Explosion-Proof Hoist vs.Standard Electric Hoist: Key Differences

Understand essential safety, certification & usage differences to choose the right hoist for hazardous or safe environments. Why explosion proof hoist?

Introduction

Electric hoists are machines used to lift and lower heavy items using a motor. They are found in almost every type of industrial facility—factories, workshops, warehouses, power stations, shipyards, and more.

Instead of relying on manual labor, electric hoists make lifting easier, faster, and safer. They reduce the strain on workers, cut down on workplace injuries, and help get jobs done more efficiently. Whether it’s lifting steel parts, heavy tools, containers, or equipment, hoists are a core part of material handling.

Why Electric Hoists Matter in Industry

Electric hoists are not one-size-fits-all. Depending on where you use them, the wrong hoist can lead to big problems—especially when the environment has explosive gas or dust.

In general, electric hoists help industries:

- Lift heavy materials that are too large or unsafe to move by hand

- Improve workplace safety and avoid injuries from manual lifting

- Speed up production processes by reducing handling time

- Keep lifting operations stable, reliable, and repeatable

But the type of hoist you choose must match your work environment. That’s where buyers need to pay close attention.

Why It’s Important to Choose the Right Type

There are two main types of electric hoists: standard and explosion-proof.

A standard electric hoist is built for use in safe, non-hazardous areas. Think of a normal factory, warehouse, or workshop—places with clean air, no flammable gases, and no fine dust floating around.

But some industries work in hazardous environments. This means the air may contain flammable gas, vapors, or combustible dust. These places are usually called Zone 1, Zone 2, or similar, depending on the classification. In these areas, one spark or hot surface can cause an explosion.

This is where explosion-proof electric hoists are essential. They’re built with special enclosures, sealed parts, and anti-spark protection. These hoists don’t just lift—they protect lives and property by preventing accidents caused by sparks, static, or overheating.

Choosing the wrong hoist in a hazardous environment can lead to:

- Fire or explosion

- Worker injury or death

- Equipment damage

- Legal and insurance issues

So this isn’t just a technical detail—it’s a safety-critical decision.

Who Needs to Understand the Difference?

Anyone involved in buying, specifying, or operating lifting equipment should know the difference between standard and explosion-proof hoists. This includes:

- Procurement managers responsible for sourcing equipment

- Maintenance supervisors managing workshop safety

- EHS officers (Environment, Health, and Safety) ensuring compliance

- Engineers designing production systems or expansions

- Industrial buyers in oil & gas, chemical, mining, and grain processing industries

If you work in or around hazardous zones, this knowledge helps you ask the right questions and avoid risky decisions. Even if your current site is safe, it’s worth knowing in case your work expands into a different type of environment later on.

What Is an Electric Hoist?

An electric hoist is a motor-driven device used to lift, lower, and move heavy materials vertically or along a beam. It works by winding a wire rope or chain around a drum or through sprockets, powered by an electric motor.

Electric hoists are an essential part of many industrial operations. They are used anywhere that lifting or moving heavy loads is part of the job. Instead of depending on manpower or slow manual winches, electric hoists make the job faster, safer, and more efficient.

Basic Function and Where They’re Used

At the core, electric hoists are built to:

- Lift and lower loads vertically

- Control lifting speed and position

- Support repetitive, heavy-duty lifting tasks

They can be operated by:

- Pendant push-button controllers (wired to the hoist)

- Radio remote controls (wireless for more freedom)

- Automated systems (used in advanced production setups)

You’ll commonly find electric hoists in:

- Steel factories – lifting molten ladles, steel billets, rolls, or structural parts

- Heavy machinery workshops – moving engines, assemblies, or large tools

- Chemical plants – safely handling barrels, pipes, or valves (especially in explosion-prone zones)

- Food and beverage industries – cleanroom-rated models used in packaging or process equipment maintenance

- Construction sites – temporary setups for lifting steel beams or equipment

- Mining operations – handling tools, equipment, or ore bins

- Shipbuilding yards – lifting engines, propellers, hull frames, and outfitting parts

Wire Rope Electric Hoist

This type uses a steel wire rope wrapped around a grooved drum. The motor drives the drum, which pulls the rope and lifts the load.

