Overhead Crane Cost : What You Pay For Overhead Bridge Crane ?

Almost every day, there may be multiple inquiries about the cost of bridge crane and crane installation. Whether the company wishes to replace an outdated or old overhead crane or explore purchasing a new one for corporate expansion, both require a consulting process first. To cut a long story short, crane cost is always one of the most important concerns for the majority of the corporations.

Many manufacturing companies have cranes designed and erected to their particular specifications. You will need a little more study and experience several procedures to buy a suitable bridge crane if you conduct study. Let us look at the aspects that influence the cost of bridge cranes.

Cost-influencing factors

Many businesses choose the incorrect bridge crane for their business expansion. To ensure that you are on the correct route, contact the leading bridge crane manufacturers, such as Yuantai Crane, for bidding purposes. You must prepare the following information for this purpose:

Type of bridge crane that you require

A bridge crane, on the other hand, is a complicated piece of machinery. One can select from a variety of options. The following considerations influence the type of crane required:

- The engineering required to design the crane to meet particular application

- The working environment or application conditions, including building or facility conditions

- The crane control required to operate the bridge crane

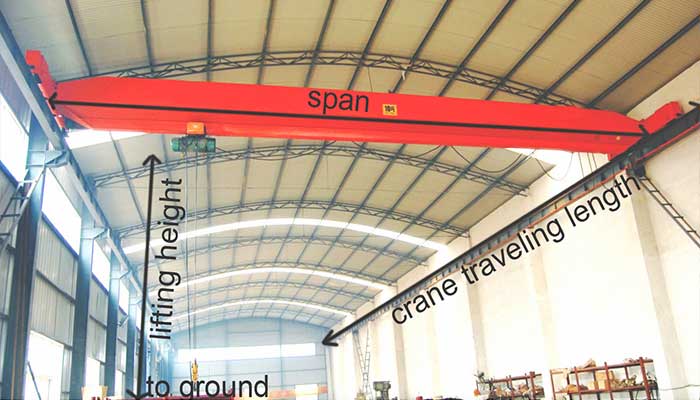

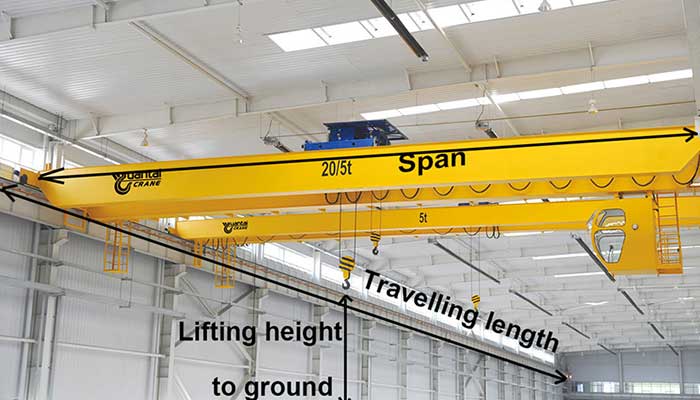

The bridge crane's span

The length of the span between the runway rails adds to the cost of bridge cranes. The larger span would increase the cost of the runway since it would require more material to construct the crane girders. A 40-meter wide bridge crane, for example, will cost more than twice as much as a 20-meter wide bridge crane.

Rated maximum load

A double girder design crane is one that requires a large span, large capacity, or service. Any crane that can carry a maximum load is deemed pricey.

Service classification / duty class of crane system

The crane manufacturers association of America categorized the service into six categories.

- Class A and Class B cranes will be the least expensive because they will be used infrequently.

- Class C cranes are required for unique and particular applications. They are mostly used sparingly. Overload cranes of class C have a capacity of 50%. These cranes are expected to operate at a rate of five to ten lifts per hour.

- Class D and Class E: These overload cranes are also known as process cranes. They are thought to be more robust. You can, however, make this work at 15 to 20 lifts every hour. These cranes are likely to have more specialized solutions for specific lifting purposes. As a result, the engineering and design costs rise, making it an expensive event.

