Yuantai BCD Explosion-Proof Hoist : Safe, Reliable, Certified

Yuantai BCD Explosion-Proof Electric Hoists (Exd IIBT4 / CT4) – Safe, Strong, Certified

Executive Summary: Safe Lifting in Hazardous Areas with Yuantai BCD Explosion-Proof Hoists

Yuantai’s BCD explosion-proof electric hoists are built for industries where gas or dust could ignite—like oil, gas, paint, or chemical plants. These hoists are strong, spark-proof, and certified to handle dangerous zones safely. If you're looking for reliable lifting equipment that meets safety standards, Yuantai gives you certified quality, stable performance, and trusted support.

Why Explosion-Proof Matters

Working in hazardous environments isn't just risky—it's regulated. If you're lifting loads in areas with flammable gases, vapors, or dust, you need more than a standard hoist. You need an explosion-proof one. Here's why:

Understanding Hazardous Zones

- Zone 1: An area where explosive gas is likely to occur during regular operations. Common in oil refineries, gas stations, and chemical plants.

- Zone 2: Explosive gas may occur occasionally or for a short time. Found in paint shops, storage tanks, or maintenance pits.

Gas Groups:

- IIA – Less flammable gases (propane, acetone)

- IIB – Medium risk gases (ethylene, town gas)

- IIC – Highest risk (hydrogen, acetylene, carbon disulfide)

Note: Yuantai hoists cover Exd IIBT4 and Exd IICT4—suitable for most explosive environments.

What Causes Ignition During Lifting?

- Electrical sparks from motors or wiring

- Hot surfaces on motor casings or gearboxes

- Friction sparks from hooks, brakes, or running wheels

- Static electricity buildup on moving components

Even one spark in the wrong place can lead to an explosion. That’s why every component in an explosion-proof hoist—motor, wiring, brakes, even the hook—is designed to prevent ignition.

The Cost of Using a Non-Certified Hoist

Choosing the wrong hoist doesn’t just cost money—it can cost lives. Consider:

- Downtime: A single safety violation can shut down operations for days or weeks.

- Accidents: Fires or explosions can lead to injuries, equipment loss, or worse.

- Fines & Legal Risks: Regulatory bodies like ATEX, IECEx, or local safety agencies enforce strict rules. Violations can bring hefty fines or criminal charges.

Using a certified explosion-proof hoist like Yuantai’s BCD model isn’t just smart—it’s essential. It keeps your workers safe, your equipment running, and your business in compliance.

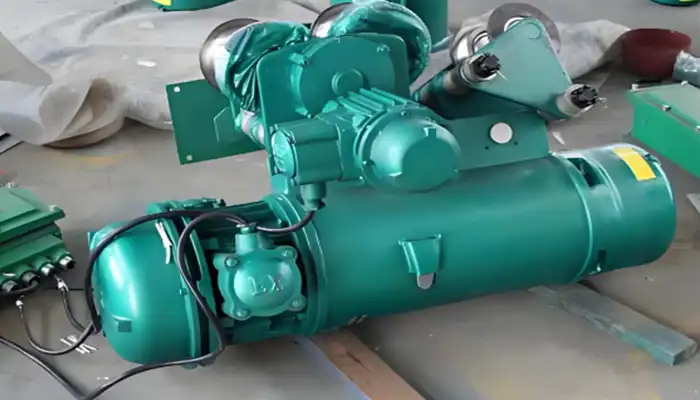

Meet the BCD Series of Wire Rope Explosion Proof Hoist

The Yuantai BCD Explosion-Proof Electric Hoist Series is designed for safe lifting in hazardous environments, without sacrificing performance. Whether you're working in a Zone 1 refinery or a Zone 2 paint shop, there’s a BCD model to match your needs.

BCD explosion proof wire rope hoist for sale, affordable price

Quick Snapshot: Key Specs at a Glance

| Feature | Specification |

|---|---|

| Lifting Capacity | 0.25 ton to 63 tons |

| Lifting Height | 1 meter to 100 meters |

| Speed Options | Single speed / Double speed |

| Working Duty | M3 (Light to moderate use) |

| Explosion-Proof Grade | Exd IIBT4 / Exd IICT4 |

| Power Supply | 3-phase, 380V, 50Hz (customizable) |

Need high lift? Need slow speed for precise control? The BCD Series handles both.

Stationary vs. Trolley Type – What’s the Difference?

