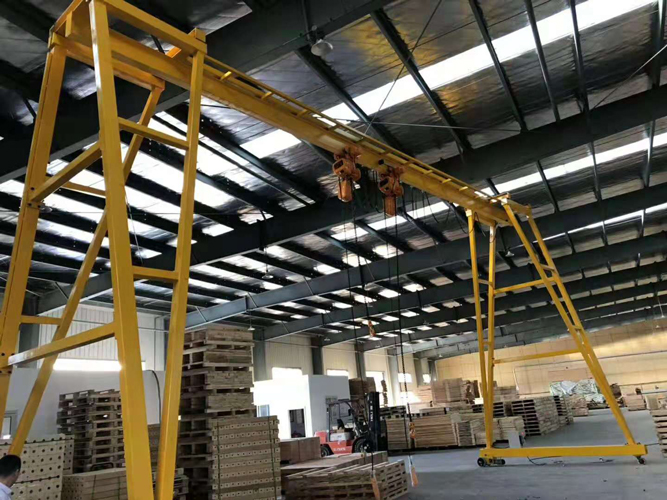

5 Ton Mobile Gantry Crane for Trucks Loading & Unloading, Good PRICE

5 Ton Moble Gantry Crane for Trucks Loading & Unloading, Good PRICE. 5 ton mobile gantry cranes for loading/unloading heavy agricultural equipment, machinery, and harvested crops onto trucks and transport vehicles. Check!Crop Handling and Processing Plant with 5 Ton Mobile Gantry Cranes in Brazil

Brazil is a global powerhouse in the agricultural industry, known for its vast and diverse crop production. As one of the world's leading producers and exporters of agricultural commodities, Brazil's success in this sector is largely dependent on the efficiency and effectiveness of its crop handling and processing operations.

Effective crop handling and processing are crucial for several reasons:

- Minimizing Crop Losses: Proper handling and storage of harvested crops can significantly reduce waste and losses, ensuring that a greater proportion of the yield reaches the market and consumers.

- Maintaining Quality and Freshness: Careful handling and processing techniques help preserve the quality, flavor, and nutritional value of agricultural products, making them more appealing to buyers and consumers.

- Streamlining Supply Chains: Efficient crop handling and processing contribute to the smooth flow of agricultural products through the supply chain, from the farm to the enduser, reducing delays and bottlenecks.

- Enhancing Competitiveness: In the global agricultural market, countries that excel in crop handling and processing can gain a competitive advantage, securing more lucrative trade deals and increasing their market share.

Against this backdrop of the importance of efficient crop handling and processing, the introduction of 5 ton mobile gantry cranes has emerged as a gamechanging solution for the agricultural sector in Brazil. These versatile and powerful cranes are transforming the way farmers, cooperatives, and processing facilities approach the critical tasks of moving, lifting, and positioning heavy agricultural equipment, machinery, and harvested crops.

The mobility and adaptability of these 5 ton gantry cranes allow them to be deployed across a wide range of agricultural settings, from largescale farms to processing facilities, enabling seamless integration with existing infrastructure and workflows. By leveraging the capabilities of these mobile cranes, Brazilian agricultural businesses can unlock new levels of efficiency, productivity, and crop protection, positioning themselves for sustained growth and success in the global market.

Utilizing 5 Ton Mobile Gantry Cranes for Truck Loading and Unloading

Advantages of Using 5Ton Mobile Gantry Cranes for Loading and Unloading

Improved Speed and Precision in Handling Heavy Agricultural Equipment and Machinery

The sheer power and versatility of 5 ton mobile gantry cranes make them an invaluable asset for efficiently handling heavy agricultural equipment and machinery. Whether it's moving large tractors, harvesters, or other specialized farm equipment, these cranes can lift and transport these bulky items with ease and precision, dramatically reducing the time and labor required for loading and unloading operations.

Seamless Transfer of Harvested Crops (Grains, Fruits, Vegetables) to Trucks and Transport Vehicles

In addition to managing heavy machinery, 5 ton mobile gantry cranes excel at handling harvested crops, including grains, fruits, and vegetables. Their powerful lifting capacity and precise control allow for the seamless transfer of these sensitive agricultural products from storage or processing facilities directly onto trucks and transport vehicles, ensuring a smooth and efficient journey to market.

Reduced Risk of Crop Damage During Loading and Unloading

One of the key advantages of using 5 ton mobile gantry cranes for crop handling is the significantly reduced risk of damage to the harvested produce. The delicate nature of many agricultural crops, such as fragile fruits and vegetables, requires careful handling to maintain their quality and marketability. The controlled and precise movements of these cranes minimize the potential for bruising, crushing, or other forms of damage during the critical loading and unloading stages.

By leveraging the speed, precision, and damageminimizing capabilities of 5 ton mobile gantry cranes, Brazilian agricultural businesses can optimize their loading and unloading operations, ensuring that their valuable crops and equipment are handled with the utmost care and efficiency.