Key Features:

- Designed for higher load capacities (usually from 1 ton up to 50 tons or more)

- Offers smooth and fast lifting, often with dual speed control

- Suitable for frequent or continuous use in demanding environments

- Better suited for long lifting heights

- Usually installed on double girder cranes, gantry cranes, or custom monorails

Common Applications:

- Heavy steel handling in mills

- Large equipment assembly lines

- Ship component lifting

- High-volume production floors

Special Note: Explosion-proof wire rope hoists are often used in petrochemical, mining, and gas industries because they can be built with sealed enclosures and spark-resistant parts.

Chain Electric Hoist

This type uses a high-strength alloy steel chain passed through a lifting sprocket driven by the motor.

Key Features:

- Best for lighter loads (typically 0.5 ton to 5 tons)

- Ideal for short lifting distances (under 6 to 12 meters)

- More compact and portable compared to wire rope hoists

- Easier to install and maintain

- Can be suspended from I-beams, fixed hooks, or used on manual/electric trolleys

Common Applications:

- Maintenance workshops

- Smaller parts manufacturing

- Assembly stations

- Garage or small factory lifting tasks

Bonus Tip: Many chain hoists are available in explosion-proof versions, but usually for lower load capacities. These are used in Zone 1/Zone 2 hazardous environments like paint shops, gas storage areas, or dust-prone processing plants.

How to Choose Between Them

| Feature | Wire Rope Hoist | Chain Hoist |

|---|---|---|

| Load Capacity | Medium to heavy (1–50+ tons) | Light to medium (0.5–5 tons) |

| Lifting Height | Long (up to 60m or more) | Short to moderate (up to ~12m) |

| Lifting Speed | Fast, smoother control | Slower, more basic control |

| Duty Cycle | Frequent/continuous use | Intermittent/light-duty use |

| Installation | Requires stable structure | Compact and easier to install |

| Explosion-Proof Option | Available in both types | Available, mostly for lower loads |

To sum up:

- Go with wire rope if you need strength, speed, and long lift height.

- Choose chain if you need something simple, small, and easy to install.

- If you're working in hazardous areas, make sure the hoist type—wire rope or chain—has proper explosion-proof certification.

Defining Explosion-Proof Hoists

So, what exactly does “explosion-proof” mean when we’re talking about electric hoists?

In short, an explosion-proof hoist is specially built to avoid causing any spark, flame, or heat that could ignite flammable gases, vapors, or dust in a work environment. It’s not just about a rugged outer shell—it’s about the whole system being safe to use in risky places.

What Makes a Hoist “Explosion-Proof”?

A hoist becomes explosion-proof when it is designed and built to contain or prevent any ignition source that could cause an explosion. This includes internal sparks, hot surfaces, and static electricity.

To achieve this, explosion-proof hoists usually have:

- Flameproof enclosures around motors, brakes, and electrical panels

- Sealed control cabinets and wiring systems

- Anti-spark materials like copper-alloy hooks or brass wheels

- Temperature control features to keep surfaces cool during operation

- Grounding protection to reduce static discharge risks

All of these features work together to ensure the hoist won’t ignite anything in the air around it—even if the environment is full of flammable gas or fine dust.

