Safe Operation of Gantry Crane: How to Use Gantry Crane Safely

How to operate gantry crane safely? What to check before gantry crane operation? What are common accidents of gantry crane operation? Check now.

The term "Gantry Cranes" refers to all cranes whose primary structural component is typically an overhead beam. Single girder gantry cranes and double girder gantry cranes are the two primary types of gantry cranes. Gantry and portal cranes are frequently employed in the engineering, industrial, and port industries for material handling. Operators must be knowledgeable and skilled to operate these cranes safely and to avoid accidents.

Preparation And Inspection Before Operation Of Gantry Crane

- Personnel who operated the gantry cranes has to be trained in crane operation.

- The crane driver and operator should be familiar with the crane's working principle and operating device, understand the function of its safety device and the correct operation method, and perform careful and timely maintenance.

- Check to see if there is a temporary power outage on site for maintenance.

- Examine the safety switches, transmission mechanisms, and brakes to ensure they are in good working order.

- Check to see if the fixing bolts on each part are loose, and if there are any scattered items on the gantry crane.

- As needed, apply grease to each lubrication point.

- Before powering on, all control handles must be turned to zero and all channel doors must be closed.

Gantry Crane Operation Safety

Gantry crane safety is critical for ensuring worker safety and efficiency, as well as extending the crane's service life. The following are the main important considerations for gantry crane operators:

1.Before using the gantry crane, check the brakes, hooks, wire ropes, and safety devices to ensure they are in good working order. Any unusual occurrences should be avoided.

2.When lifting a heavy object for the first time or when the load reaches the maximum weight, the operator should lower the heavy object after lifting 0.5 meters above the ground and inspect the brake for proper operation. Only after confirmation can the gantry crane operation be carried out.

3. When performing the following operations with the gantry crane, the operator must sound the alarm in accordance with the regulations:

- When the crane and trolley are driving, they are lifting and lowering heavy objects.

- When the gantry crane passes through areas where the line of sight is unclear, it should sound the alarm continuously.

- A warning should be given when the crane is approaching another crane within the span to avoid a collision.

- When a person is close to the lifting object, a warning must be issued promptly.

4. During crane operation, the crane driver must operate in accordance with the unified command signal.

5. If the power is suddenly cut off while the gantry crane is in operation, all crane controller handles should be set to the "zero" position. Check to see if the gantry crane movement is normal before reworking. You can proceed with the operation after confirming that everything is normal.

6. It is strictly forbidden to use the reverse brake to stop the gantry crane during normal operation. When changing the direction of the crane and trolley, the handle must be set to "zero" to completely stop the mechanism.

7. It is not permitted to hang two objects from the gantry crane with two hooks at the same time.

When the main and auxiliary hooks are switched, or when the heights of the two hooks are the same, the main and auxiliary hooks must be operated separately to avoid the two hooks colliding.

8. Adjusting the lifting mechanism brake while lifting is strictly prohibited.

9. If an abnormality is discovered while the gantry crane is in operation, it should be stopped immediately to investigate the cause and correct the problem as soon as possible.

10. After using the gantry crane, raise the crane hook to a specific height, park the crane and trolley at the specified location, set the controller handle to "zero," pull down the protective box switch handle, and turn off the power supply. The operator then performs daily maintenance.

It is hoped that safety operations on gantry cranes can be carried out in strict accordance with the above specifications. Only by operating the crane in accordance with the safety regulations can the operators' safety and working efficiency be ensured.

Common a ccidents needs to be avoid during crane operation

The majority of gantry crane accidents occur during the lifting process. The consequences of an accident can be severe, even fatal at times. Using the proper method and equipment will greatly reduce the possibility of accidents during lifting operations.

Overloading

Overloading

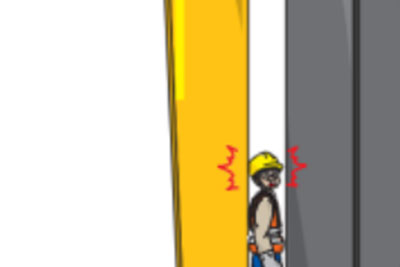

Caught in between a moving gantry crane and structure/ objects/ fixed obstruction

Caught in between load and lifting gear

Caught in between load and lifting gear Falling load to due to insecure rigging

Falling load to due to insecure rigging Hit by moving or swinging loads

Hit by moving or swinging loadsEnvironmental Condition s when operation outdoor conditions

Rain, thunderstorms, and strong winds can all have an impact on outdoor lifting operations of gantry cranes.

