Industrial Cranes for Sale in Poland: Overhead, Gantry, and Jib Crane Solutions

Crane Types Available for Sale

Overhead Cranes

Overhead cranes are widely used in Polish factories, steel workshops, logistics centers, and power equipment plants. Whether you're building a new facility or upgrading an old system, choosing the right configuration matters. Yuantai offers various designs suited for different lifting needs and ceiling structures.

Common Configurations:

- Single Girder Cranes – Suitable for light to medium loads. These are easier to install, economical, and ideal for spans under 25 meters.

- Double Girder Cranes – Better suited for heavy-duty applications and frequent use. They allow higher hook height and longer spans.

Mounting Types:

- Top Running Overhead Cranes – Installed on rails above the runway beams. A good option when headroom is available and heavier loads are expected.

- Underslung Cranes (Suspension Cranes) – Installed under the runway beams. These are often used when the workshop has limited headroom or light roof structures.

Hoist Options:

- Electric Wire Rope Hoists – Strong and stable, used for loads above 3 tons or when smooth lifting and precise control are required.

- Electric Chain Hoists – Compact and affordable, used for lighter lifting tasks, typically up to 3 tons.

Special Variants:

- Explosion-Proof Overhead Cranes – Available with flame-proof motors, enclosures, and control systems. These are designed for use in hazardous environments such as chemical plants, gas facilities, and coal preparation workshops.

Practical Use Cases in Poland:

- Handling steel coils and plates in Katowice steel plants

- Lifting turbine components in power plants near Kraków

- Assembly work in automotive workshops in Gliwice

Optional Features to Consider:

- Anti-sway control for precise positioning

- Frequency inverters for smooth speed control

- Wireless remote control or cabin operation

- Limit switches and overload protection for safety

If you're unsure about the best type for your workshop layout or weight handling, our engineers can guide you through the options based on your ceiling height, load type, and usage frequency.

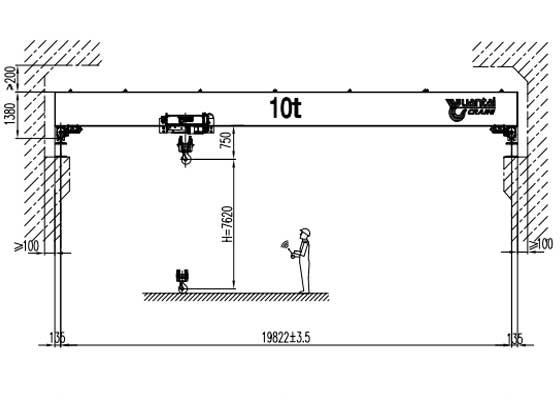

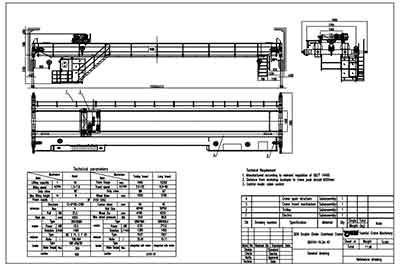

Overhead Cranes – 5 to 50 Ton Range

Overhead cranes are a staple in Polish production halls and steel plants. Whether you’re handling steel plates, heavy equipment, or assembly components, these lifting systems offer a strong mix of reach, precision, and lifting power.

Popular Capacities:

- 5 ton – Used in light manufacturing and repair shops

- 10 ton – Ideal for general-purpose lifting in most midsize factories

- 20 ton – Common in steel processing and fabrication plants

- 50 ton – Heavy-duty use, often paired with double trolleys or twin hoists

Key Features:

- Suitable for long spans (20m and above)

- Dual hoist options for tandem lifting or better load distribution

- Compatible with workshop cranes in automotive or mechanical assembly lines

Gantry Cranes

Gantry cranes are a go-to solution for many Polish industries where overhead support structures aren’t practical—or simply don’t exist. They offer the flexibility of being installed outdoors or in open production areas and can even be moved to new sites if needed. Whether you're managing a steel storage yard in Katowice or a precast concrete plant near Wrocław, there’s a gantry crane that fits.

Gantry Cranes – 10 to 32 Ton Range

Polish buyers working in outdoor yards or logistics hubs often choose gantry cranes for their flexibility and independence from roof structures. These cranes are built to handle rough weather and heavy materials, especially in steel or concrete-related industries.

Popular Capacities:

- 10 ton – Great for basic steel yard or construction site lifting

- 20 ton – Used for beam handling and outdoor material storage

- 32 ton – Heavy-duty lifting for precast or infrastructure projects

Key Features:

- Ideal for container loading/unloading in inland depots

- Works well in open fabrication yards with no indoor cranes

- Can be rail-mounted or rubber-tired for different mobility needs

Jib Cranes

Jib cranes are compact, efficient, and built to make everyday lifting tasks easier—especially in tight or fixed work areas. They’re commonly seen in Polish workshops, machine assembly lines, maintenance stations, and even small loading docks. When you need to lift a load quickly within a limited radius, without involving an overhead or gantry crane, a jib crane is often the best tool for the job.