Yuantai offers two installation options to match your site layout:

Stationary Type

- Mounted to a fixed beam or support structure

- Ideal for vertical lifting in confined spaces

- Great for low-movement zones like test labs or storage bays

Trolley Type (Mobile Version)

- Moves horizontally on an I-beam or crane runway

- Works in both straight lines and curves

- Perfect for production lines, tank farms, or maintenance areas

Trolley hoists are the go-to for workshops and crane bridges. If you need to lift and shift heavy loads across a space, this is your best bet.

Yuantai’s BCD Series isn't just another hoist. It’s a customizable, explosion-proof lifting solution that adapts to your job site and safety requirements. Whether you need precision placement or high-speed lifting, this series is built to work—safely and reliably.

Certified Safety: What Makes Yuantai BCD Hoists Truly Explosion-Proof

When lifting in flammable gas zones, safety is not optional. Yuantai BCD explosion-proof electric hoists are tested, certified, and built for hazardous environments—rated Exd IIBT4 and Exd IICT4. Here’s what that means and why it matters to your operation.

What Is "Exd"?

"Exd" stands for flameproof enclosure.

It’s a protective method where any internal spark or flame is contained inside the hoist’s body. This prevents outside gases from igniting, even if something goes wrong inside the unit.

Key points:

- Designed to contain internal explosions.

- Built to resist pressure and heat without damage.

- Prevents flames or sparks from reaching the surrounding air.

In short, it protects the inside from the outside—and the outside from the inside.

Gas Groups: IIB vs. IIC

Not all gases are equally dangerous. The hoist’s rating tells you what types of gases it’s safe to use around.

| Gas Group | Typical Gases | Safety Level |

|---|---|---|

| IIB | Ethylene, coke oven gas | Medium to high risk |

| IIC | Hydrogen, acetylene | Very high risk |

A hoist rated for IIC can also be used in IIB environments. Choosing IIC-rated equipment gives you more coverage and flexibility.

Temperature Class: T4 in Plain Language

Some flammable gases don’t need a spark—they can ignite from surface heat alone. That’s why temperature class matters.

T4 means the external surface temperature of the hoist will not exceed 135°C, even during long use. This keeps it below the ignition point of most industrial gases.

Quick reference for temperature classes:

- T1: ≤ 450°C

- T2: ≤ 300°C

- T3: ≤ 200°C

- T4: ≤ 135°C

Yuantai BCD hoists are T4-rated to safely handle the majority of hazardous environments.

Certified by Jiamusi Testing Institute

Yuantai’s BCD hoists are independently tested and certified by the Jiamusi branch of the national flameproof equipment inspection authority.

What the certification covers:

- Explosion-proof motor

- Electrical control boxes

- External wiring and cable protection

- Limit switch components

- Overall flameproof housing

What this means for you:

- Compliant with inspection requirements

- Assured performance under tough conditions

- Clear documentation for safety and maintenance teams

Explosion-proof safety is not just about strong parts. It’s about a complete system that works under pressure—literally.

With Exd IIBT4 and Exd IICT4 ratings, Yuantai BCD electric hoists give you proven protection for your team, your equipment, and your operations.

Core Engineering Features

| Feature | Benefit to the Buyer |

|---|---|

| Spark-resistant bronze & SS components | Eliminates hot-spark ignition risk |

| Conical-rotor explosion-proof motors | 2–3× starting torque, no external brake sparks |

| Modular cylindrical-gear reducer | 96 % efficiency, quick swap parts |

| Dual travel speeds (optional) | Precise positioning & fast long runs |

| IP54 enclosures & sealed electrics | Dust/oil ingress protection in refineries |

Performance Highlights: Built for Reliable, Daily Use

The Yuantai BCD explosion-proof electric hoist isn't just safe—it's built to perform steadily in tough environments, day after day. Here's how the key specifications work in your favor.

Duty Group M3: A Perfect Fit for Most Applications

The BCD series falls under Duty Group M3, also known as FEM 1Am–2m.

That means it's designed for:

- Low to medium usage (regular but not continuous operations)

- Moderate load handling across standard shifts

- Ideal for factories, oil depots, chemical zones, and refineries

You don’t need a heavy-duty hoist if your operation doesn’t run non-stop. M3 gives you the balance of durability and cost-efficiency.

Speed Options with Precision Control

Speed matters—not just how fast the hoist lifts, but how smoothly it can stop and position the load.

Standard lifting speeds:

- Single speed: 7 m/min

- Double speed: 7/1.75 m/min (for fine control)

Travel speeds (for trolley-mounted models):

- 20 m/min standard

- Optional dual-speed or frequency inverter for better start/stop control

Creep mode:

- Available on double-speed models

- As slow as 0.8 m/min, perfect for delicate positioning

This gives your team better control when aligning loads or lowering into tight spots.