- Class F cranes can handle everything and anything for the rest of their lives. They offer a terrible service. Class F cranes are expensive due to their engineering and design. Bridge cranes are more expensive because of the materials, labor, installation, and sourcing of heavy-duty components.

Delivery Period

The delivery lead time may be the most important aspect influencing your project's execution. In these cases, delivery time may be used as a selection or rejection factor. You must determine whether the bridge crane manufacturer's delivery time is reasonable. It will be determined by the manufacturer's available infrastructure and workload.

Working environment

Environmental variables such as chemicals, intense heat, dust, steam, and extreme moisture may necessitate a unique type of metal coating. It extends and protects the bridge crane's operational life.

The bridge cranes that must operate outside must be coated with a protective covering to avoid quotations. To eliminate the presence of moisture, dirt, or dust, the entire system must be waterproofed. Some cranes also needed waterproofing and weatherproofing to keep dust and moisture out.

In addition, if one is working in a hazardous operational area, they will need protective equipment or PPE. It would increase the overall cost of the quotation.

Runway Length

The length of the runway has a considerable impact on the cost of bridge cranes. A longer runway is required while making numerous picks. In order to move swiftly, a faster trolley and hoist are required.

Assume you wish to enhance the crane's targeted speed; you must operate it within an enclosed cab. It would cost more than the pendant controls.

The structural or construction requirements

If a bridge crane is built in the new construction site, the runway beam must be constructed during construction. In this situation, the runway structure would not be included in your quotation process. However, if the crane is to be installed in an existing facility, additional expenditures such as fabrication, installation, delivery, and design must be considered.

Hidden costs of bridge cranes system

Purchasing a bridge crane can be a significant investment for your organization. However, it will assist you in a variety of ways. For example, it will boost your productivity and stick by your side for a long period. Furthermore, their service life is pretty amazing. However, pricing is not the only factor to consider when purchasing a bridge crane. Other things will influence your purchase.

For example, if you buy a crane based solely on its inexpensive price without first researching its applications, you will be making a mistake. You must ensure that the lifting crane is appropriate for your application. Furthermore, you may be forced to pay certain unexpected fees. So, before purchasing your crane, you should be fully informed. We will go over everything so that you are not surprised by any hidden fees. It will help you save money.

Quotation and design process

The first step is to collaborate with a reputable crane manufacturer. The organization should be able to comprehend your specific requirements. Furthermore, it should comprehend your material and lifting issues. Finally, it will ensure that they are building a crane that is best suited to your needs.

Obtaining multiple bids from manufacturers is one of the best things you can do. It will give you a better idea of the true cost of purchasing a bridge crane. Furthermore, if a company learns that they are not the only one bidding, they will provide you with a superior service. Manufacturers will attempt to remain competitive.

You will receive more detailed and competitive quotes. They will go to great lengths to win your business. We'll get into the hidden fees now. Here are some elements to consider in order to grasp it. Here are the factors we're discussing.

Compare the bridge crane quotes

It is critical to compare the quotes. You must comprehend all of the specs as well as the other aspects of the quote. Comparing quotations can assist you in selecting the best of all. The best thing you can do is meet with all of the manufacturers and inform them about your idea. Once they understand your design, they will present you with a quote based on it. Keep in mind that purchasing the crane for the lowest price may cost you money in the long run. Maintenance and downtime, for example, could cost you money.

Design and Duty Cycle

You will be able to select the design based on the job cycle and classifications. During that period, you must select the safest and most cost-effective design. It must be ideal for your lifting needs. Furthermore, selecting the right duty cycle will ensure that all of your crane's components are up to standard and long-lasting. Before you buy, you should ask your manufacturer a few questions.

You must be truthful and transparent with them. The following are the questions:

- How frequently will you utilize the crane?

- The type of environment in which you will be working.

- How hard will your crane have to work?

It would be easier to create the best crane for you if you communicate these to your makers before purchasing the crane. If you under-specify the crane system, you may be able to make an initial low-cost investment. However, it may cost you more in the long term due to downtime and maintenance. As a result, it will be your hidden costs.