Case Studies and Examples of Successful Implementation

Improved Efficiency in Loading/Unloading Operations on Brazilian Farms

The adoption of 5 ton mobile gantry cranes has transformed the loading and unloading processes on many Brazilian farms, leading to significant improvements in efficiency and productivity. One notable example is the experience of Fazenda Santa Maria, a largescale soybean and corn producer in the heart of Brazil's agricultural heartland.

Prior to implementing the 5 ton mobile gantry crane solution, the team at Fazenda Santa Maria faced numerous challenges in moving their heavy harvesting equipment and transferring their crops onto transport vehicles. The process was slow, laborintensive, and prone to delays, hampering their overall operational efficiency.

However, after investing in a fleet of 5 ton mobile gantry cranes, the farm saw a dramatic transformation. The cranes' ability to swiftly and precisely handle the massive combines, tractors, and trailers used in their operations streamlined the loading and unloading process, reducing the time and manpower required. Additionally, the cranes' gentle yet powerful handling of the harvested grains, minimized the risk of crop damage, ensuring that a greater proportion of the yield reached the market in pristine condition.

Increased Productivity and Reduced Labor Requirements

The introduction of 5 ton mobile gantry cranes has not only improved efficiency but has also significantly increased productivity and reduced labor requirements on Brazilian farms and in agricultural facilities. At the Cooperativa Agrícola de Cotia, a large agricultural cooperative, the deployment of these cranes has transformed the way they handle heavy machinery and process their diverse crop yields.

Prior to the implementation of the mobile gantry crane solution, the cooperative's crop handling and processing operations were highly laborintensive, relying on teams of workers to manually load and unload equipment and transport crops. However, with the introduction of the 5 ton cranes, the cooperative has been able to streamline these processes, reducing the number of workers required while simultaneously increasing the speed and volume of their handling capabilities.

The cooperative's management has reported a significant boost in overall productivity, as the cranes' ability to work tirelessly without breaks has allowed them to maintain a constant flow of operations, even during peak harvest seasons. This increased efficiency has not only improved the cooperative's bottom line but has also enhanced their competitiveness in the local and regional agricultural markets.

These case studies and examples highlight the transformative impact that 5 ton mobile gantry cranes can have on crop handling and processing operations in Brazil's agricultural sector, paving the way for enhanced productivity, reduced labor requirements, and improved overall efficiency.

Integrating Mobile Gantry Cranes with Crop Processing and Distribution Systems

Combining 5Ton Mobile Gantry Cranes with Conveyor Systems

Streamlining the Movement of Crops from Harvesting to Processing Facilities

The integration of 5 ton mobile gantry cranes with conveyor systems has revolutionized the way Brazilian agricultural businesses manage the movement of crops from the field to processing facilities. These powerful cranes can seamlessly interface with existing conveyor belts, allowing for a seamless and efficient flow of harvested crops.

By positioning the mobile gantry cranes at strategic points along the conveyor system, farmers and processors can ensure a continuous and uninterrupted transfer of their valuable yields. The cranes' ability to lift and position crops with precision and speed ensures that the products move through the system without delays or bottlenecks, optimizing the overall workflow.

Enhancing the Efficiency of Crop Handling and Distribution

The integration of mobile gantry cranes with conveyor systems has also resulted in significant enhancements to the efficiency of crop handling and distribution operations. With the ability to rapidly and accurately transfer crops from one point to another, these integrated systems have reduced the manual labor required and minimized the risk of product damage during handling.

Furthermore, the improved efficiency in crop movement has allowed Brazilian agricultural businesses to streamline their distribution networks, ensuring that their products reach the market in a timely manner. This, in turn, has contributed to a more reliable and consistent supply of agricultural commodities, benefiting both producers and consumers.

By seamlessly integrating 5 ton mobile gantry cranes with their existing conveyor systems, Brazilian farmers and processors have been able to elevate their crop handling and distribution capabilities, driving greater productivity, reducing operational costs, and strengthening their competitive position in the global agricultural marketplace.

Integrating Mobile Gantry Cranes with Storage Facilities

Optimizing the Placement and Movement of Crops in Storage

The integration of 5 ton mobile gantry cranes with storage facilities has unlocked unprecedented levels of efficiency and precision in the management of harvested crops. These versatile cranes have the ability to precisely position and rearrange stored commodities, ensuring optimal utilization of available space and enhancing the overall organization of the storage operations.

By leveraging the cranes' lifting capacity and precise control, agricultural businesses in Brazil can strategically place and stack their harvested crops, such as grains, fruits, and vegetables, in a manner that maximizes the storage capacity. This optimized storage layout not only increases the volume of products that can be accommodated but also facilitates efficient retrieval and distribution when the time comes to move the crops to the next stage of the supply chain.

Improving the Overall Workflow and Reducing Bottlenecks

Beyond the optimization of storage placement, the integration of mobile gantry cranes with storage facilities has also resulted in significant improvements in the overall workflow and the reduction of bottlenecks. The seamless movement of crops facilitated by these cranes ensures a smooth transition from harvesting to storage, and from storage to distribution, minimizing delays and maximizing the throughput of the entire system.