Oversized Motor Thermal Margin

Unlike many standard hoists that run close to their thermal limits, Yuantai BCD hoists are designed to stay cool—even under full load.

Key performance advantage:

- Motors operate at less than 80% of their rated temperature during continuous operation at full load

Why that matters:

- Longer motor life

- Lower risk of overheating or shutdown

- Stable performance in hot, enclosed, or poorly ventilated areas

You get more uptime, less maintenance, and a better return over time.

Configuration & Custom Options: Built to Fit Your Site

Every project is different. That’s why the Yuantai BCD explosion-proof hoist comes in multiple setups, voltage ranges, and control methods. Whether you’re installing in a low space, working offshore, or replacing an older system, this hoist series adapts easily.

Mounting Options to Match Your Crane Design

You’re not limited to one type of layout. The BCD hoist is available in:

- Low-headroom monorail

For workshops or tunnels with limited vertical clearance.

Keeps lifting height as high as possible in tight spaces. - Double-girder trolley

Ideal for long-span bridge cranes or higher lifting heights.

Offers stable movement and a longer service life. - Fixed-suspension type

Great for stationary lifting applications.

Simple to mount on fixed beams or frames—no trolley needed.

These flexible formats allow easier integration with your plant layout or retrofit plans.

Voltage Options for Global Use

The BCD series supports both standard and custom power supplies:

- Standard: 380 V, 50 Hz, 3-phase。 Suitable for most industrial grids in China and many other countries.

- Optional: 220 V / 440 V, 60 Hz frequency, Special voltages for offshore rigs or remote industrial zones

Just tell us your site’s power setup. We’ll match it to avoid compatibility issues during installation.

Choose Your Control Method

Not all work environments allow the same level of operator access. The BCD hoist supports three different control modes:

- Pendant control (wired)

Simple, direct, and cost-effective. Easy to use for short-range lifting. - Radio remote control

Offers freedom of movement. Useful for keeping operators at a safe distance in hazardous areas. - Cabin control (for large cranes)

Allows operators to work from a protected cabin, especially in heavy lifting or multi-shift operations.

All controls are built with explosion-proof housings where required.

Special Materials for Higher Risk Zones

If your site is in a stricter gas zone—especially IIBT4 or higher—we can upgrade specific components:

- Stainless steel hook (optional)

Prevents sparks from rust or wear

More durable in corrosive environments like chemical plants or offshore platforms

This is a smart add-on if you’re dealing with Zone 1 gas groups or storing volatile chemicals.

With the right mounting, voltage, control, and materials, your explosion-proof hoist should fit into your operation—not the other way around. The Yuantai BCD series offers exactly that kind of flexibility.

5 ton explosion proof hoist main parts and components, customized elecrtric hoist are provided based on your specifications

Typical Applications: Where Safety and Lifting Power Must Coexist

Yuantai’s BCD explosion-proof electric hoists are purpose-built for industrial zones where flammable gases, vapors, or dust could pose serious safety risks. These hoists are not just strong—they're certified for safety in places where a single spark could cause an explosion.

They are used across a wide range of industries and environments:

Petrochemical Tank Farms

- These areas store large volumes of volatile liquids like gasoline or kerosene.

- The risk of gas leaks or vapor release is high, especially during valve or pump maintenance.

- Explosion-proof hoists reduce ignition risks while lifting heavy pump assemblies, filter units, or piping components.

- Typically classified as Zone 1 or Zone 2 with IIA/IIB gas groups.

Practical Note: Tank farms often have height restrictions. The BCD hoist’s compact body fits well under pipelines and pipe racks.

Paint-Spray Workshops

- Found in car manufacturing, appliance production, and metal coating facilities.

- The air often contains fine solvent vapors and mist from spray booths.

- A spark from a normal motor could ignite these vapors.

- BCD hoists allow safe overhead lifting in paint lines, mixing rooms, and prep stations.

Why it works: The flameproof enclosure keeps internal sparks sealed inside—even in areas with lingering vapor concentration.

Gas-Fired Powerhouses

- Used for lifting turbine covers, rotors, burner assemblies, or heat exchangers.

- Boilers and turbines often use natural gas, which introduces flammable atmospheres during maintenance cycles.

- Zones near burners, control rooms, or fuel lines may be classified as Zone 1 or 2.

Added Value: Using an explosion-proof hoist reduces shutdown delays caused by waiting for gas purging or area clearance.

Coal-Seam Methane (CSM) Plants

- CSM facilities extract methane from underground coal seams—methane is a highly explosive gas.