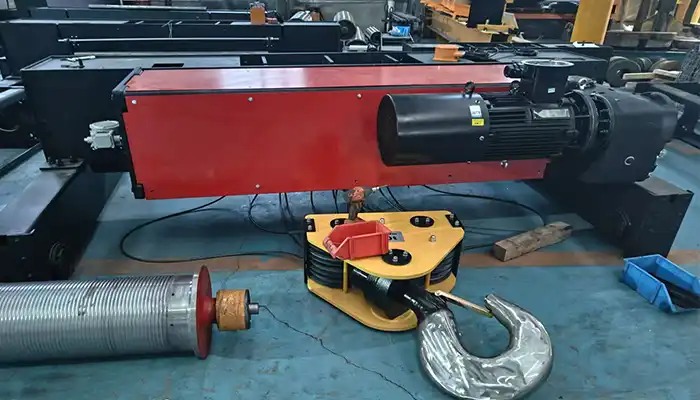

Explosion proof wire rope electric hoist

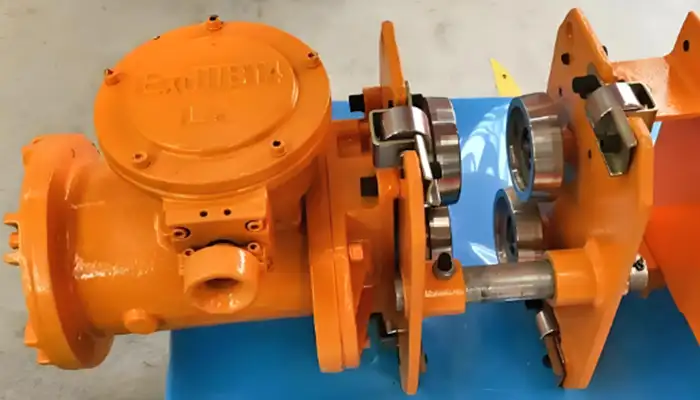

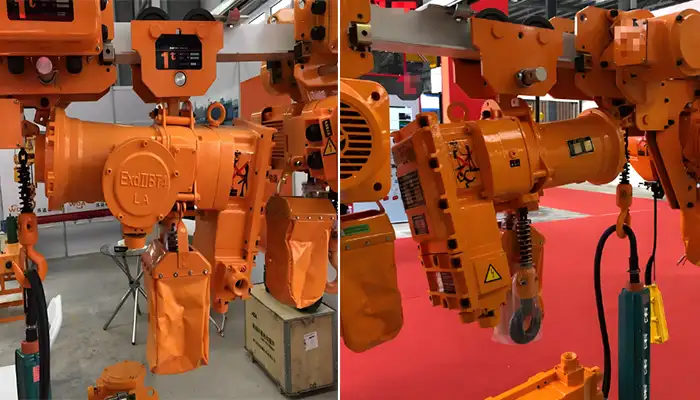

Explosion proof electric chain hoist

Certified Protection for Hazardous Environments

Explosion-proof hoists must meet specific safety standards. These aren’t optional—they are legal and safety requirements in most countries and industries. When a hoist is certified, it means it's been independently tested and approved for use in hazardous zones.

Common certification systems include:

- ATEX (Europe) – Based on EU Directive 2014/34/EU

- IECEx (International) – Follows global IEC standards for explosive atmospheres

- NEC/CEC Classifications (USA/Canada) – Defines Class I, II, III Divisions and Groups for gases and dust

- GB Explosion-Proof Standards (China) – Used for domestic compliance and exports

A buyer should always ask:

What certification does this hoist meet?

Because using the wrong equipment in a hazardous zone can lead to serious accidents—or even legal issues.

Where Are Explosion-Proof Hoists Used?

These hoists are used in places where explosive atmospheres might form during normal work activities. That includes industries where gases, vapors, or combustible dusts are common.

Some typical work environments:

- Petrochemical plants – for lifting pumps, valves, or pipes in areas with gas leaks

- Oil & gas refineries – where flammable vapors are always present

- Underground mining operations – with methane gas or coal dust

- Paint shops and spray booths – where solvent fumes are present

- Chemical and fertilizer plants – with volatile raw materials

- Grain silos and feed mills – where fine dust can ignite easily

- Battery production lines – especially lithium or chemical processes

- Waste treatment plants – with biogas or explosive byproducts

Important Reminder for Buyers:

If your hoist will be used in a Zone 1, Zone 2, or Class I/II hazardous area, you must choose a hoist that’s properly certified. Even a small spark from a standard motor or brake can cause disaster.

Standard Electric Hoists Explained

A standard electric hoist is the most commonly used type of hoist in industrial lifting. It’s designed to work in safe, non-hazardous environments—meaning there’s no risk of flammable gas, vapor, or dust igniting in the air.