- Rain -All outdoor gantry cranes' equipment and sensitive components should have been designed with the proper Ingress Protection (IP) enclosure and shelters.

- Thunderstorms -Stop lifting operations immediately during thunderstorms.

- Strong Winds - Cranes should never be used when wind speeds exceed those recommended by the crane manufacturer.

- Stop all lifting operations and secure the gantry crane with a wind restraint device if strong winds occur.

OSHA Requirements and Regulations on Crane Safety

When efficiency is required for lifting and transporting heavy loads, overhead cranes—including gantry cranes—are crucial in many manufacturing, maintenance, and industrial work situations. Riggers, crane operators, and others who are close to overhead cranes need to be mindful of the particular dangers posed by these massive machines. The most frequent industrial overhead crane hazards are being caught in/between, being struck by/against, being overloaded, and falling materials.

Materials Handling and Storage - Overhead and Gantry Cranes is covered under OSHA General Industry Standard 1910 Subpart N.

Only trained and authorized individuals should be allowed to operate any overhead crane to ensure that everyone is kept safe while they are in use.

Employees who operate close to the overhead crane must receive training in workplace general safety awareness to make sure that all necessary safety measures are performed during the workday to keep everyone safe.

When overhead cranes are in operation, visitors shouldn't be permitted near them.

1910.179(b) of OSHA's General Industry Standard (8) A crane covered by this clause may only be operated by designated personnel.

At the start of each shift or before utilizing the crane for the first time each workday, conduct a fundamental crane inspection. Look for the following, at the very least:

- Examine the area near the crane for spills and other trip risks.

- Verify that guards are installed and functioning as planned.

- Check the wire rope for imperfections or damage.

- Check that the ropes are properly aligned on the drum.

- Check the block and hook for damage or cracks.

- Make sure the bumpers are damage-free.

- Check that the limit switches are functioning properly.

- Do not use the crane if any flaws or problems are discovered during any inspection; instead, report them right once.

- To document a more thorough routine inspection of all cranes, a crane inspection process should be created and written records should be kept.

Safety training of gantry crane and overhead crane operation

- Employees receive on-site instruction in crane operation and safety.

- The proper PPE, including as hard hats, safety glasses, work gloves, and hard-toe boots, must be worn by all crane operators, riggers, and personnel who perform their duties in an area where overhead cranes are in use.

- Common crane operating hand signals should be taught to the hoist operator and rigger, especially if there is ever an occasion where vocal communications are inaudible.

- Knowing the load rate is crucial for riggers and crane operators. The crane and hoist block should be marked with loads. Make sure the load does not exceed the lift's maximum load capacity before you begin.

- Riggers and hoist operators should not perform any additional actions while operating the crane which will distraction their attentions from the crane operation.

1910.179(n) of OSHA's General Industry Standard (1) size of the load The crane must not be loaded more than what is permitted.

- If you have not received training, do not attempt to maintain or repair any crane.

- Follow lockout/tagout procedures prior to doing any crane maintenance.

- Any overhead crane that has been designated "do not operate" or has been tagged out should not be used.

- If the controls are broken, never operate a crane.

- In the event that any load is suspended, controls shouldn't be left unmanaged. Lower the load initially if you must leave the controls for whatever reason.

1910.179(n)(3) of OSHA's General Industry Standard (x) While the load is suspended, the employer must make sure the operator doesn't abandon his place at the controls.

- Do not let any employees ride on any loads that a crane is lifting, or even on the crane hook itself.

- Never place loads on top of someone. Employ warning devices that can be heard or seen to give nearby personnel the opportunity to get out of the way of the weight.

- Never pass by a loaded crane while it is being lifted.

- Never should the load suddenly accelerate or decelerate while being lifted. Keep the cargo from moving abruptly or jerkily by controlling the crane slowly.

- Before lifting, be sure that all loose materials and parts have been removed from the load.

Make sure you attend the safety meeting if overhead or gantry cranes are utilized at your business, warehouse, or place of employment. Every employee who works in the area needs to be aware of the particular risks posed by industrial overhead cranes and the anticipated safe work practices.