- Typical applications include roof support operations, gas drainage infrastructure, or small parts handling.

- Often classified under Type I explosive gas environments (methane-based).

Important Feature: BCD hoists with Type I explosion protection can work safely in vented underground sections where methane is present but monitored.

In a large South Asian refinery, a 5-ton Yuantai BCD hoist was installed above a blender bay where different fuel blends are mixed. The zone is rated IIBT4 due to the presence of light hydrocarbon vapors. Operators used to rely on chain blocks, which were slow and risky. Since switching to the explosion-proof hoist with radio control, maintenance tasks like pump swaps and agitator checks are completed 40% faster. More importantly, there have been zero gas-alarm incidents related to lifting equipment.

Quick-Reference Specifications

Below is a summary of our most requested BCD explosion-proof hoist models. These specs help with quick planning for layout, power, and runway matching.

BCD Hoist Specs – 3 t / 5 t / 10 t

| Capacity | Lift Height (m) | Lift Speed (m/min) | Motor (kW) | Rail | Weight (kg) |

|---|---|---|---|---|---|

| 3 t | 6 / 9 / 12 | 7.0 / 3.5 | 3.0–3.5 | P24–P30 | 700–950 |

| 5 t | 6 / 9 / 12 | 7.0 / 3.5 | 4.5–5.2 | P30–P38 | 900–1,200 |

| 10 t | 6 / 9 / 12 / 18 | 5.6 / 2.8 | 7.5–8.5 | P38–P43 | 1,600–2,300 |

Notes:

- Dual-speed hoisting standard for better control.

- Rail type depends on trolley load—check runway compatibility.

For 16 t, 20 t, 32 t, 63 t capacities, ask us for detailed spec sheets and layout drawings.

Customized exploison proof hoist with large capacity for sale

Selection Checklist for Buyers

To choose the right Yuantai BCD explosion-proof hoist, review these key factors carefully. Each affects safety, performance, and proper model selection.

1. Hazardous Atmosphere Classification

Confirm the hazardous zone type and conditions:

- Zone Type: Zone 1 (gas likely present) or Zone 2 (occasional gas)

- Gas Group: IIA, IIB, or IIC, indicating explosion risk severity

- Temperature Class: T1 to T4, showing maximum surface temperature before ignition risk

For example, Zone 1, Gas Group IIB, Temperature Class T4 requires a hoist with Exd IIBT4 protection.

2. Duty Cycle and Usage Frequency

Define how often the hoist will be used:

- Daily operating hours

- Number of lifts or starts per hour

- Required FEM duty group, such as M3 for medium use

If the hoist will operate multiple shifts or frequent lifts, consider a higher duty group for better motor life and reliability.

3. Runway Beam and Travel Path

Ensure the hoist matches your structural setup:

- Size and specifications of the runway beam (flange width and thickness)

- Radius of any curved tracks

- Presence of beam end stops or buffers

The trolley wheelbase and wheel size can be adjusted to fit your beams.

4. Power Supply and Control Voltage

Confirm your electrical supply and control systems:

- Main power voltage and frequency (usually 380V/50Hz standard, 220V/440V 60Hz on request)

- Control voltage (commonly 36V or 48V for safety)

- Method for power cable management (festoon system or energy chain)

Correct voltage selection prevents motor overheating and control failures.

5. Space Constraints

Measure installation clearances carefully:

- Available headroom, especially for low-ceiling areas

- End approach distance needed for the hoist to reach work areas

- Type of suspension: fixed, trolley-mounted, or low-headroom custom design

Low-headroom models can reduce hoist height by up to 30%, ideal for tight spaces.

Use our Explosion-Proof Hoist Inquiry Form to guide your technical team through these questions. This helps avoid delays and ensures accurate, fast quotations.

Installation & Maintenance Best Practices

Proper installation and ongoing maintenance are key to ensuring your explosion-proof hoist runs safely and lasts a long time. Follow these steps to protect your investment and keep the system reliable.

Pre-Commissioning: Spark-Test Protocol

Before putting the hoist into operation, conduct a thorough spark test. This checks all moving parts and electrical components for potential ignition risks:

- Inspect all exposed metal parts for friction points.

- Run the hoist through its full range of motion at no load.

- Look and listen carefully for any unusual sparks, noises, or overheating spots.

- Verify that all explosion-proof seals and covers are intact and correctly installed.

Passing the spark test confirms that the hoist meets explosion-proof safety standards and reduces fire hazard risks in hazardous zones.

Monthly Lubrication Map

Consistent lubrication keeps mechanical parts running smoothly and avoids wear that could cause sparks or failures:

- Reducers: Apply the recommended high-grade machine oil regularly. This keeps gears cool and reduces friction.