By eliminating manual handling and streamlining the movement of crops within the storage facilities, Brazilian agricultural businesses have been able to reduce the time and labor required for these critical operations. This, in turn, has translated into faster turnaround times, improved responsiveness to market demands, and a more resilient supply chain that is better equipped to handle fluctuations in production and distribution.

The integration of 5 ton mobile gantry cranes with storage facilities has emerged as a gamechanging strategy for Brazilian agricultural enterprises, enabling them to optimize their crop handling and storage processes, increase operational efficiency, and strengthen their competitive edge in the global market.

Optimizing Crane Placement and Movement

Importance of Strategic Crane Placement

Minimizing Crop Damage During Handling

The strategic placement of 5 ton mobile gantry cranes within agricultural operations is crucial for minimizing the risk of crop damage during handling. These powerful machines, when positioned optimally, can ensure that harvested crops are moved with the utmost care and precision, reducing the potential for bruising, crushing, or any other form of physical damage that can compromise the quality and marketability of the produce.

By carefully analyzing the layout of their facilities and the flow of operations, Brazilian farmers and processors can identify the ideal locations for their mobile gantry cranes. This strategic positioning allows the cranes to seamlessly integrate with existing infrastructure, such as storage silos, processing lines, and transportation access points, enabling a smooth and controlled transfer of crops throughout the handling process.

Improving Overall Handling Efficiency

In addition to minimizing crop damage, the strategic placement of 5 ton mobile gantry cranes also plays a crucial role in enhancing the overall efficiency of agricultural handling operations. By positioning the cranes at key junctures within the workflow, farmers and processors can streamline the movement of crops, equipment, and machinery, reducing unnecessary movements and eliminating potential bottlenecks.

This optimized crane placement, combined with the cranes' ability to work in coordination with other handling equipment, such as conveyors and forklifts, results in a more streamlined and productive handling process. As a result, Brazilian agricultural businesses can achieve higher throughput, reduced labor requirements, and a more efficient utilization of their resources, ultimately strengthening their competitiveness in the global market.

By prioritizing the strategic placement of their 5 ton mobile gantry cranes, Brazilian agricultural enterprises can maximize the benefits of these versatile machines, ensuring the protection of their valuable crops while also enhancing the overall efficiency and productivity of their handling operations.

Techniques for Optimizing Crane Movement

Analyzing the Layout and Flow of Operations

To unlock the full potential of their 5 ton mobile gantry cranes, Brazilian agricultural businesses must carefully analyze the layout and flow of their operations. This comprehensive assessment involves mapping out the physical configuration of their facilities, including the placement of storage silos, processing lines, and transportation access points, as well as the typical movement patterns of crops, equipment, and personnel.

By understanding the existing layout and workflow, agricultural enterprises can identify strategic positions for their mobile gantry cranes that will optimize the overall handling process. This analysis may reveal opportunities to streamline the movement of crops, minimize unnecessary handling steps, and eliminate potential bottlenecks, all of which contribute to enhancing the efficiency and productivity of the operation.

Developing Efficient Crane Routing and Scheduling

Complementing the strategic placement of mobile gantry cranes is the development of efficient crane routing and scheduling protocols. This involves creating a comprehensive plan that outlines the optimal movement and utilization of the cranes throughout the various stages of the agricultural workflow.

By carefully mapping out the specific tasks and responsibilities of each crane, agricultural businesses can ensure that their handling operations are executed in a coordinated and seamless manner. This includes establishing efficient crane movement patterns, minimizing idle time, and synchronizing the cranes' activities with other handling equipment and personnel.

Furthermore, the implementation of advanced scheduling algorithms and realtime monitoring systems can further enhance the optimization of crane movement. These tools can help agricultural enterprises adapt to changing conditions, respond to fluctuations in production, and make informed decisions to maintain the smooth and efficient flow of their handling operations.

By analyzing the layout and flow of their operations and developing efficient crane routing and scheduling protocols, Brazilian agricultural businesses can unlock the full potential of their 5 ton mobile gantry cranes, driving improved productivity, reduced operational costs, and a stronger competitive position in the global market.

Conclusion: Get Your Custom Mobile Gantry Cranes

The introduction of 5 ton mobile gantry cranes has revolutionized the way Brazilian agricultural enterprises handle and process their valuable crops. These versatile and powerful machines have delivered a range of tangible benefits that have significantly enhanced the efficiency, productivity, and competitiveness of the sector.

Key benefits include:

Improved speed and precision in handling heavy agricultural equipment and machinery, as well as harvested crops

Seamless integration with conveyor systems and storage facilities to streamline crop processing and distribution

Reduced risk of crop damage during loading, unloading, and storage operations

Increased overall handling efficiency through strategic crane placement and optimized movement

Reduced labor requirements and enhanced productivity across various agricultural operations

As the Brazilian agricultural sector continues to thrive and expand, the demand for efficient and innovative handling solutions is expected to grow. The proven success of 5 ton mobile gantry cranes in improving crop handling and processing operations positions them as a crucial asset for the future of the industry.

As the agricultural industry continues to evolve, the 5 ton mobile gantry crane is poised to play a pivotal role in shaping the future of crop handling and processing in Brazil, solidifying the country's position as a global agricultural powerhouse.