These hoists are built for general-purpose material handling, making them ideal for many industries that don’t require special safety features. Because they don’t need explosion-proof protection, they are simpler, lighter, and more affordable.

Typical Use in General Industrial Settings

You’ll find standard hoists installed almost everywhere that doesn’t have strict hazardous area classifications. Some typical work environments include:

- Manufacturing plants – Used to lift raw materials, parts, tools, and assemblies along the production line.

- Warehouses and distribution centers – For moving heavy boxes, machinery, and palletized goods in storage or loading areas.

- Mechanical and auto repair workshops – Common for lifting engines, transmissions, or large tools for maintenance work.

- Fabrication and assembly shops – Used to move beams, metal sheets, or fabricated components during welding and assembly.

- Construction yards and equipment rental depots – Supporting temporary lifting needs in low-risk zones.

- Food processing and packaging – Only when there's no explosive flour or sugar dust present, and environments are dry and ventilated.

In these places, there's no danger of an explosive atmosphere forming under normal operation. So, a standard hoist provides enough safety while keeping the system simple and efficient.

Why Standard Hoists Are Popular

There are several reasons why standard hoists are widely used in industry. First, they are lower in cost compared to explosion-proof versions. That’s because they use normal enclosures, standard electrical components, and don’t require special materials to prevent ignition.

Second, the design is more straightforward. Most standard hoists are easier to install, inspect, and maintain. Replacement parts are also easier to find, and technicians are more familiar with standard models.

Third, there’s a wide range of options available. You can choose from:

- Wire rope or chain hoists

- Lifting capacities from 500 kg to 50 tons or more

- Various lifting speeds

- Pendant control, radio remote control, or integrated PLC systems

- Trolley-mounted or fixed models

Because there’s no need for protective enclosures or advanced sealing, standard hoists are often lighter in weight, making them easier to integrate into cranes or monorail systems.

It’s important to understand that standard hoists are not suitable for every setting. Just because a plant looks clean or the job seems small doesn’t mean it’s safe for a standard hoist.

If your operation involves:

- Combustible dust (e.g., grain, flour, sawdust, metal powders)

- Flammable gases or vapors (e.g., solvents, fuels, propane, chemicals)

- Frequent temperature fluctuations that cause vapor buildup

Then your environment may be classified as hazardous. In these cases, a standard hoist is not enough—and using one could lead to a serious fire or explosion risk. Always consult your safety team or refer to local regulations to be sure.

Key Differences: Explosion-Proof vs. Standard Hoists

| Feature | Explosion-Proof Hoist | Standard Hoist |

|---|---|---|

| Motor and Enclosure | Flameproof, sealed enclosures | Standard casing |

| Wiring and Components | Sealed, anti-spark, heat-resistant | General insulation and wiring |

| Compliance and Certification | ATEX, IECEx, national standards | No hazardous duty certification |

| Control System | Intrinsically safe or flameproof control | Regular push-button pendant or remote |

| Cost | Significantly higher | More economical |

| Maintenance Requirements | Strict inspection and service | Standard schedule |

| Typical Applications | Hazardous gas/dust zones | Safe, open environments |

When Should You Choose an Explosion-Proof Hoist?

Not every lifting operation needs an explosion-proof hoist—but when the risk is real, making the right choice becomes critical. If your facility has flammable gases, vapors, dust, or fibers in the air, you should seriously consider using explosion-proof equipment—and in many cases, it’s not just a recommendation; it’s a requirement.

Flammable Atmospheres Are Present

The most important factor is the operating environment.

If your hoist will be used in areas where flammable substances may be present—either continuously or occasionally—you must use explosion-proof models. These substances might not always be visible or active, but even small leaks or fine dust particles can create an ignition risk.

Typical flammable conditions include:

- Gas leaks from pipelines, pumps, or storage tanks

- Solvent vapors in paint booths or chemical processing areas

- Dust clouds in grain storage, flour mills, or metal grinding operations

- Oil mist or fuel fumes in engine maintenance shops

- Coal dust or methane gas in mining and power plants

Even a standard electric spark from a hoist motor or brake system can ignite these materials if the environment is not controlled.