Inspections, transportation costs, and permits

When the manufacturer presents you with an estimate, there are a few items you should look through. The first question you should ask is whether they are offering you with a single quote that contains everything. Or are they providing you with a quote that includes itemized rates for various services? Ascertain the entire cost of the project.

When obtaining permissions, you should know whether the manufacturer or the installer will handle the paperwork. Furthermore, determine who will bear the associated fees and plan the surveys ahead of time. Otherwise, you will have to pay more money.

Material costs and expenses

It is an important component of the discussion. It is determined by the market value of steel. It is, after all, a volatile market. As a result, determining the exact cost of the bridge cranes is difficult. There is a chance that the quote will include a disclaimer. It will say that the anticipated cost of the material will be maintained for a set period of time. It is possible that it will alter after that time frame. You should therefore be aware of the disclaimer. We recommend that you get a consultation because it will help you make the best decision.

Some of the other common misunderstandings

Well, there may be some common misunderstandings between an bridge crane installer and the customer. Here, we will point out those misunderstandings so that you can avoid them to work together correctly.

- There is a possibility that you need in-house electrical work before load testing and installation.

- Make sure you are clear about who will do the electrification.

- Keep in mind that it is the work of a third party or in-house electrification. Make everyone clear about their work.

So, these are the hidden costs that you may have to come across after buying an bridge crane system.

Some of the other frequent misconceptions

There could be some frequent misconceptions between a bridge crane installer and the consumer. We will highlight those misunderstandings here so that you can prevent them when working together.

- There is a chance that you will require in-house electrical work prior to load testing and installation.

- Make sure you understand who will do the electrification.

- Remember that it is the work of a third party or internal electrification. Make everyone's responsibilities clear.

So, these are the hidden expenditures that you may encounter after purchasing a bridge crane system.

All in all, most crane manufacturers do not provide in-house structural repair certification services. As a result, you must consider the additional prices that your contractors supply throughout the consultation. When working with existing buildings, it is necessary to establish whether they can withstand the additional weight generated by the bridge crane installation. These factors generally always affect the cost of the bridge crane system.

Single Girder Overhead Crane For Sale

It is a light small lift equipment with the capacity of 1to 32 tons, which is the most commonly used small material handling equipment, suitable for most factories, warehouses, etc.

Lifting Capacity: 1~32t

Lifting Height: 6-30m

Span: 7.5~28.5m

Working Duty: A3, A4

Ambient Temperature: -20~40℃. Contact us to get your customized single girder crane cost.

| Overhead Crane | Span(m) | Lifting Height(m) | Power Supply(V) | Price(USD) |

| 1 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $2200~40000 |

| 2 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $2500~40800 |

| 3 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $2600~41000 |

| 5 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $3000~41500 |

| 10 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $4000~45000 |

| 16 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $5000~48000 |

| 20 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $6000~50000 |

| 25 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $8000~56000 |

The price of the above overhead bridge cranes will change with the market, without further notice, for reference only. If you need an accurate price in the near future, please contact us.

Double Girder Overhead Crane For Sale

The crane can lift loads from 5 to 63 ton, which is widely used in machinery fabrication, metallurgical plant auxiliary workshop, storage, stock ground, and power station, textile industry and food industry.

Lifting Capacity: 1~63t

Lifting Height: 6-30m

Span: 7.5~28.5m

Working Duty: A3, A4, A5

Ambient Temperature: -20~40℃. Contact us to get your cusotmized double girder crane cost.

| Overhead Crane | Span(m) | Lifting Height(m) | Power Supply(V) | Price(USD) |

| 1 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $4000-60000 |

| 2 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $4500-62000 |

| 3 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $5000-66000 |

| 5 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $5800-72000 |

| 10 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $6500-79000 |

| 16 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $7800-86000 |

| 20 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $8600-95000 |

| 25 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $9800-110000 |

The price of the above bridge cranes will change with the market, without further notice, for reference only. If you need an accurate price in the near future, please contact us.