They don’t require major structural work and can be installed either on the floor or mounted to an existing column or wall. And for many buyers, that simplicity is a major advantage.

Jib Crane Mounting Options

Wall-Mounted Jib Cranes

These are fixed directly to structural walls or building columns. No floor space is occupied, which is great in small or cluttered workshops.

- Common in production lines, machine tool stations

- Swing angles typically up to 180°

- Saves space and reduces installation time

Floor-Mounted (Pillar-Mounted) Jib Cranes

Installed directly into the concrete floor using anchor bolts and base plates. These allow greater rotation and wider working areas.

- Full 360° rotation available

- Ideal for standalone workstations or loading zones

- Suitable for indoor and covered outdoor use

Lifting Capacity and Rotation Options

Lifting Capacities:

Standard jib cranes range from 0.25 ton to 5 tons. Most common purchases in Poland fall between 1 to 3 tons, especially in light manufacturing and parts assembly.

Rotation Methods:

- Manual Rotation – Simple, reliable, and cost-effective. Best for lighter loads or occasional use.

- Electric Rotation – Powered slewing system for smoother, easier operation. Recommended for frequent or heavier handling, especially in busy work environments.

Jib arms can also be configured with manual or electric hoists—chain hoists are often preferred for their compact size and low maintenance.

Typical Applications in Poland

Jib cranes are found across many industrial sectors, especially in areas where materials or components are repeatedly lifted in the same spot:

- Machinery Assembly Lines in Poznań – For lifting motors, panels, or gearboxes at individual workbenches

- Vehicle Repair Bays in Tychy and Lublin – Used to lift engines, transmissions, or parts during maintenance

- Small Foundries or Welding Shops in Rzeszów – Assist in loading raw materials into machines or molds

- Packaging and Loading Zones in Warsaw – Support final product handling before truck loading

- Universities and Technical Labs – Used in training rooms or labs for safe material testing setups

Key Considerations for Buyers

- Confirm structural support for wall-mount types

- For floor-mount types, check concrete thickness (typically at least 200–300 mm required)

- Decide between fixed arm length or adjustable cantilever

- Select chain or wire rope hoists depending on lifting height and frequency

- Factor in operating environment—indoor, outdoor, temperature, or dust exposure

Jib Cranes – 0.5 to 3 Ton Range

If you’re working in a small shop or have a tight corner in a production line, jib cranes are often the most efficient solution. They offer local lifting support where full crane systems aren’t necessary.

Popular Capacities:

- 0.5 ton – For lifting light parts or tools in repair workshops

- 1 ton – Common in packaging stations or maintenance bays

- 2 ton / 3 ton – Suitable for assembly areas needing frequent lifting

Key Features:

- Quick installation with minimal structural work

- Space-saving design—great for wall or floor mounting

- Simple manual or electric rotation to cover specific work zones

Typical Applications in Poland

Poland’s industrial landscape is diverse, ranging from heavy steel production to precision automotive manufacturing. Different crane types and capacities fit naturally into specific sectors and tasks. Here’s a breakdown of where cranes are commonly used across Polish industries and what kinds of lifting jobs they handle.

Steel and Foundry Plants

Handling raw materials and heavy steel products is at the core of steel mills and foundries in Poland. Cranes in this sector must be tough and reliable to move hot metal safely and efficiently.

- Billet and slab handling: Overhead cranes equipped with electromagnetic or clamp attachments lift and move steel billets and slabs within processing areas.

- Hot metal transportation: Specially designed overhead cranes with heat-resistant features transport molten or red-hot metal between furnaces and casting machines.

- Used mainly in industrial regions like Upper Silesia and Katowice, where steel and foundry plants dominate.

Automotive Assembly Lines

Poland has a strong automotive manufacturing base, especially around cities like Tychy, Poznań, and Gliwice. Cranes here focus on precision and repeatability to keep production flowing smoothly.

- Precision hoisting: Electric wire rope hoists provide controlled lifts for car body parts, engines, and chassis components.

- Workstation support: Jib cranes and light overhead cranes assist workers by lifting parts within tight assembly areas.

- These cranes are designed for frequent, repetitive lifts with minimal sway and smooth speed control.

Construction Sites

Construction projects throughout Poland—from Warsaw's expanding skyline to regional infrastructure upgrades—need cranes that are rugged and flexible.

- Lifting steel bars and rebar bundles: Gantry cranes and overhead cranes move reinforcing steel safely around building sites.

- Precast concrete handling: Gantry cranes with high capacities lift and position heavy precast beams and panels.

- Structural frames: Steel framework assembly is supported by mobile gantry cranes or jib cranes at ground level.

- These cranes often operate outdoors and must withstand varying weather conditions.

Rail Yards and Ports

With Poland's growing logistics sector, rail yards and inland ports demand cranes for efficient cargo movement.

- Container handling: Rail-mounted gantry cranes (RMG) unload and stack containers with precision.

- Intermodal transfer: Rubber-tired gantry cranes (RTG) move containers between trucks and trains.