Legal and Safety Compliance Requirements

Explosion-proof hoists aren’t just about preventing accidents—they’re often required by law and regulation.

If your facility falls under a hazardous area classification, local safety codes may mandate the use of certified explosion-proof lifting equipment. Using a standard hoist in these areas can lead to:

- Fines or legal penalties from safety regulators

- Shutdown orders during inspections

- Delays in permits or insurance approvals

- Invalidated warranties or contracts

Relevant standards and authorities to consider:

- ATEX Zones 1 and 2 (Europe)

- IECEx certification for international use

- NEC Class I, II, III Divisions (USA/Canada)

- China’s GB explosion-proof equipment standards

- Industry-specific rules (e.g., oil and gas safety codes)

If you're unsure, check with your local safety officer or an industrial engineer before making a purchase.

Insurance and Internal Safety Policies

In many companies, it’s not just about following laws—it’s also about meeting insurance requirements and internal safety rules.

Insurance providers may:

- Refuse to cover explosion-related incidents if unapproved equipment was used

- Increase premiums if non-compliant hoists are installed in risky zones

- Request certification documents for every lifting device in hazardous areas

Some corporations also have strict safety protocols that go beyond legal compliance. Their engineering or EHS (Environment, Health & Safety) teams may only allow explosion-proof certified equipment in certain zones, regardless of frequency of use.

If your company has a zero-incident policy or handles flammable materials—even occasionally—it’s safer to go with certified equipment.

High Risk of Catastrophic Failure

Finally, explosion-proof hoists are essential when the cost of a mistake is just too high.

In some environments, even a single spark can result in:

- Fires and large-scale property damage

- Injuries or fatalities

- Environmental contamination

- Loss of production and business interruption

- Damage to brand reputation

If any of those outcomes would be unacceptable in your operation, the added investment in explosion-proof equipment is worth it.

It’s not just about meeting rules. It’s about peace of mind—knowing your lifting system won’t become the weak link in your facility’s safety chain.

Quick Checklist — Should You Consider an Explosion-Proof Hoist?

You likely need one if:

- Your environment is classified as Zone 1, Zone 2, or NEC Class I/II/III

- You store or process flammable gas, dust, or vapor

- You’ve had gas leaks or dust buildup in the past

- Your insurance or safety team requires certified equipment

- You want to prevent even the slightest chance of ignition

Buyer Checklist: Choosing the Right Hoist

When buying an electric hoist—especially for industrial use—making the right choice goes beyond just lifting capacity. Safety, environment, and long-term reliability should always come first. This checklist helps you cover the key points before making a final decision between a standard or explosion-proof hoist.

Define Your Working Environment

Start with the basics: where will the hoist be used?

- Is the environment clean and dry, or does it have flammable gases, vapors, or dust?

- Is it an open warehouse, a chemical plant, a grain silo, or a paint shop?

- Are there fumes during daily operations, or only during occasional maintenance?

If there’s even a chance that combustible substances are present, you’re likely working in a hazardous environment, and an explosion-proof hoist may be necessary.

Identify Hazardous Zones or Classifications

In hazardous areas, knowing the zone or class is critical. These classifications tell you how often explosive atmospheres are present, and what kind of explosion risk exists.

Depending on your country or industry, use the correct reference:

ATEX Zone 1 or Zone 2 (Europe and global users)

- Zone 1 means flammable gas is likely during normal operations

- Zone 2 means flammable gas is unlikely, but possible in abnormal situations

IECEx Zones (International standard similar to ATEX)

NEC/CEC Class I, Division 1 or 2 (North America)

- Class I refers to gas or vapor hazards

- Division 1 means presence is regular

- Division 2 means presence is occasional

You must choose a hoist that is certified for the correct classification. Using uncertified equipment in hazardous areas is not only dangerous—it’s illegal in most jurisdictions.

