of cashmere processing.

The Role of Overhead Cranes in Optimizing Material Handling

Introduction to Overhead Cranes

- Overhead cranes are versatile material handling solutions that play a crucial role in optimizing efficiency and productivity in various industries, including cashmere processing. These robust machines are typically mounted on tracks or beams above the production floor, providing vertical and horizontal movement capabilities to lift, transport, and position heavy loads with precision and ease.

- Overhead cranes consist of several key components, including a bridge, hoist, trolley, and controls. The bridge spans the width of the working area, supported by end trucks that move along rails or beams. The hoist, attached to the bridge, is responsible for lifting and lowering loads, while the trolley allows for horizontal movement along the bridge.

- With their ability to handle heavy loads safely and efficiently, overhead cranes offer a reliable solution for material handling tasks in cashmere processing facilities, where delicate fibers require gentle yet precise handling.

Advantages of Overhead Cranes in Cashmere Processing

Precision Handling

- One of the primary advantages of overhead cranes in cashmere processing is their ability to provide precision handling of delicate fibers. The adjustable speed and control features of overhead crane systems allow operators to maneuver loads with exceptional accuracy, minimizing the risk of damage or contamination to cashmere fibers.

- Whether lifting raw cashmere bales, transferring materials between processing stages, or positioning equipment for spinning and weaving, overhead cranes ensure precise placement and movement, optimizing workflow efficiency and maintaining product quality.

Increased Efficiency and Productivity

- Overhead cranes contribute to increased efficiency and productivity in cashmere processing facilities by streamlining material handling processes and reducing downtime. With their ability to lift and transport heavy loads quickly and safely, overhead cranes expedite material flow, minimizing bottlenecks and maximizing throughput.

- By automating repetitive or laborintensive tasks, such as loading and unloading raw materials or moving finished products for packaging and distribution, overhead cranes allow operators to focus on more valueadded activities, further improving overall productivity and profitability.

Safety Benefits

- Safety is paramount in cashmere processing, where workers must handle delicate fibers and operate machinery in close proximity. Overhead cranes enhance workplace safety by reducing the need for manual lifting and handling of heavy loads, minimizing the risk of musculoskeletal injuries and accidents.

- Additionally, overhead cranes feature builtin safety mechanisms, such as overload protection, emergency stop controls, and collision avoidance systems, to prevent accidents and ensure the wellbeing of workers and equipment. By promoting a safer work environment, overhead cranes help to reduce absenteeism, worker turnover, and associated costs, while enhancing employee morale and satisfaction.

Customizations for Cashmere Processing

Specialized Attachments

- Overhead cranes can be equipped with specialized attachments tailored to the unique requirements of cashmere processing. For example, softtouch lifting devices or vacuum lifters can be used to handle delicate cashmere fibers without causing damage or distortion.

- Additionally, customdesigned spreader bars or lifting beams can accommodate irregularly shaped loads, such as raw cashmere bales or finished garment rolls, providing secure lifting and transport solutions while minimizing the risk of accidents or product damage.

Automation and Integration with Production Lines

- Overhead cranes offer opportunities for automation and integration with cashmere processing production lines, further enhancing efficiency and productivity. Automated crane systems can be programmed to perform repetitive tasks, such as material handling or equipment positioning, with minimal human intervention, allowing operators to focus on more complex or strategic activities.

- Moreover, integration with production line machinery, such as spinning or weaving equipment, enables seamless material flow and process synchronization, reducing cycle times and optimizing overall production output. By leveraging the capabilities of overhead cranes for automation and integration, cashmere processing facilities can achieve higher levels of operational efficiency, costeffectiveness, and competitiveness in the global marketplace.

Comparative Analysis: Overhead Cranes vs. Traditional Handling Methods

To demonstrate the benefits of overhead cranes in cashmere processing, let's compare them with traditional handling methods:

Traditional Handling Methods:

Manual lifting and transport of raw materials and finished products

High risk of worker injuries and product damage

Limited efficiency and productivity due to manual labor constraints

Lack of precision and control in material handling processes

Overhead Cranes:

Automated lifting and transport of materials with precision and accuracy

Reduced risk of accidents and injuries through advanced safety features

Increased efficiency and productivity through automation and optimization of material flow

Customizable attachments and integration capabilities for tailored solutions to specific handling needs

Comparative analysis shows that overhead cranes offer significant advantages over traditional handling methods in cashmere processing, including improved safety, efficiency, and productivity. By investing in overhead crane technology, manufacturers can enhance their competitive edge and position themselves for success in the dynamic textile industry.