- These cranes are essential in major logistics hubs like the Port of Gdańsk and rail terminals around Poznań.

Warehouses and Logistics Hubs

Light and medium-duty cranes support material flow in warehouses and distribution centers across Poland.

- Overhead cranes and jib cranes are common for lifting pallets, crates, and equipment.

- Efficient material handling shortens loading times and improves workplace safety.

- Popular in fulfillment centers near Warsaw, Łódź, and Wrocław.

Energy & Utilities

Power plants, turbine manufacturers, and maintenance teams use cranes tailored for heavy and awkward loads.

- Turbine component maintenance: Overhead cranes lift and maneuver turbine rotors, blades, and casings.

- Part installation: Precision cranes help install large equipment pieces during power plant construction or refurbishment.

- Used in facilities around Kraków, Szczecin, and industrial zones near Łódź.

Workshops and Maintenance Areas

Many Polish factories and repair shops rely on smaller cranes to support daily operations.

- Jib cranes and portable gantry cranes help rotate heavy parts and lift components during repairs.

- These cranes increase efficiency by reducing manual lifting and improving safety.

- Found in machine shops, vehicle maintenance bays, and technical training centers.

Key Industrial Sectors Served in Poland

Poland’s industrial landscape is both broad and specialized, with different regions supporting distinct sectors that rely heavily on reliable crane solutions. Understanding where and how cranes are used helps us tailor the best lifting equipment to meet the unique needs of each industry.

- Steel and Metallurgy : Poland’s steel industry is one of its economic backbones. Plants in these areas handle large volumes of heavy steel products daily. Overhead cranes and gantry cranes are essential for moving billets, slabs, and molten metal safely and efficiently. Heavy-duty cranes with special features like heat resistance and electromagnetic attachments are common here. Regions: Upper Silesia, Katowice, Częstochowa

- Mining and Heavy Equipment : Mining operations and heavy equipment manufacturing require cranes that handle large, bulky loads often in tough environmental conditions. Gantry cranes and overhead cranes with rugged designs help lift mining components, heavy machinery, and materials used in open-pit and underground mining operations. Regions: Lubin, Bełchatów, Wałbrzych

- Shipbuilding and Port Handling : Coastal cities host shipyards and ports that rely on cranes for moving containers, ship components, and bulk cargo. Rail-mounted and rubber-tired gantry cranes, along with heavy-duty jib cranes, are key players in these sectors for loading, unloading, and assembly tasks.Regions: Gdańsk, Szczecin, Świnoujście

- Automotive Manufacturing : Poland is a growing hub for automotive assembly and parts manufacturing. Precision overhead cranes and jib cranes help maintain smooth workflow in assembly lines and workshops. Frequent lifting of engine blocks, chassis parts, and tools calls for cranes with fine control and high reliability.Regions: Poznań, Gliwice, Tychy, Warsaw outskirts

- Renewable Energy : The renewable energy sector is expanding fast, with cranes used to install large components like wind turbine blades and solar modules. Mobile gantry cranes and lightweight jib cranes provide flexibility in both remote and industrial settings, ensuring safe handling of delicate parts.Regions: Poznań, Gliwice, Tychy, Warsaw outskirts

- Logistics and Warehousing : Warehouses and distribution centers depend on cranes for fast and safe handling of goods. Overhead cranes and jib cranes are widely used to improve efficiency in packing, loading, and storage operations. Regions: Łódź, Warsaw outskirts, Wrocław, Kraków

Notable Project Locations in Poland

| Location |

Industry Focus |

Example Crane Usage |

| Katowice |

Steel Production & Processing |

20–50 ton overhead cranes in mill buildings |

| Gdańsk & Gdynia |

Shipbuilding & Maritime Logistics |

Gantry cranes for hull assembly and cargo handling |

| Warsaw |

Logistics & Automation |

Jib cranes and modular overhead cranes |

| Tychy & Poznań |

Automotive Manufacturing |

Workshop cranes with ergonomic hoists |

| Lublin |

Mining Equipment Support |

Request a Quotation or Consultation

Are you searching for an efficient lifting solution tailored to your needs in Poland? Whether you’re upgrading your workshop crane or planning a large-scale project, we’re here to help every step of the way.

Our experienced team offers comprehensive support to make sure you get exactly the right crane for your application—without any guesswork.

How We Can Help

- Technical Support and Layout Proposals

We analyze your workspace, load requirements, and operational flow to design crane layouts that maximize safety and productivity. Whether it’s a complex overhead crane system or a simple jib crane installation, we provide clear drawings and expert advice.

- Price Estimates for Different Crane Types and Capacities

Get accurate pricing based on your specific needs. We offer competitive quotes for overhead cranes, gantry cranes, jib cranes, and customized solutions, factoring in all necessary accessories and certifications.

- Lead Time and Shipping to Polish Project Sites

We coordinate fast and reliable shipping from our manufacturing facilities to your location anywhere in Poland. We also provide realistic delivery schedules so you can plan installation without delays.

Just reach out with your project details or questions. Our team will respond promptly with tailored recommendations and a no-obligation quotation.