Check Required Certifications

Explosion-proof hoists come with strict certification labels to ensure safety.

Depending on your project location, look for one or more of the following:

- ATEX-certified (for example, II 2G Ex db IIB T4 Gb)

- IECEx-certified for global use

- NEC/CEC compliance for North America

- GB/China Ex certification for operations in China

Each marking gives details about the explosion group (such as IIB for typical gases, or IIC for higher risk gases like hydrogen), temperature class (like T4 for max surface temperature 135°C), and protection method (such as flameproof enclosure).

Don’t skip this step. Always ask for a certificate and confirm it matches your zone rating and substance group.

Know Your Load and Duty Cycle Requirements

Next, match the hoist’s lifting capacity and duty rating to your workload.

Key things to consider:

- Maximum load weight you’ll lift (always add a 10 to 25 percent safety buffer)

- Lifting frequency—how often will the hoist operate per day?

- Duration of each lift—are they short lifts or continuous lifting?

- Is the application light-duty, medium-duty, or heavy-duty?

For example, a warehouse lifting pallets once an hour may only need a light-duty standard hoist. A petrochemical facility with daily pipe handling might require a heavy-duty, flameproof model rated for frequent starts and stops.

The wrong duty cycle can cause early motor burnout, brake failure, or overheating—especially in hazardous zones where equipment must stay sealed and cool.

Determine Lifting Height and Control Preferences

Look at the physical setup of your lifting site:

- How high does the load need to travel?

- Is there limited headroom or ceiling space?

- Do you need a low-headroom hoist or a trolley-mounted design?

- What type of controls do you prefer—pendant push-button, radio remote control, crane cab control, or integrated PLC systems?

For hazardous zones, controls must also be explosion-proof, which adds cost and complexity. Make sure to specify your needs early to avoid compatibility issues later.

Balance Budget vs. Safety Requirements

Explosion-proof hoists cost more than standard models. That’s a fact.

The price difference comes from sealed and flameproof motor housings, anti-spark materials, certified electrical components, and strict inspection and testing.

That said, don’t let budget override safety. If your hoist operates in or near a classified zone, the risk of using a cheaper, uncertified model is just not worth it.

To make a smart investment:

- Request both standard and explosion-proof quotes

- Compare lifecycle cost, not just upfront price

- Check for inspection frequency, replacement part cost, and service availability

If your site includes both safe and hazardous zones, you might need a combination of hoist types, each suited to its area. That’s a more cost-effective and compliant approach than trying to make one hoist fit all purposes.

Conclusion

Choosing the right electric hoist depends mostly on where and how you will use it. Not all hoists are the same, so it’s important to understand your environment and safety needs before making a decision.

Explosion-Proof Hoists

If your work area has flammable gases, dust, or vapors, explosion-proof hoists are designed specifically for these risky conditions. They help keep your workplace safe and meet strict safety rules. Here’s what you need to know:

- Made for places with flammable gases, dust, or vapors.

- Built to prevent sparks or heat that could cause an explosion.

- Must meet strict safety rules and certifications.

- Using one in these areas is required by law to keep everyone safe.

Standard Electric Hoists

For workplaces without explosion risks, standard hoists are usually the best choice. They are simpler and less expensive but still reliable for general lifting tasks. Consider these points:

- Used in safe, regular work areas like warehouses and factories without explosion risks.

- Simpler design and easier to maintain.

- Usually cost less than explosion-proof hoists.

- Great for everyday lifting tasks in normal environments.

Before you buy, it’s important to make sure your hoist choice follows safety rules and fits your workplace needs. Taking these steps protects your workers and your investment. Keep these tips in mind:

- Always check safety rules and talk to your safety officer before buying.

- Make sure the hoist fits the hazards and rules of your workplace.

- Buying the right hoist helps avoid accidents, fines, and costly downtime.

- The right hoist keeps your workers safe and your work running smoothly.

In short, know your environment and safety needs first. Then match those with your lifting needs and budget. This way, you’ll pick the best hoist for your business while keeping everything safe and efficient.