- Wire Rope: Grease the rope to prevent corrosion and reduce wear from movement over sheaves.

- Limit-Rod Blocks: Lubricate the stop blocks and joints to ensure smooth operation and prevent sticking, which can cause impact sparks.

Keeping a monthly lubrication schedule and logging each maintenance action helps maintain safety and performance.

Annual Recertification for Explosion-Proof Equipment

Explosion-proof hoists require yearly checks to confirm their protective features are intact and compliant with regulations:

- Inspect all flameproof enclosures (Exd covers) for cracks, corrosion, or damage.

- Test all electrical components for insulation resistance and proper grounding.

- Verify that limit switches, overload devices, and braking systems function properly.

- Review and update documentation, including the explosion-proof certificate and maintenance records.

Only certified technicians trained in explosion-proof standards should perform these inspections. Proper recertification ensures your hoist remains safe for use in hazardous environments and meets local and national safety codes.

Keep detailed records of all tests, lubrication, and inspections. Good documentation supports regulatory compliance and helps troubleshoot future issues quickly.

Standards & Compliance Matrix

| Standard | Scope | How BCD Meets It |

|---|---|---|

| GB 3836-2000 | CN explosion-proof design | Full design & acceptance |

| IEC 60079 | Global Ex equipment | Tested to equivalent clauses |

| CE / ISO 9001 | Quality | Factory audit & traceability |

customzied explosion proof hoist with large lifting height for sale to meet your needs

Why Yuantai?

Choosing the right partner for your explosion-proof hoist is as important as choosing the right equipment. Here’s why Yuantai stands out:

Proven Manufacturing Scale and Expertise

Yuantai’s modern factory in Xinxiang, Henan covers a massive 35,000 square meters. This space is dedicated to producing over 1,000 hoists every year, including the BCD series explosion-proof models. Our high production volume means:

- Consistent quality through standardized processes

- Quick turnaround times to meet your project schedules

- Expertise developed from years of manufacturing experience

Certified Quality You Can Trust

All Yuantai hoists come with key certifications that prove their safety and quality:

- CE certification ensuring compliance with European safety standards

- ISO certification reflecting rigorous quality management systems

- Third-party Factory Acceptance Testing (FAT) with video documentation available for buyers

You can witness the testing process firsthand via FAT videos, giving you confidence before your hoist even ships.

Strong Global Support Network

Buying a hoist is a long-term investment, and we back you up with global after-sales service hubs. Yuantai maintains regional support centers in Southeast Asia, the Middle East, and Latin America to provide:

- Fast, local spare parts delivery

- On-site technical support and maintenance guidance

- Responsive customer service tailored to your time zone

No matter where your project is, Yuantai is ready to help keep your equipment running safely and efficiently.

With Yuantai, you’re not just buying a hoist—you’re partnering with a trusted manufacturer dedicated to safety, quality, and global service. That’s why thousands of customers worldwide choose us for their most demanding lifting needs.

If you want, I can help you create customer testimonials or detailed case studies highlighting our after-sales success stories!

FAQ Section

Q: What is the lead time for a BCD explosion-proof hoist?

A: Standard models typically ship within 6 to 8 weeks. Customized orders may take an additional 2 to 4 weeks.

Q: Can the hoist’s certifications be transferred internationally?

A: We provide all necessary documentation for certification transfer, but local authority approval is required.

Q: Are spare parts readily available worldwide?

A: Yes. We stock key parts in service hubs across Southeast Asia, the Middle East, and Latin America for fast delivery.

Q: What warranty do you offer?

A: Our warranty covers 12 months from commissioning or 18 months from shipment, protecting against manufacturing defects.

Q: How do ATEX and GB standards differ?

A: ATEX is a European explosion-proof certification; GB is China’s national standard. We comply with GB and can customize for ATEX.

Q: Do you provide installation and commissioning support?

A: Yes. Remote and on-site support are available through our regional partners.

Q: Can the hoist be customized for special industrial needs?

A: Absolutely. We offer tailored options for voltage, controls, speeds, hooks, and explosion-proof zones.

Ready to enhance safety and performance at your hazardous site?

Request a free hazardous-site lifting assessment today. Our experts will analyze your environment and material handling needs to provide you with a tailored quotation for the Yuantai BCD Explosion-Proof Electric Hoist — typically delivered within 24 hours.

Don’t settle for guesswork. Get the right hoist designed exactly for your gas group, temperature class, and operational demands.Contact Yuantai Crane now to ensure your lifting equipment is both safe and efficient.