Best Practices for Implementing Overhead Cranes in Cashmere Processing

Assessing Facility Requirements and Constraints

Before implementing overhead cranes in cashmere processing facilities, it's essential to conduct a thorough assessment of facility requirements and constraints. This includes evaluating factors such as available space, layout, ceiling height, and structural considerations. Additionally, consider the specific material handling needs and workflows of the facility to determine the optimal placement and configuration of overhead crane systems. By understanding facility requirements and constraints upfront, you can ensure that overhead crane installations are tailored to meet the unique needs of the cashmere processing operation.

Selecting the Right Type and Capacity of Overhead Crane

Choosing the right type and capacity of overhead crane is critical for optimizing material handling efficiency in cashmere processing. Consider factors such as load weight, size, and frequency of lifts when selecting overhead crane systems. For cashmere processing applications, lightweight and maneuverable overhead cranes with softtouch lifting attachments are often preferred to ensure gentle handling of delicate fibers. Additionally, assess whether a singlegirder or doublegirder overhead crane configuration is more suitable for the facility layout and material handling requirements. By selecting the right type and capacity of overhead crane, you can maximize productivity and minimize the risk of equipment overload or inefficiency.

Training and Safety Protocols

Training and safety protocols are essential for ensuring the safe and efficient operation of overhead cranes in cashmere processing facilities. Provide comprehensive training to crane operators on proper operation, maintenance, and safety procedures. Emphasize the importance of load capacity awareness, load stability, and proper load attachment techniques to prevent accidents and injuries. Additionally, establish clear safety protocols for working around overhead crane systems, including guidelines for pedestrian traffic, signaling, and emergency procedures. Regularly review and reinforce safety practices to maintain a safe working environment and minimize the risk of incidents or downtime.

Maintenance and Upkeep

Proper maintenance and upkeep are vital for maximizing the lifespan and performance of overhead crane systems in cashmere processing facilities. Implement a proactive maintenance schedule that includes routine inspections, lubrication, and component replacement as needed. Address any signs of wear, damage, or malfunction promptly to prevent equipment failure and downtime. Additionally, provide ongoing training to maintenance personnel on troubleshooting and repair techniques to ensure timely resolution of issues. By prioritizing maintenance and upkeep, you can minimize the risk of unexpected breakdowns, optimize crane performance, and prolong the operational lifespan of overhead crane systems in cashmere processing.

Conclusion

Overhead cranes have emerged as indispensable tools in the realm of cashmere processing, offering unparalleled efficiency, precision, and safety in material handling operations. From the delicate sorting and cleaning stages to the intricate spinning and weaving processes, overhead cranes play a pivotal role in ensuring the smooth flow of cashmere fibers through each stage of production. With their ability to provide precise handling, increased productivity, and enhanced safety benefits, overhead cranes have become integral components of modern cashmere processing facilities, empowering manufacturers to meet the growing demand for highquality cashmere products with confidence and proficiency.

In cashmere processing, continuous improvement in material handling practices is essential for maintaining competitiveness and sustainability. As consumer expectations evolve and market dynamics shift, manufacturers must remain agile and adaptable, constantly seeking innovative solutions to optimize efficiency, reduce waste, and enhance product quality. By embracing a culture of continuous improvement, cashmere processing facilities can identify opportunities for optimization, leverage technological advancements, and stay ahead of the curve in an everchanging industry landscape.

As we look to the future of cashmere processing, the adoption of overhead crane technology presents a compelling opportunity for manufacturers to elevate efficiency and sustainability in their operations. By embracing overhead crane technology, cashmere processing facilities can unlock new levels of productivity, safety, and operational excellence, while reducing environmental impact and enhancing overall sustainability. Now is the time for cashmere processing industries to harness the power of overhead cranes and embrace a brighter, more efficient future for cashmere production. Together, let's seize the opportunity to transform cashmere processing through innovation, collaboration, and a commitment to excellence.